About

VICO Imaging®

Headquarters

Shenzhen Office

Hong Kong Office

Overseas Distribution

Seoul Office

Trade Show

Huizhou Office

R&D and Industrial Park

We have project-based partnerships with industry leaders such as Keyence and Cognex in China region, and CCS in Southeast Asia region. Our cutting-edge design also allows our lenses to be a part of highly advanced semiconductor packaging technologies such as CoWoS.

5,600+

Served Customers

8,500+

Developed Products

1.8m+

Lens Units Sold

As our business expanded, we established branch offices to better serve our customer demands across various regions. Our Hong Kong Office was established in 2013, followed by our Seoul Office in 2018. Our headquarters remains in Shenzhen, catering to our global clientele, while our factory continues to operate in the industrial park in Huizhou.

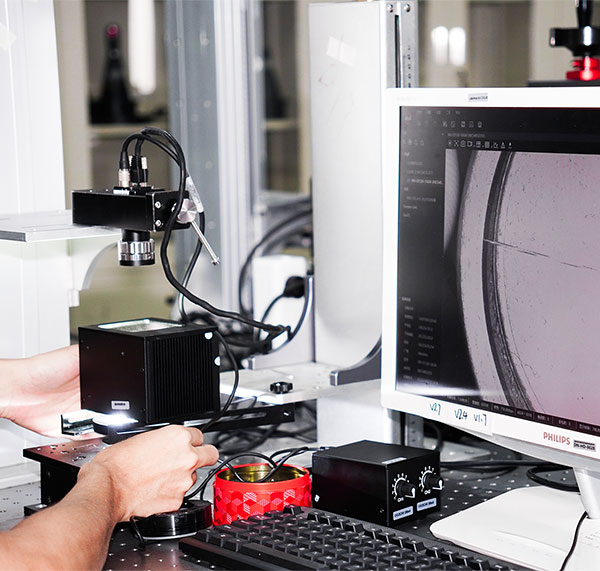

A Corner of the Lab

Testing on Customer Samples

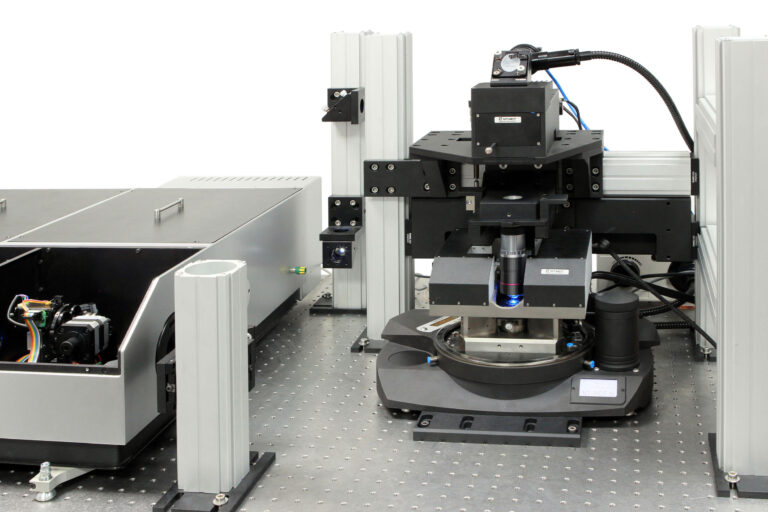

Line Scan Bench

Featured Brands

Our Footprints

VICO Imaging® Unveils Cutting-Edge Tech at Smart Factory + Automation World 2024!

VICO Imaging® to Debut Advanced AOI Lens Series at Image Sensing Show 2023.

VICO Imaging® is known for providing cutting-edge technology in the machine vision industry for various applications such as automotive, security and surveillance, consumer electronics, metal, semiconductor, and so on. During the Image Sensing Show 2023.

VICO Imaging® Attends Korea Vision Show 2023, Showcases Latest AI-based Imaging Technologies

Breaking Into the Japanese Market: VICO Imaging® at Exhibition in Japan

Our Service

Customer Communication

Partnership Building

Equipment Showcase

Excellent Service

Fast response

Our sales team will respond within 24 hours on work days.

Easy sampling

We have service locales and sample storage in global regions including Germany, Japan, Korea and more.

Fast shipping

We ship within a week upon order.

Expert testing

We have full teams of experts with well-equipped labs in China, South Korea and more regions to provide professional testing for our clients.

Warranty

We provide a one-year warranty for our products together with professional technical support from our team.

Quality Products

Special designs

We have multiple specially-designed products including 360° outer and inner wall inspection lens, multi-faceted inspection lens, flat lens, corner lens, spectroscopic lens, etc.

Various series

We have multiple lens series such as DTCM, DTCA, WWK, WWH, WWT, MFA, WWL and more. Together we have over 1,500 different lenses for you to choose from.

Quality guaranteed

We have strict manufacturing inspection for our dust-free production line. We could provide reliability parameters from our testings including humidity, shock, water pressure, pressure, vibration etc. if needed.

Supply chain

Our 45,000pcs/month capacity production allows us to guarantee shipping within one week; for the past three years our average annual shipment volume is 200,000pcs/year. Our material warehouse is always stocked ready for production demands.

Technical capability

We have engineer teams consist of optical experts all with over 10 years in this field.

Extensive Customization

Our Office

Shenzhen

Headquarters

5A 1303, Logan Carat Complex, Longhua District Shenzhen, China

+86 0755-29977399

Huizhou Office

(R&D and Industrial Park)

+86 0752-5118988

Hong Kong Office (Overseas Distribution)

253-261HennessyRoad, Wanchai,

+86 0755-29952252

Seoul Office

+82 2-897-8988