Auto Parts Inspection for Machine Vision Applications

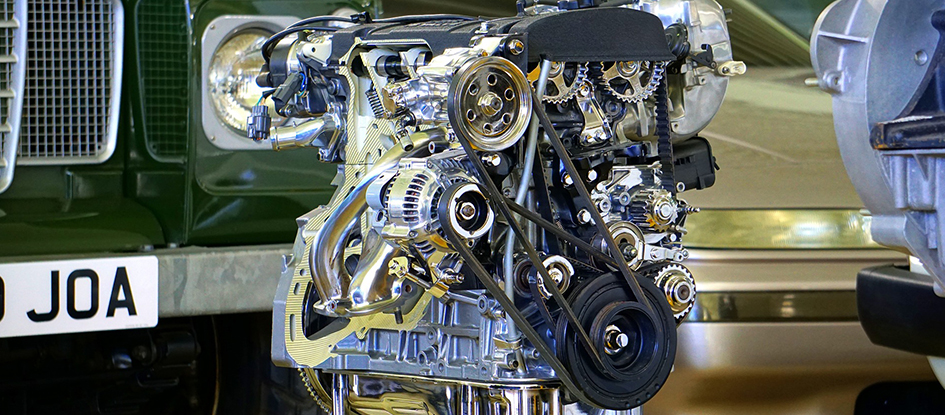

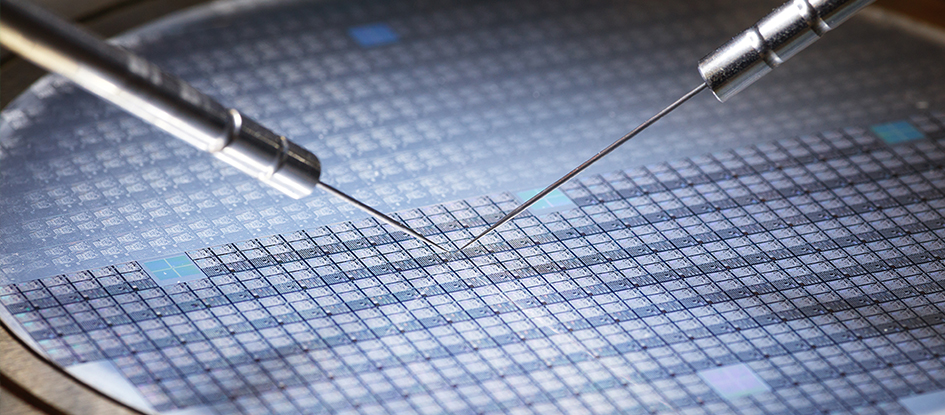

The low magnification and large field of view bi-telecentric lens has good uniformity in the center of the field of view and around it and has extremely low distortion imaging, which is very suitable for high-precision workpiece appearance inspection and size measurement. Detection object: Auto parts inspection Testing requirements: Whether the pins are crooked Hole […]

Auto Parts Inspection for Machine Vision Applications Read More »