The most common application of bi-telecentric lenses is to measure precision mechanical parts. Among them, many precision mechanical parts are produced for the automotive industry, such as engine shafts, valves, pistons and other parts. Components like pipes or extruded aluminum profiles are usually controlled offline by dedicated machines. Telecentric lenses are often used to control the size of small mechanical parts.

Detection object:

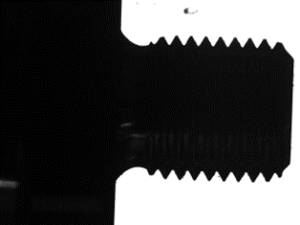

Auto parts screw thread detection

Testing requirements:

- Cross-surface thread arc detection

- High precision

Solution: DTCM125-26 (DTCM series double telecentric lens) + DTCL-26-1W-G (telecentric parallel backlight) +1/2.5″ 5M camera

Test results:

- The resolution of the center and edge of the field of view is the same, and the distortion is extremely low (0.06%);

- With parallel backlights, compared with traditional flat-panel backlights, the edges are sharper and the gray transition pixels are fewer. At the same time, the brightness of the center and the periphery of the field of view remains uniform, which maximizes the high resolution characteristics of the lens and greatly improves the accuracy of measurement;

- The effective aperture is F6.8, while the resolution is guaranteed, the depth of field also meets the project requirements.

Measured renderings: