In our first sneak peek, VICO Imaging highlighted innovative machine vision solutions for robotic arms and automated sorting applications. We showcased our COOLENS® MFA121 and WWT series for robotic arm application, demonstrating their precision and reliability in demanding environments. Besides, our 360° series lenses were featured in an automated sorting vision system, showcasing their ability to capture high-quality images from all angles. Overall, our first sneak peek offered a glimpse into our commitment to providing cutting-edge machine vision technology for a variety of industries.

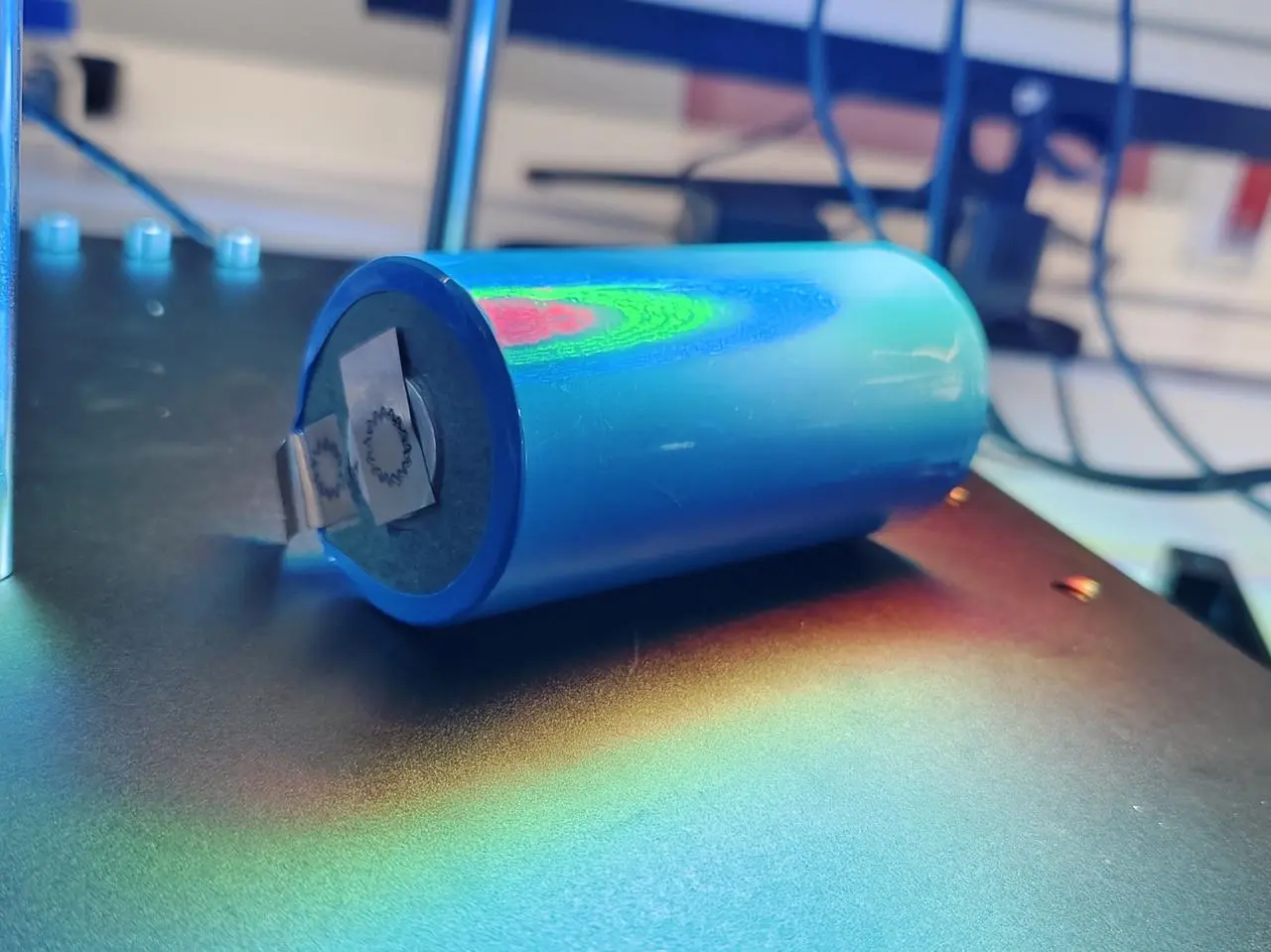

For our second sneak peek at Vision Stuttgart 2024, we will present our machine vision application in li-ion battery inspection featuring COOLENS® DTCM series bi-telecentric lenses. Additionally, there will be a PCBA imaging system demonstration featuring our DTCA 3D AOI lenses. In this article, we will introduce the solutions for both li-ion battery and PCBA inspections in detail.

