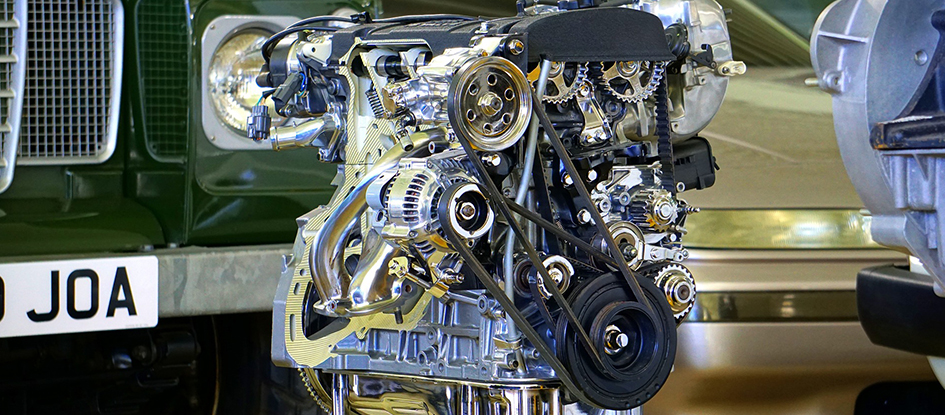

How Does Machine Vision Improve OCR in Automotive Manufacturing?

Due to their unique sizes, shapes, and weights, battery packs and pouch cells are hard to separate. It usually involves human sorting. Thus, it is crucial to examine the potential for classifying batteries by extracting text from the batteries’ images using deep learning object character recognition (OCR). After that, we can compare this text to […]

How Does Machine Vision Improve OCR in Automotive Manufacturing? Read More »