Miniaturization is an unrelenting trend in the 3C industry – computers, communications, and consumer electronics. Devices get slimmer and lighter with each generation. This creates a dilemma for manufacturers – components shrink to tiny sizes, but need even more rigorous tracking and quality control.

Solving this problem led to the rise of microscopic and invisible barcodes on 3C parts.

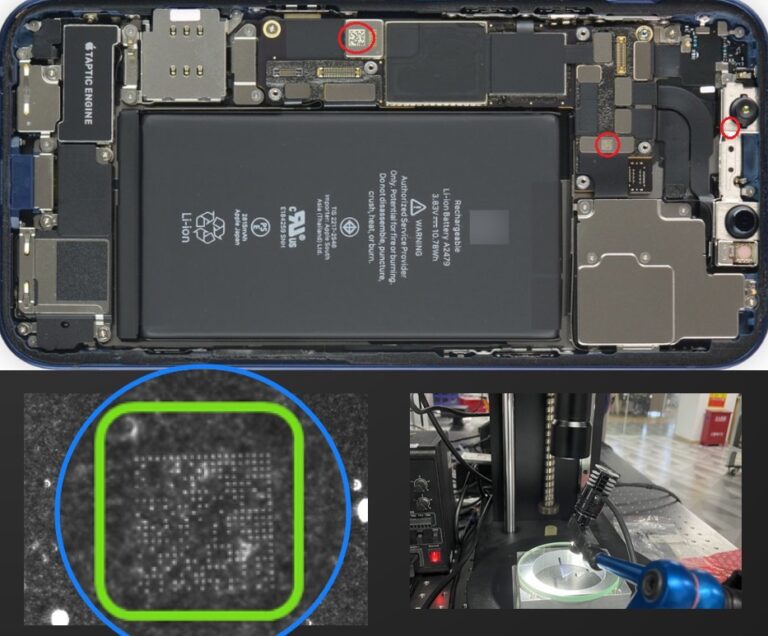

As 3C products slim down, components like chips, sensors, and displays are only getting smaller. A smartphone contains over 1,500 miniature parts in a compact chassis. Each part must be followed from production to assembly to catch defects early. Barcodes help track components across distributed global supply chains.

But barcodes need significant surface area to work.

How can miniscule parts accommodate IDs? This challenge fueled the development of tiny barcodes that are microscopic or even invisible to the human eye.

The Challenges of Reading Invisible Mini Barcodes

Microscopic barcodes work by squeezing the code into a tiny fraction of a part’s surface. But these are too small for standard barcode scanners to read reliably.

Most scanners have a built-in decoder and single lighting system with 3-10X magnification – insufficient to image micro barcodes.

Industrial-grade equipment is needed to successfully read and inspect small barcodes.

Key requirements include:

- High resolution cameras: Over 1” sensors camera for large FOV needed to capture microscopic details.

- Telecentric lenses: Micro barcodes demand at least 20MP lenses for high resolution cameras.

- Ring lights: To evenly illuminate tiny codes, specialized ring lights in blue or white are essential.

- Software: Advanced algorithms precisely locate and decode low contrast micro barcodes.

As components shrink but inspection areas grow, these specs become baseline requirements. This poses a stiff challenge for manufacturers to upgrade barcode reading gear.

Matching Top-Notch Optics to Emerging Camera Trends

Camera sensor resolution and size are critical for micro barcode scanning. Over 20 MP and 1″ sensors can image at the requisite micro level. This demands lenses engineered for large image circles and sensors.

VICO Imaging offers various imaging solutions for microscopic barcodes based on specific requirements for each project. Their lineup has over 125 options to fulfill diverse industrial imaging needs:

– Magnifications from 0.37X to 2X or higher

– Sensor coverage from 1/2.5” to 1.1”

– Top-tier quality with consistent performance and durability

With over 50,000 lenses under such series delivered to customers worldwide, VICO Imaging has the most comprehensive range of micro barcode reading optics. Their aberration-corrected macro lenses render sharp, high-contrast images across the entire field of view. This ensures reliable micro barcode decoding.

Their optics also equip inspection systems across electronics, pharmaceutical, and automotive sectors.