Read related post> Revolutionizing Machine Vision with COOLENS® Lenses

Part One – COOLENS® DTCM Matrix Bi-Telecentric Lenses in Li-ion Battery Inspection

Overview

The lithium-ion battery industry is booming, thanks to the rapid growth of markets such as new-energy vehicles, portable electronic devices, and energy storage systems, as well as continuous technological innovation, rapid expansion of production capacity, and improving industrial chains, to become an important supporting force for global energy transformation and sustainable development. At the same time, with the high energy density, long cycle life, fast charging, and safety performance requirements, lithium battery companies are increasing R&D investment, driving continuous improvement in materials, techniques, and battery management systems.

In the production of lithium batteries, problems at any step may lead to various defects, thus affecting the batteries’ quality. Therefore, automated optical inspection (AOI) plays a crucial role. It uses high-precision optical imaging technology and advanced image processing algorithms to inspect various stages of lithium battery production, such as dimension measurement, cosmetic inspection, alignment inspection, and code reading, to ensure that the quality and performance of the battery meet strict standards.

Difficulties

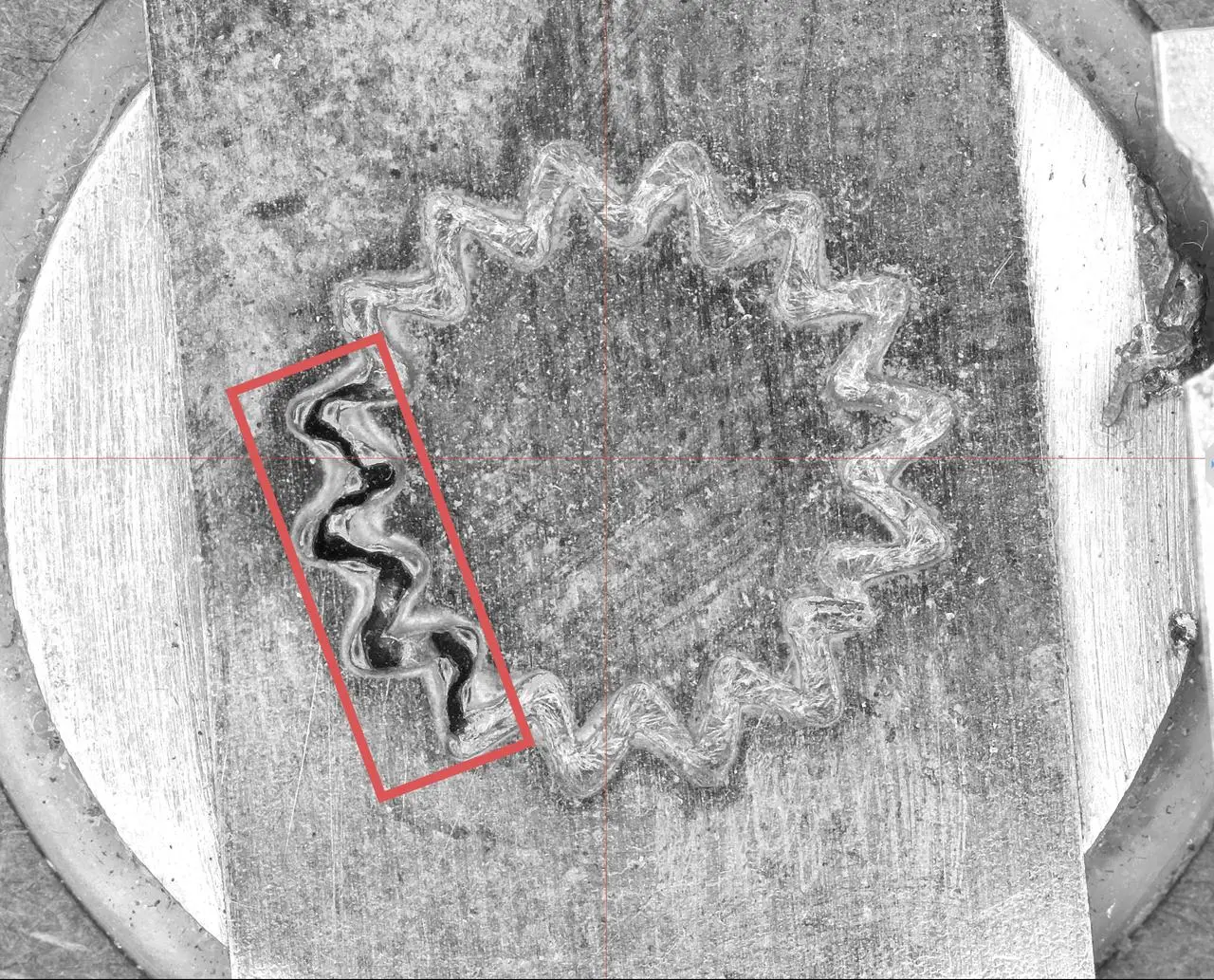

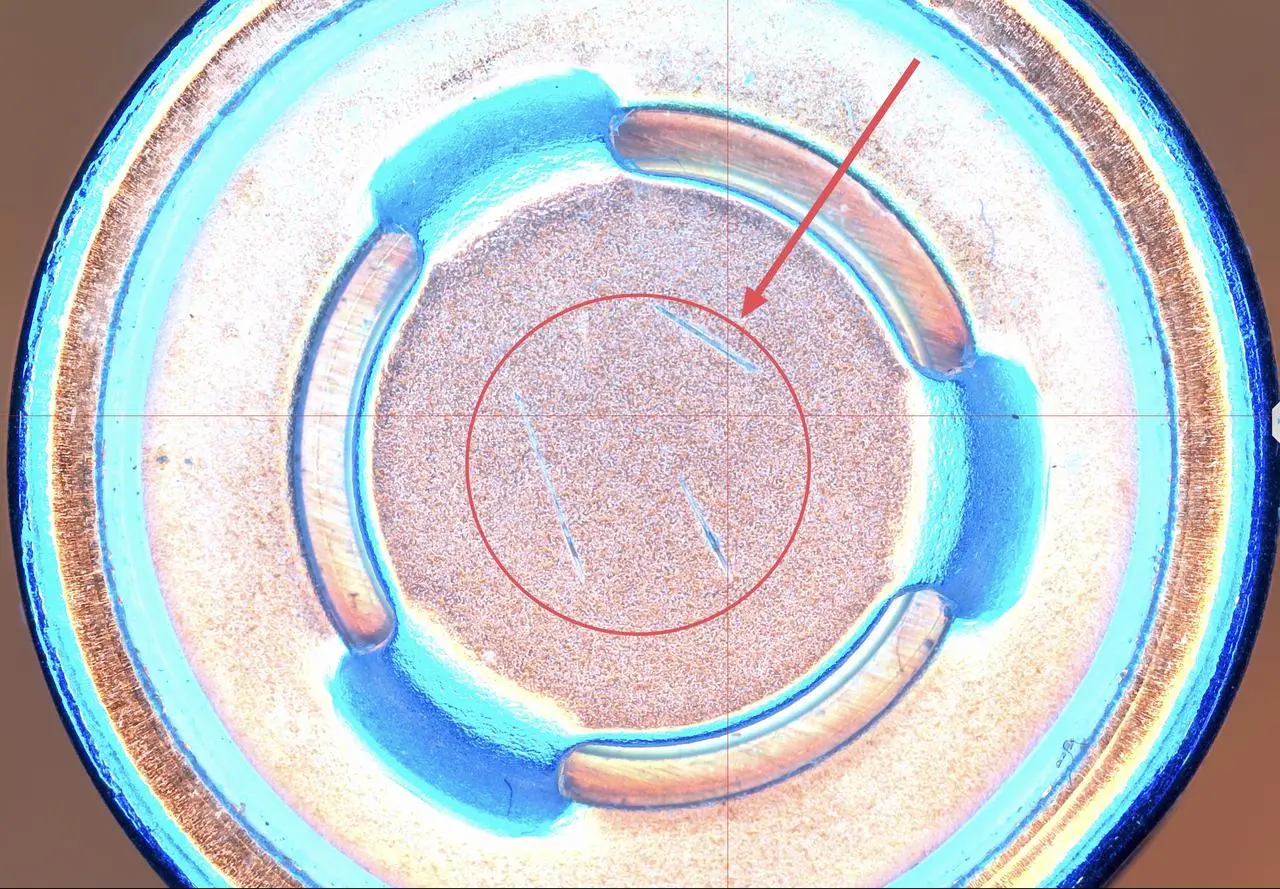

Various types of defects could occur once the welding process is finished. The defects were originally detected manually on-site. The inspected areas include the welding area and the inner ring of sealing pins. Small welding spots are very easy to ignore, and the defect shapes are diverse, difficult for FA lenses to define their shape edges. Some small defects are mixed in the black background and are difficult to distinguish. The inspection is time-consuming and labor-intensive. With COOLENS® DTCM matrix bi-telecentric lenses, such small defects can be quickly and accurately identified to meet customers’ needs.

