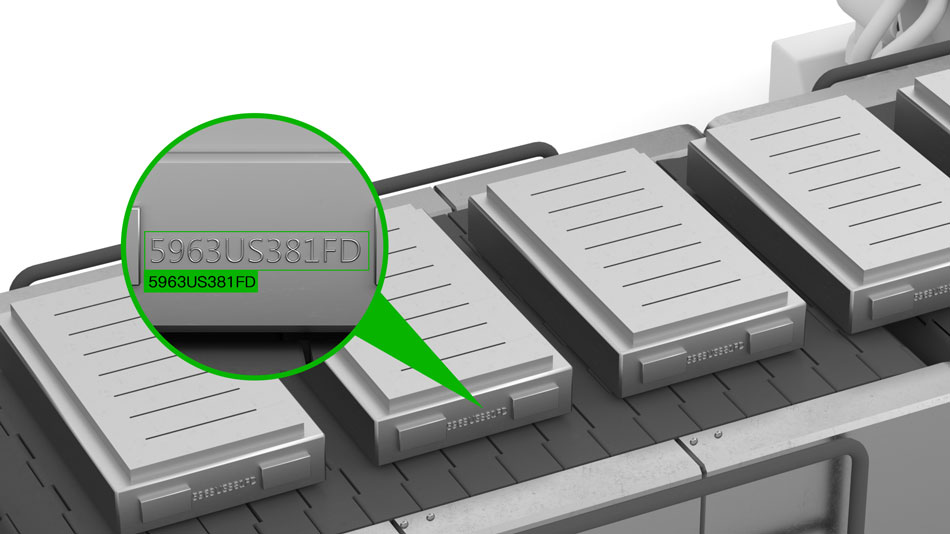

Due to their unique sizes, shapes, and weights, battery packs and pouch cells are hard to separate. It usually involves human sorting. Thus, it is crucial to examine the potential for classifying batteries by extracting text from the batteries’ images using deep learning object character recognition (OCR). After that, we can compare this text to a database of known text information indicating battery types.

Due to their unique sizes, shapes, and weights, battery packs and pouch cells are hard to separate. It usually involves human sorting. Thus, it is crucial to examine the potential for classifying batteries by extracting text from the batteries’ images using deep learning object character recognition (OCR). After that, we can compare this text to a database of known text information indicating battery types.

Furthermore, the text IEC code found on lithium-ion batteries can be examined to categorize them. Thus, it shows the capability of a machine vision system to sort any object based on the text.

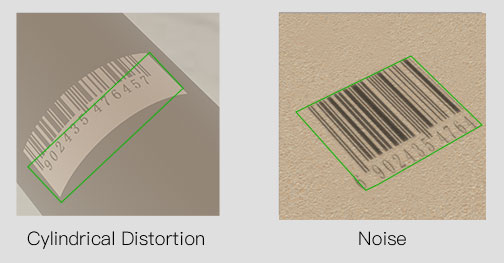

The alphabetic codes inscribed at the bottoms of batteries must be easily located and deciphered by manufacturers. A machine vision system may struggle to identify and distinguish characters in a lit or glaring environment, particularly if the characters are distorted. Thus, to correctly decode characters, an inspection system must be able to cope with these difficulties.

This post is for those in the automobile sector who are interested in OCR and Machine Vision. Do you want to employ this lethal combo to improve your production processes?

Then let’s explore what battery OCR is, how it differs from traditional OCR, and how it can be used in a production line. Moreover, you will also learn the application of a lens in OCR.

Optical Character Recognition on a Battery: What Does It Mean?

Any picture with writing on it may be transformed into text data that a computer can read using optical character recognition (OCR). It is also known as text recognition technology.

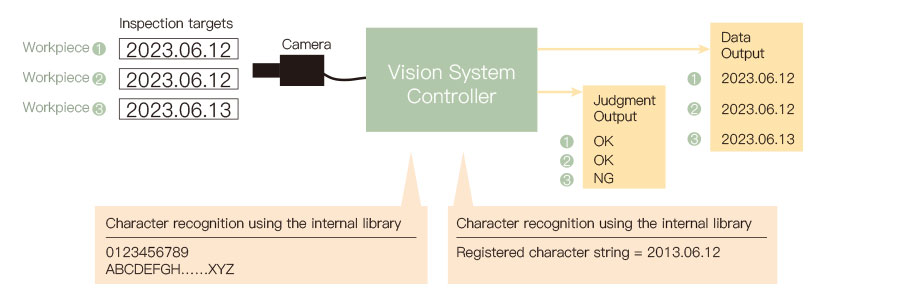

Image pre-processing, character recognition, and post-processing are the three main components of an OCR system.

