Overview

Cylindrical li-ion batteries (LIBs) are a widely used energy storage solution, and their cylindrical shape enables them to perform excellently in applications ranging from consumer electronics to electric vehicles. Notably, the latest 4680 battery, with its larger diameter and longer cylindrical design, is expected to enhance energy density, range, and overall performance. As market trends prefer more efficient, high-capacity, and durable batteries, cylindrical LIBs are favored for their superior energy density, extended lifespan, and high discharge rates. Inspecting the shells of these batteries is crucial to ensuring their safety and performance, given the critical role they play in modern technology. Rigorous inspections help identify defects in the shell, such as cracks or corrosion, which can effectively prevent potential failures and ensure reliable operation. This reduces the malfunctioning risks.

Defect types

Scratches and dents: Elongated grooves or scratches that appear on the surface of a battery shell are typically caused by physical friction or impacts. Dent refers to a local depression on the surface of the battery shell. This defect may be caused by an external impact or an uneven cooling process. Scratches and dents may weaken the structural strength of the battery case, making it more prone to deformation or cracking when exposed to external forces. This may result in exposure of internal battery components, increasing the risk of short circuits, leaks, or other safety hazards.

Rust and dirt: Rust and dirt may cause the material properties of the battery shell to deteriorate, such as reduced strength or increased corrosion, which in turn affects the overall performance of the battery. Dirt not only affects the appearance of the battery, but it can also mask other potential defects, making inspection more difficult.

Contaminants or foreign objects: A variety of visible contaminants may exist, such as oil that may have adhered to the battery during manufacturing, transportation, or storage. There may also be foreign objects on the battery shell, such as debris or metal particles, which may interfere with the normal operation of the battery. These foreign objects may cause local overheating or other safety issues, thereby increasing the risk of battery use.

The challenges

Cylindrical lithium-ion battery (LIB) shell inspection faces challenges that need to be addressed to ensure battery safety and performance. One of the main challenges is detecting microstructural defects within the shell, such as tiny cracks or localized corrosion, which may be difficult to identify with traditional inspection methods. This is because traditional inspection methods have the following constraints:

Curved surface: LIB curved surface may distort images or data collected by inspection tools. This curvature may result in incomplete or inaccurate reads, thus making it difficult to inspect distorted defects. Therefore, using multiple lenses to image the inner wall from five different angles is a waste of space, and the light cannot evenly cover the entire surface.

Surface reflection: The inner wall surface of the battery shell reflects light, and the strong light covers the defects, altogether making it difficult to spot the defects with FA lenses.

Complexity of defect types: Minor cracks and localized corrosion may have different appearances and coatings, requiring different inspection methods. Traditional methods may not be flexible enough to adapt to the various forms of these defects, making the inspection more complicated.

Even subtle deviations may significantly affect battery performance and safety. It is critical to ensure that inspection techniques can accurately and effectively identify potential problems without causing damage. These challenges require more advanced non-destructive inspection methods to increase inspection reliability and maintain the high standards for cylindrical LIBs.

The solution

Inspection configuration:

Cameras: 500W 3.45µm 2/3″, monochrome camera and color camera

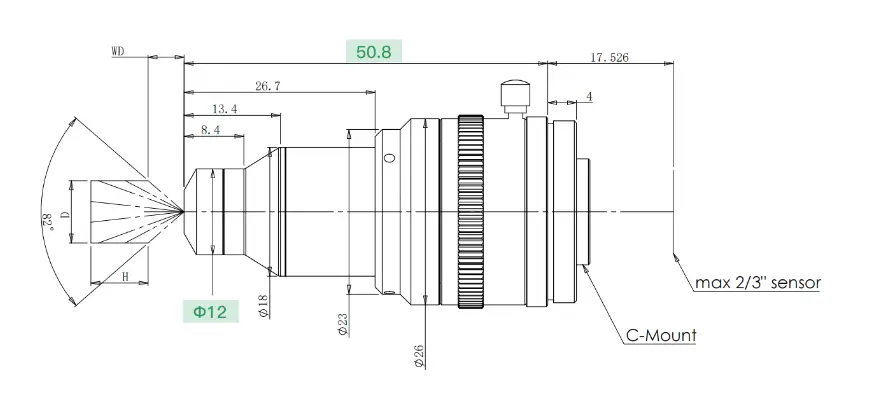

Lens: PRHI230-82

Light source: SQ9-RL26030-B

Cylinder’s inner diameter: 46mm

Cylinder height: 94mm

Inspection solution:

- Side wall inspection

The difficulty of side wall inspection lies in lighting. Since the light entering from the middle of the product sidewall will cause severe reflection, the middle area cannot be too bright. Therefore, a large-diameter and low-angle ring light is used with the light source height higher than the lens and the working distance between 70mm and 85mm. At the same time, a 500W 3.45µm 2/3″ camera is used to identify whether there is rust or dirt.

- Bottom inspection

Defects on the bottom plane need to be inspected using a lens with fixed magnification from 0.1x-0.13x and a 2/3″ camera. Open surface light can be used for lighting since the light ray of the area light is more uniform and close to the effect of shadowless light. Therefore, there will be no local highlights. If a black-and-white camera is used, it is recommended to use a blue open area light so that the contrast is the largest.

The results and benefits

As is shown in the pictures above, when shooting with a monochrome camera, the oil stains are more obvious, while the rust is more obvious with a color camera. The following explains why we chose the 360° view lens series for the inner wall inspection of cylindrical LIB:

Simultaneous imaging: The 360° view lenses can inspect the side wall and bottom of the cylindrical battery shell simultaneously to ensure the entire area is covered. It helps find potential defects or unevenness. Compared with the single-angle inspection, the lens can obtain an image of the entire inner wall in one shot, reducing the time wasted due to multiple-angle inspections, thereby improving inspection efficiency.

High resolution: With high resolution, this series produces high-precision images that can help accurately identify tiny defects on the inner wall, such as scratches and cracks. This is crucial to ensuring the quality of batteries.

Compact design: The inner wall inspection of the cylindrical lithium battery shell needs to be carried out in a relatively limited space. It is easy to probe into the inner shell using the compact lens, and comprehensive inspection can be conducted even in space-constrained conditions. In addition, because it is tiny, the lens can be flexibly configured in complex or narrow production environments, allowing the inspection equipment to adapt to batteries of different sizes or shapes. For situations where portable inspection equipment is required, the lens is very easy to carry and reconfigure. This design greatly improves the flexibility of inspection and operation.

Conclusion

The 360° view lenses can provide all-round and high-precision inspection within a limited space due to their small and compact design and the properties of simultaneous imaging of the inner wall and bottom. Therefore, the compact design saves space and increases flexibility and compatibility. Besides, using the lens reduces imaging times, installation and maintenance costs and improves accuracy. Through comprehensive imaging, the 360° series lens effectively improves the inspection efficiency in the lithium battery production process and enhances the reliability of battery products.