Solution

Description of inspected objects and background:

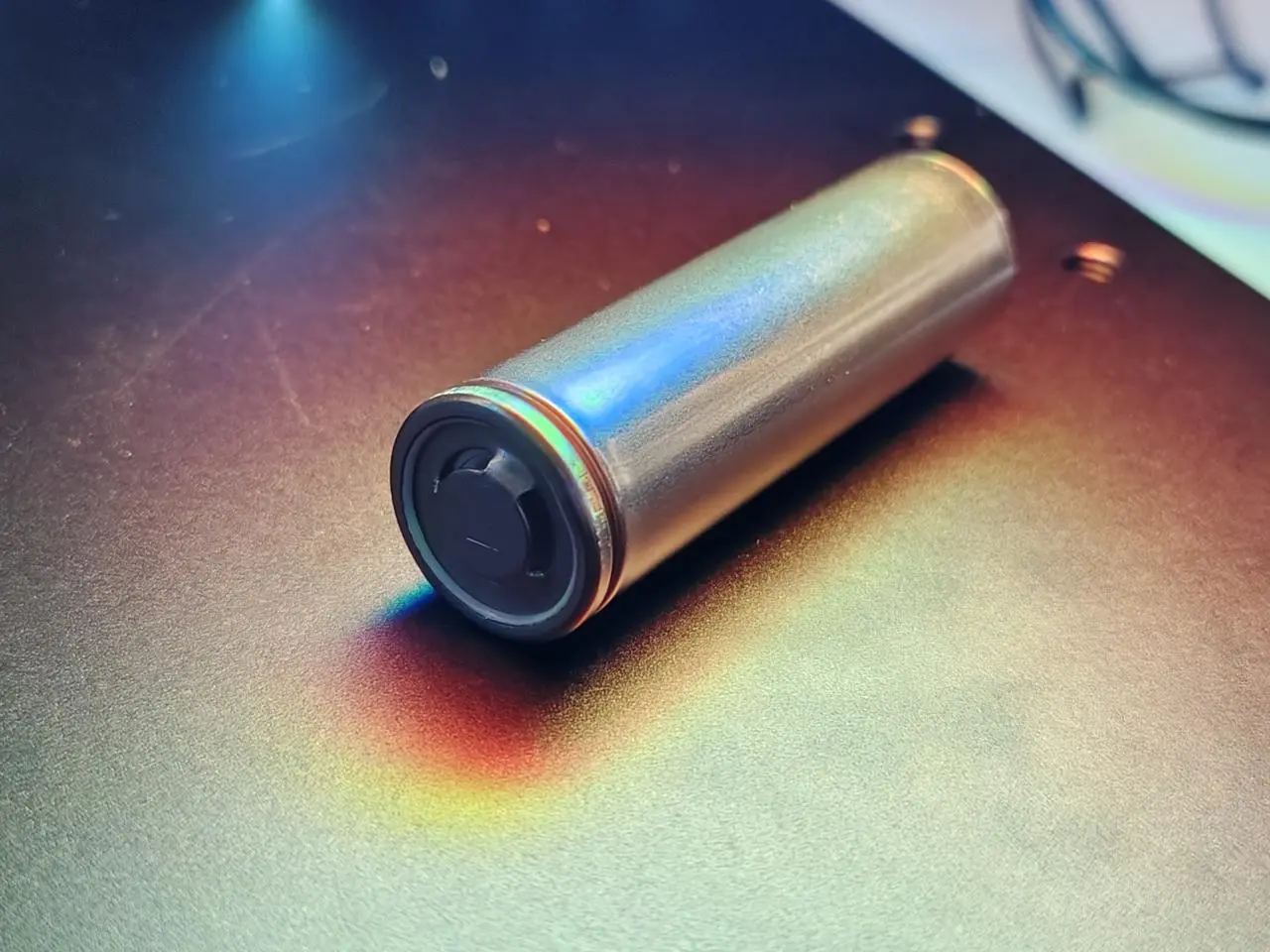

Inspection background: A lithium battery weld inspection is conducted. The defects on the batteries are tiny. The battery is made of metal, so it reflects light.

Inspection method: Still shooting.

Inspection requirements: Capture the defects on the surface of the lithium battery.

Hardware solution: DTCM bi-telecentric series with ring light.

Parameters: 240mm working distance and 0.3X magnification.

Inspection results

Inspection result: As shown in the pictures above, incomplete-filled grooves and scratches are clear and easily recognized.