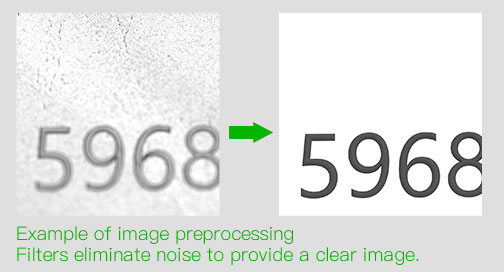

Image Pre-processing

Image pre-processing helps to enhance text identification by removing image noise and increasing the contrast between the backdrop and text.

Character Recognition

It involves assembling a string of characters to form a word or phrase, at which point pattern recognition or feature detection techniques may be used.

Image Post-processing

Filtering out false positives and noisy outputs, merging identified entities with their derived meaning, verifying the accuracy, etc., are all examples of post-processing tasks.

Optical character recognition (OCR) facilitates digitizing paper documents without requiring time-consuming and error-prone human data input. That’s why many companies use OCR to streamline and automate their processes.

OCR’s results not only serve as the foundation for cognitive computing, machine translation, and text-to-speech technologies, but also for the editing and compact storage of electronic documents.

Recent developments in machine learning (ML) have greatly facilitated the expansion of OCR’s use cases. The OCR machine learning method may be used in any manufacturing setting where identifying and transforming text is required, provided that sufficient training data is available.

How Does OCR Technology Work?

The OCR technology consists of a combination of hardware and software. It scans characters using pattern images.

Additionally, it offers us recognizable texts by making some assumptions about the characters. OCR may employ one of two methods to interpret the information contained in a picture.

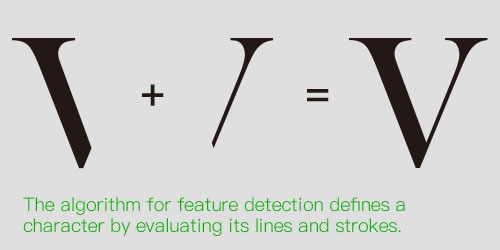

Feature Detection

Intelligent character recognition and feature extraction are methods used in OCR software. Feature detection can recognize not only printed but also handwritten text. This feature lets it see the text written on specific parts, improving precision.

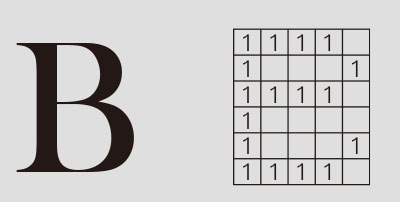

Pattern Recognition

We also call it matrix matching or pattern matching. A pattern recognition algorithm allows technological equipment to recognize various written texts by comparing an item to a character library in the software.

When OCR software sees the shapes aligning with objects, it may read the data and provide a detailed report accurately.

What Are the Benefits of Using Machine Vision for Battery Optical Character Recognition?

The fundamental advantage of optical character recognition (OCR) technology is the ease with which text is searched, edited, and stored, greatly reducing the time and effort required for data input. With OCR, manufacturers can scan components and change them into electronic files that can be kept on their computers, laptops, and other devices.

Some advantages of using OCR technology are as follows.

Improved Accuracy

Software-based character recognition is more accurate than human-based methods because it removes the possibility of human mistakes.

Make Things Go Faster

Manufacturing operations can run faster thanks to the technology’s ability to transform unstructured data into searchable information.

Cost-Effective

The low resource requirements of OCR technology mean lower processing costs, which in turn mean lower overhead for manufacturers.

Improved Productivity

With all relevant information at their fingertips, workers are less likely to get distracted from their primary responsibilities, which in turn increases productivity. The proper vehicle must get all attachments and pieces in the exact sequence during assembly.

Manufacturers often stamp serial numbers into the components to prevent errors, but OCR may streamline this procedure. Optical character recognition technology allows factories to scan any serial number on the components without disrupting the manufacturing cycle.

Manufacturers can capture data from each component as it goes down their conveyor belt using video cameras and industrial lenses integrated with optical character recognition technology.

Furthermore, OCR offers an efficient method to monitor the handling of raw materials and packaged goods to boost productivity.

What Are the Common Challenges Related to Battery OCR?