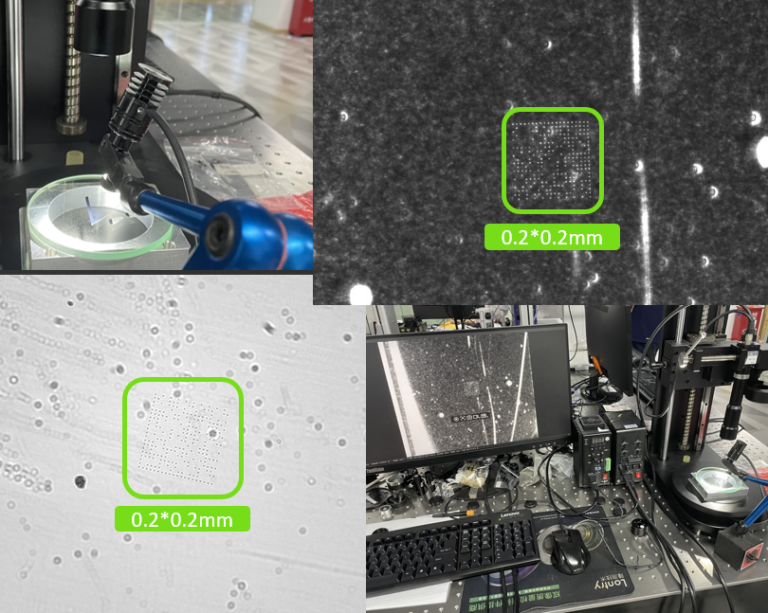

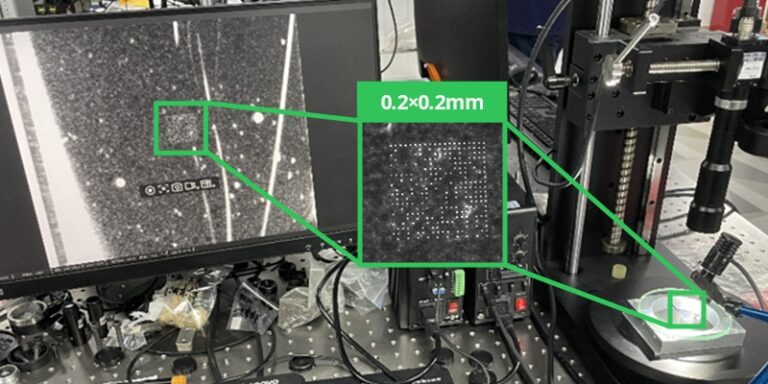

Revolutionizing Micro 2D Code Recognition on Transparent Mobile Screens - A VICO Success Story

Not long ago, we found ourselves facing a fascinating project challenge. A globally renowned mobile phone brand approached us with a unique predicament. They needed a solution to detect micro 2D codes laser-engraved on the transparent glass screens of their smartphones. They had scoured the machine vision industry for solutions, but none could accurately detect these codes. But as they say, when the going gets tough, the tough get going! And that’s exactly what our engineers did. We rose to the challenge and, in the end, we delivered.

One of our lab-proposed solutions included a one-inch or larger camera due to the need for high resolution paired with a relatively large field of view. We suggested using a 20-megapixel camera paired with VICO’s WWK20 series. And as for the light source? We recommended either blue or white ring light.

This is just one example of how we’re pushing the boundaries in the field of machine vision. If you have any requirements for micro barcode reading or recognition visual solutions, feel free to get in touch with our sales engineers. We’ll listen to your specific needs and tailor the perfect visual solution just for you. After all, at VICO Imaging, we believe in solutions that fit like a glove – perfectly designed for your unique needs.

Conclusion

Microscopic barcodes enable granular tracking of ever-shrinking 3C components. But reading these tiny codes requires upgrading from conventional barcode scanners to industrial imaging solutions.

With cameras moving to higher resolution sensors, the right optics become imperative. VICO Imaging’s lenses provide unrivaled imaging performance for scaled-down barcodes. Their extensive selection empowers systems to leverage the latest camera technology.

As 3C products pursue extreme miniaturization, microscopic barcodes present complex imaging challenges. With our lenses at the core, manufacturers can build reliable inspection systems to keep pace with component scaling. Tiny parts can get smaller, but their tracking remains ironclad.