Reasons for choosing the DTCM series to inspect li-ion batteries:

-

-

The high resolution of up to 151MP enables the inspection system to accurately locate defective areas and capture subtle defects on the surface of li-ion batteries, which is crucial to ensuring battery quality and improving the accuracy and reliability of inspection.

-

Its high uniformity ensures the consistent clarity and contrast of the image in different areas.

-

The large FOV of 26mm-300mm can cover a larger area in one shot, fully capture the product’s details, reduce the number of scans and movements, significantly shorten inspection time, and improve efficiency

-

With a modular matrix manufacturing process, it offers up to 238 front and rear end combinations while maintaining excellent product quality and uniformity.

-

It supports up to 67.6mm sensors

-

The lens quality is strictly controlled, which can ensure the consistency of its parameters.

-

In addition, our DTCM series also has the advantages of extremely low distortion and no parallax. Overall, it can improve the accuracy and efficiency of defect inspection and help ensure the quality of li-ion batteries.

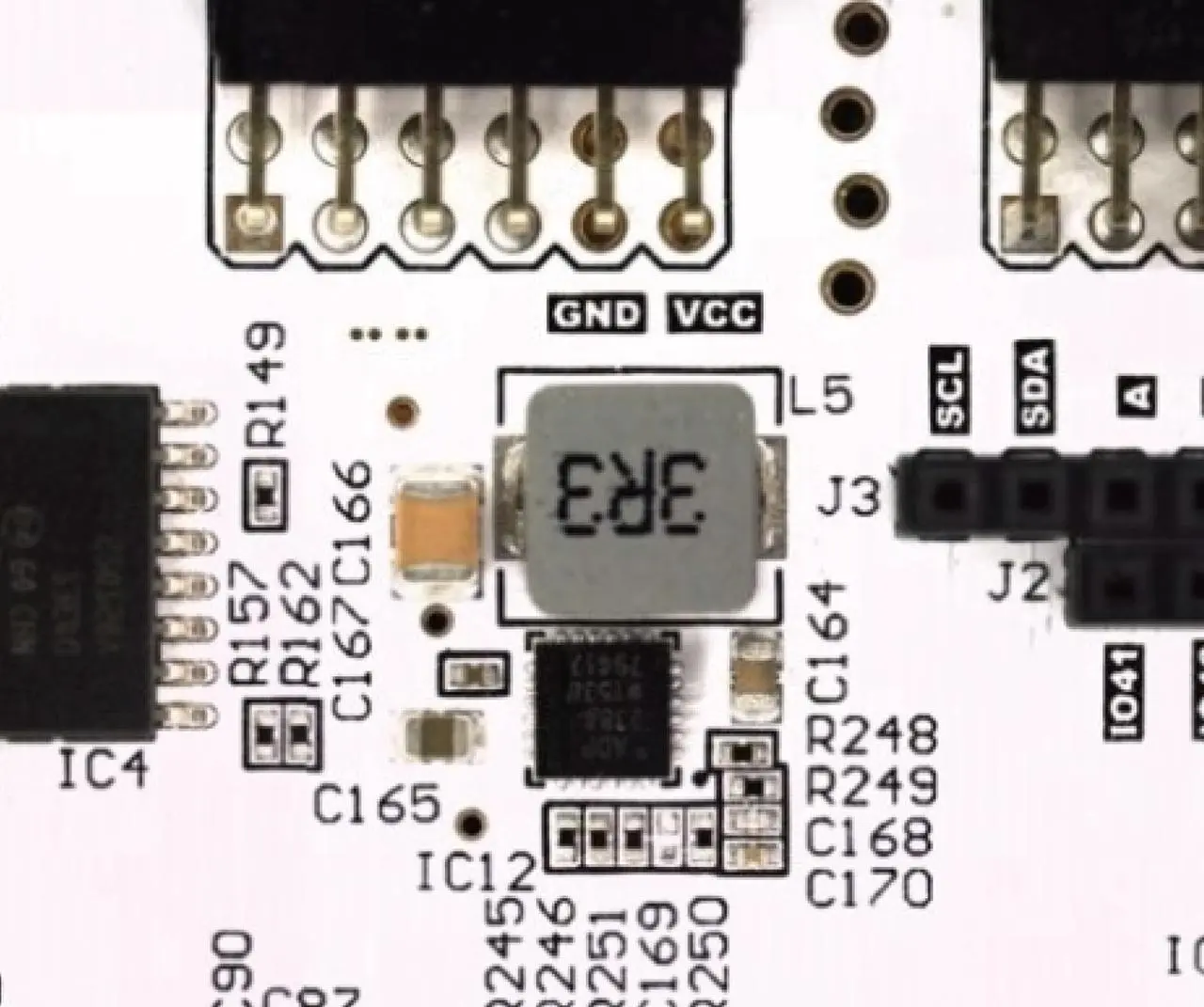

Part Two – COOLENS® DTCA 3D AOI Lenses in PCBA Inspection

Overview

With the miniaturization of SMT (surface mount technology) components and the high density of components on PCB boards, traditional visual inspection and random inspection face huge challenges, and the importance of 100% automated optical inspection is becoming increasingly prominent. AOI is a necessary node for digital management of the entire production process and centralized data collection.