There are certain limitations on the effectiveness and utility of OCR systems. Misreading letters, skipping unreadable characters, and combining text from neighboring columns are common OCR problems.

Aligning and rotating the object, reducing blur, adding filters, and erasing non-character features are the most typical ways to solve these problems.

Uniform Lighting Conditions

When capturing an object in the production line, unexpected shadows and contrasting lighting can result in an unclear picture. As a result, precise detection, segmentation, and text recognition become much more challenging.

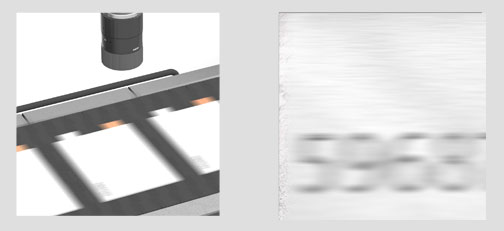

Blurring

When capturing an object in motion, the camera’s sensor constantly exposes it to a new scene if the shading rate is not high enough. As a result, it is typical to see blurring in the pictures.

Fonts

Overlapping characters are a potential problem for optical character recognition (OCR) operations. It usually occurs when batteries are printed using italic or script font styles. It isn’t easy to do text recognition because characters from different fonts have huge variances and numerous pattern sub-spaces.

Distortion

OCR has trouble reading text on irregularly shaped items.

Challenging Background

It is common for OCR systems to start with a color or greyscale image and then convert it to black and white. It is done so that black-and-white text is more easily distinguished from its backdrop, and blurring is minimized.

Background features, such as little dots or sharp edges, might be mistaken for letters and skew text recognition results. These days, OCR methods rely on computer vision-based algorithms trained on augmented data sets to help them better distinguish text from the backdrop. Thus, elements like dots, lines, stains, etc., can be distracting.

Skewness (Rotation)

In an OCR system, photos in which the object is misaligned or skewed will provide subpar results. Thus, de-skewing methods, such as the RAST algorithm, Fourier transformation, etc., must be applied to the pictures first.

VicoImaging’s mission is to provide its customers with cutting-edge vision technology that suits complex industrial environments. Using state-of-the-art technology, we have designed and manufactured superior industrial lenses as part of a comprehensive solution for Optical Character Recognition (OCR).

We often recommend our FA lens for OCR of different metal surfaces used in the automotive industry. Not only do these lenses provide a high level of light input, but they also accept reflection from different angles. As a result, our FA lenses offer incredible detection speed and contrast.

Why Should Automobile Industry Consider OCR Cameras, Industrial Lenses, and Software?

It’s a difficult procedure to make even a single car. Every component and accessory must find its way to the appropriate place and at the right time.

Stamping items with serial numbers has become standard practice in most sectors today. Part numbers, whether embossed or printed, may be read dynamically in these factories thanks to OCR Solutions’ technology.

Misidentification of components can stop production, and improper placement of components can shut down a whole manufacturing line. Thus, manufacturers must ensure no information is lost, and all components are appropriately labeled by combining video cameras with optical character recognition software and technology.

In short, proper identification is essential for a secure and efficient workplace. Using software in conjunction with an OCR camera equipped with an industrial lens is a technological advancement that benefits the company.

Combining a camera, industrial lens, and software can prepare the data for further digital processing. It can handle objects of any size and transparency. Moreover, this combination saves time and effort by decreasing the need for human inspection and filing. The result is a tremendous boost in output. Besides, fewer mistakes mean a safer working environment.

How to Improve OCR Accuracy?

Concerns about OCR’s reliability have been raised in the past. Optical character recognition technology has come a long way after that, thanks to recent advancements in the machine vision industry.

Sub-pattern Registration

Multiple pattern registrations for a single character result in more reliable identification. You can avoid identification failures caused by incompatible fonts by adding them to the database as sub-patterns.

Automatic Fitting

For optimal extraction, automated fitting makes small adjustments to characters automatically. Correcting minor status differences between characters before verification increases the correlation level.

Enhancement Filters for Images

The accuracy of character inspection may deteriorate when the backdrop of the marking contains patterns or is composed of metal or other shiny material. Applying image enhancement filters allows consistent character inspection even when reading is challenging because of these and other reasons.

Using Advanced Lenses

If you’re using an advanced camera for machine vision, you should have equally advanced lenses designed for its sensor. The most crucial selection factors in lenses are the resolution, picture quality requirements, and field of view. Lenses with a fixed focal length are often employed in machine vision applications.