For the limited three-dimensional structure composed of components, solder, and PCB boards on PCBA, PCBA-AOI can be divided into three types: 2D-AOI, 3D-AOI, and SPI (Solder Paste Inspection). The 2D-AOI optical path uses different colors of light at different angles to realize the collection of 3D information using 2D imaging technology and uses color to reflect the Z-axis information. 3D-AOI mainly uses the phase shift method to capture a series of phase-shift modulated grating images projected onto the object measured and decoded to obtain the complete three-dimensional image information of the object. This method can produce high-resolution and high-precision images, enable reliable 3D measurement, and cover a large area.

Read related post> Understanding the Role of AOI Lens in Ensuring Flawless SMT and SMD Production

Difficulties

During inspection, FA lenses may cause edge distortion in images when the field of view is too wide, leading to shape and size distortion of objects. Especially when tall objects are in the center of the field of view, the distortion is more obvious. In addition, FA lenses have difficulty coping with the height discrepancy of the measured objects, leading to inconsistent imaging sizes and affecting inspection accuracy. When splicing large-size PCBs, FA lenses often have edge distortion problems, affecting the overall image effect. At the same time, traditional telecentric lenses have poor chromatic aberration performance during color imaging due to the small amount of incident light. Our COOLENS® DTCA 3D AOI series has a apochromatic and a high double telecentric design, which performs well in chromatic aberration minimization and distortion control and provides the most accurate data.

Solution

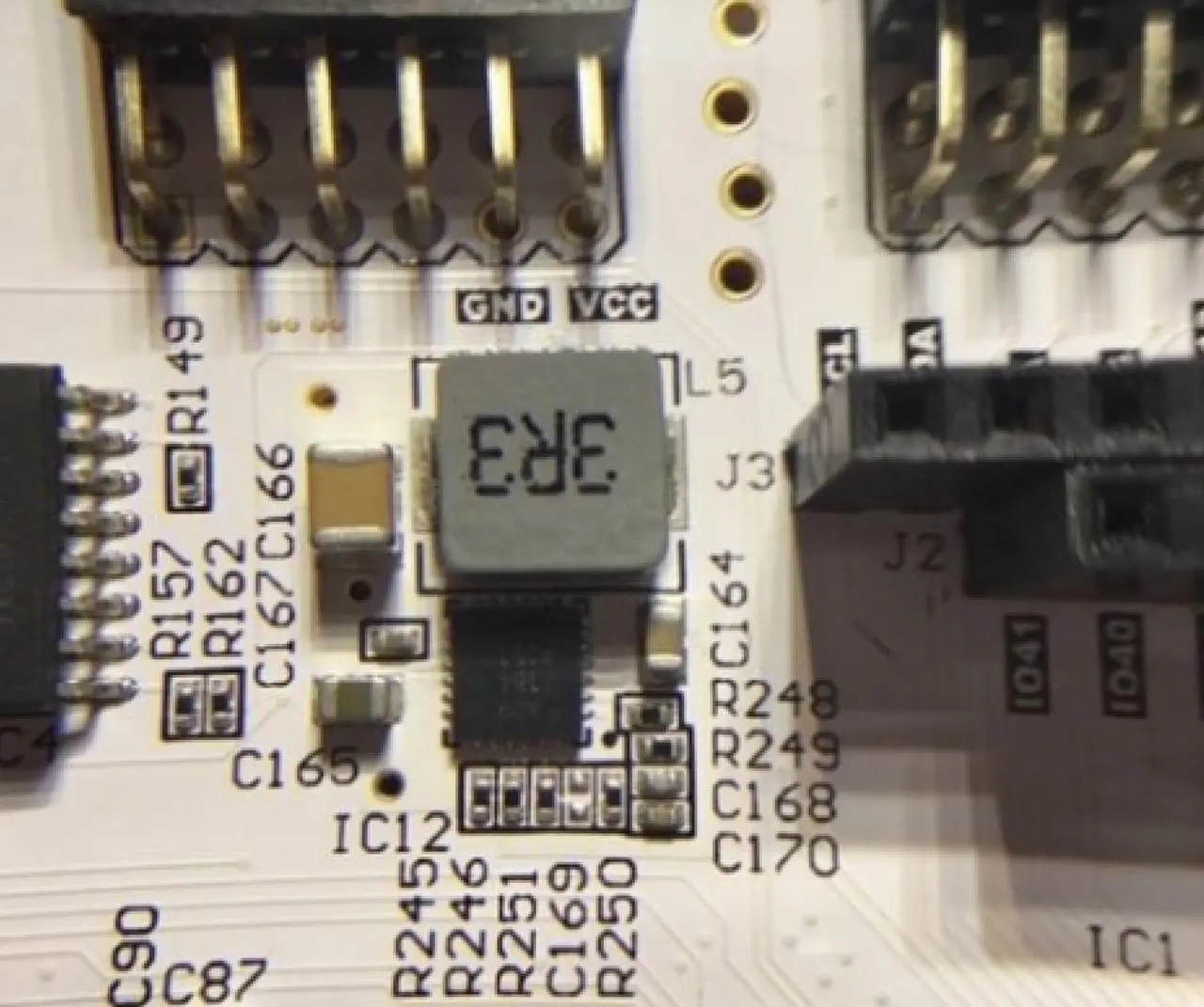

Inspection background: PCBA is inspected and the package size of its components is very small, with a three-dimensional structure and height difference.

Inspection method: Still shooting

Inspection requirements: High imaging consistency within a single FOV, consistent clarity, brightness, and color aberration between the edge and the center, no shadows, no distortion, and high resolution.