The OCR application in the automotive industry requires recognition accuracy. So, you need to check out the resolving power of the lens. Our 1.2” FA Lens from the FA lens series offers excellent uniformity and a 75mm focal length. It allows for better contrast, which is the basic requirement for improving recognition accuracy.

| Image | Model NO. | Focal Length(mm) | Aperture | Max.Sensor Format | MOD(mm) | Filter Size | TV Distortion | Mount |

|---|---|---|---|---|---|---|---|---|

|

MFA121-U18 | 18 | 4.0-16 | 1.2″ | 100 | M35.5xP0.5 | <0.5 % | C |

|

MFA121-U25 | 25 | 4.0-16 | 1.2″ | 150 | M35.5xP0.5 | <0.01 % | C |

|

MFA121-U35 | 35 | 4.0-16 | 1.2″ | 200 | M35.5xP0.5 | <0.01 % | C |

|

MFA121-U50 | 50 | 4.0-16 | 1.2″ | 300 | M35.5xP0.5 | <0.05 % | C |

|

MFA121-U70 | 70 | 4.0-16 | 1.2″ | 300 | M35.5xP0.5 | <0.06 % | C |

|

MFA121-U75 | 75 | 4.0-16 | 1.2″ | 285 | M35.5xP0.5 | <0.14 % | C |

What Are Different Reading Requirements and How to Solve Them?

We all know that OCR comes with different reading requirements for effective working. If you use it for the automotive industry, the reading requirements will depend on the production method used.

Knowing these reading requirements can help you develop a precise plan before implementing the OCR process.

In the automotive industry, OCR technology is implemented in many different ways. Moreover, it is often divided into different production levels.

– Print OCR: The easiest method is to print OCR on a sticker and stick it to the specific part.

– Steel Belt Punching: Some companies use a steel belt to punch the OCR onto the product.

– Laser Engraving: It is the most advanced method many companies use today.

OCR printing is a traditional and time-consuming method. Besides, printed stickers have additional drawbacks. They are replaceable and, thus, prone to fall off during production. They cannot stay on the automotive parts permanently. Thus, automotive manufacturers use either a second or third method.

However, considering the growing demand, the automobile industry is gradually transitioning from steel belt punching to laser engraving. Also, it is challenging to modify the sequence-based production of steel belt punching. Thus, laser engraving is the most suitable method in today’s scenario.

Problem: Protective Layer Affecting the Recognition Accuracy

Even though it is a flexible method, the problem with laser engraving still exists. Automotive products need a protective layer to withstand exposure to gas and high temperatures.

The protective layer’s thickness can cause low recognition accuracy. It can also cause challenges in reading the OCR. For example, the surface’s grooves may affect performance by interfering with an accurate reading.

Solution: Use the Right Equipment

Even if low recognition accuracy is a significant problem, automotive manufacturers can still resolve it using a specific wavelength or light source angle.

In this case, circular lenses may not be appropriate since sources involve angles. Instead, an FA lens would offer the best results and be an excellent choice in such a scenario.

The OCR application in the automotive industry demands recognition accuracy. Thus, features like high-resolution and FoV have minor importance.

As a result, automotive manufacturers should opt for high-end cameras and FA lenses to increase contrast. This combo will ultimately improve recognition accuracy.

In short, creating a better contrast is the ultimate need of OCR in the automotive industry. The lens’ sharpness, i.e., the resolving power, offers better contrast required for recognition accuracy. All lenses in the FA121 series feature excellent resolving power, making them suitable for OCR applications.

Final Thoughts!

So, that’s all about optical character recognition technology used in the automobile industry. The idea behind OCR is simple. However, it can be challenging to implement this technology because of issues like the wide diversity of fonts. When an OCR camera equipped with a suitable lens is strategically positioned, it can replace labor-intensive manual processes, boosting efficiency and reducing risks.

The OCR technology has been widely used in the automobile sector, especially during battery formation. It helps read the text written on battery packs.

If you want to implement OCR at your company, make sure you use high-quality lenses. Our FA Lenses have led to a revolution in the manufacturing industry. VicoImaging, a technological leader in vision solution providers, is always developing better FA lenses for use in manufacturing. Our lenses have been refined and modernized throughout the years to accommodate optical character recognition applications.

Try our FA lens for OCR application, which features a 1.2-inch size and 75mm focal length. This unique combination allows it to support high resolution and longer working distances.

If you need assistance determining which lens from our FA lens series best suits your application, our team is in a prime position to provide that assistance. You can reach out to VicoImaging anytime to learn more about our FA lenses and services.