Hardware solution: DTCA 3D AOI series

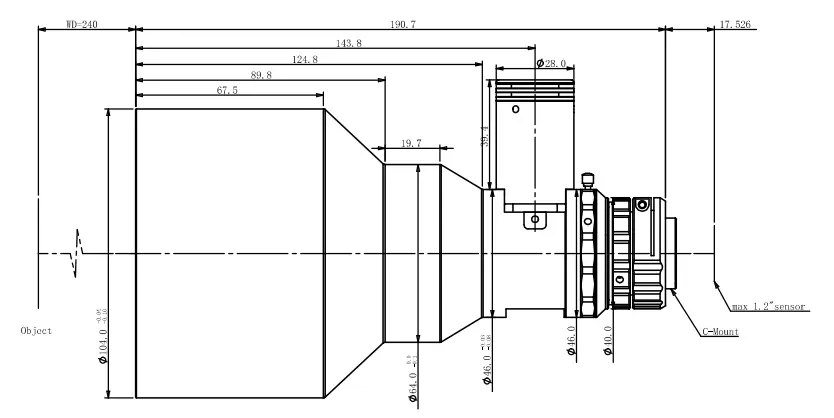

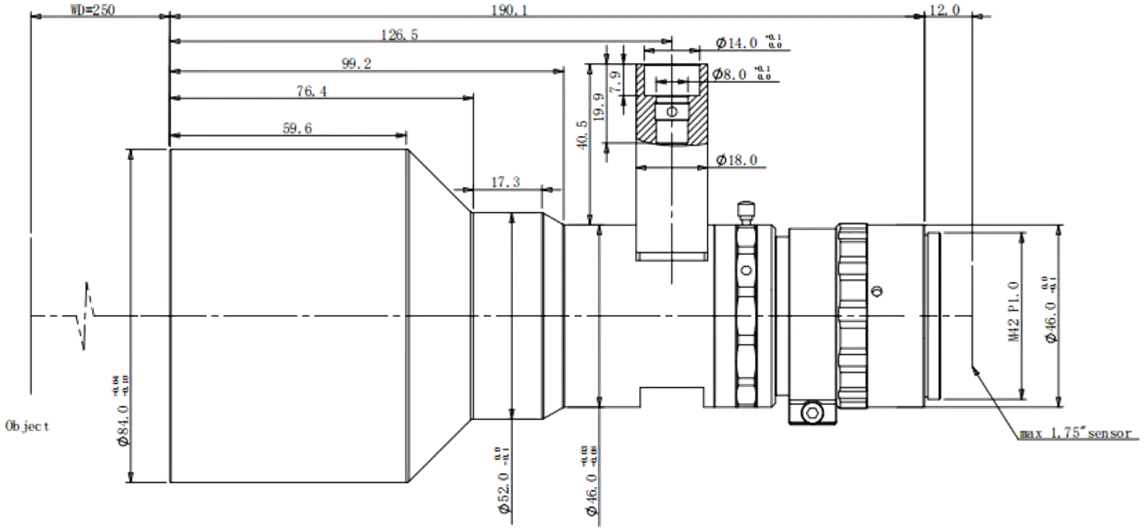

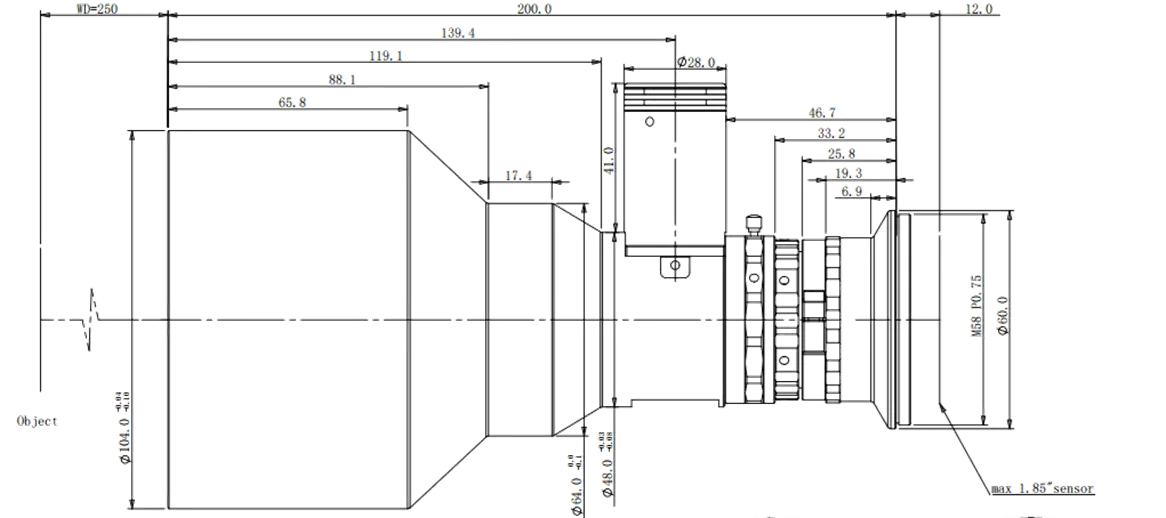

Parameters: Matching 1.2″, 1.75″ and 1.85″ sensors, and working distances of 150mm to 250mm.

Inspection result: Compared to FA lenses, our AOI lenses have clear imaging without shadow or distortion. Besides, it ensures high imaging consistency, which means highly consistent brightness, color aberration, and clarity at the edge and center.

Reasons for choosing DTCA 3D AOI series for PCBA inspection:

-

Shadow-free and low distortion.

-

It is exclusively designed for 3D AOI in the PCB/PCBA industry.

-

It perfectly matches the industry’s commonly used 1.2″, 1.75″ and 1.85″ sensors.

-

It offers the industry’s ideal working distance options, with 150mm to 250mm working distances.

- apochromatic and high double telecentric designs ensure data accuracy.

Conclusion

This blog shares two highlights of high-precision visual inspections for Vision Stuttgart 2024, fully demonstrating the outstanding performance of COOLENS® series lenses in solving industrial inspection problems.

First, for defect inspection in lithium battery welding, COOLENS® DTCM matrix bi-telecentric lenses, with its unique bi-telecentric design, achieve rapid and accurate identification of tiny weld defects, effectively solving the problem that FA lenses are difficult to define the edges of defect shapes under complex backgrounds. This solution not only improves inspection efficiency but also ensures the reliability of the inspection results, meeting the strict requirements of the industrial field for high-quality inspection standards.

Secondly, in the field of PCBA inspection, COOLENS® DTCA 3D AOI series overcomes the challenges of edge distortion of the field of view and inconsistent imaging size caused by height differences through its RGB confocal design and other technical optimizations. These advantages ensure the accuracy of the inspection data and provide strong technical support for the quality control of precision electronic products such as PCBA.

In summary, the COOLENS® series has demonstrated exceptional results in lithium battery weld defects and PCBA inspections with their excellent performance and precise inspection. The application of these technologies promotes the advancement of industrial inspection.

VICO Imaging at Vision Stuttgart 2024

As we wrap up our sneak peek into what VICO Imaging has planned for Vision Stuttgart 2024, it’s clear that we’re not just participating in the event; we’re excited to be one of its highlights. Our cutting-edge products lead the way in machine vision, promising a bright and innovative future. If you’re heading to Stuttgart, we’d love for you to visit our booth (8A52) and see the future of machine vision technology up close. For a deeper dive, please feel free to contact our sales engineers (sales@vicoimaging.com). We can’t wait to share our vision with you!