The laptop industry has seen a sales boom during the pandemic era. To fulfill this boosted demand, the manufacturing process of laptops needs to be monitored as quickly as the time demands.

The laptop industry has seen a sales boom during the pandemic era. To fulfill this boosted demand, the manufacturing process of laptops needs to be monitored as quickly as the time demands.

If there happen to be product defects during the process of laptops, it affects the quality. The process requires more time for quality checking. The manual inspection of the laptop takes a lot of time and it’s a high-cost process.

Therefore, there is a need for production efficiency for each step to make a finished product defect-free. For that purpose, telecentric lenses are there to help with each step. It inspects the product, identifies the faults, takes measurements, and positions the product accurately.

Let’s explore how telecentric lenses can help the laptop industry and how it has enhanced their production efficiency using intelligence.

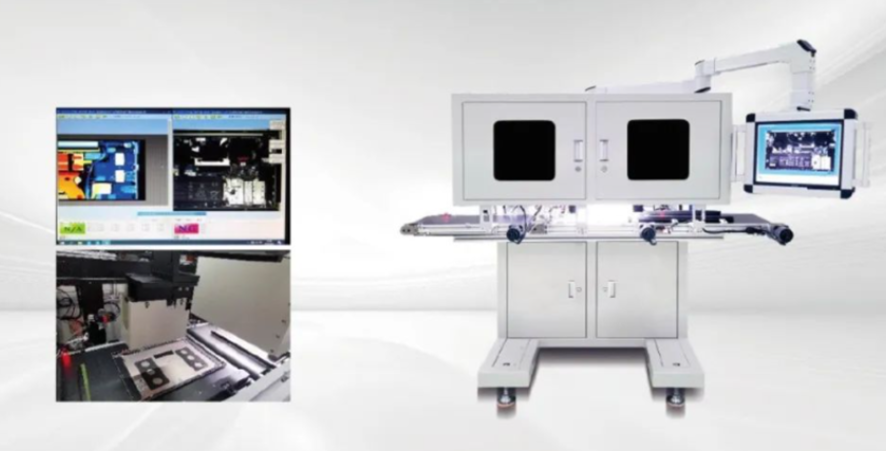

Scenario Application in the Laptop Industry

Laptop A/C/D Housing Inspection

The intelligent inspection enables laptop defects to be found easily. Through housing inspection, it is possible to detect the presence or absence of the following:

- Auxiliary materials

- Mixed materials

- Misalignment

- Reading code

- LOGO

- Character silk screen fuzzy

- Broken line

- Integrity of the internal parts of the laptop

- Flatness,

- Height segment difference,

- Internal and external length and width dimensions, gap dimensions,

Also, the presence or absence of screws/auxiliary materials, missing/depth of LOGO, or missing/default of the height/degree of the hot melt column, and directional development are detected.

Laptop Internal Inspection

During an automated inspection in the laptop industry, internal inspection is really important. It inspects the following objects during the process:

- The internal parts of the laptop antenna

- Device omission

- Disassembly

- Mixed assembly: BTB omission, parts reversal, rubber sets (main and speakers, etc.)

- Omission (mylar, conductive cloth, shrapnel, copper presidents, foam, QR code, battery)

- Connector insertion is in place

- Auxiliary material omission / multi-paste / offset

- Screw floating high / dis-assembly

- Skew/omission

- Barcode / QR code reading

- Material number verification

- Battery compartment foreign objects

- Mixed materials

- Misalignment

- Logo and character silkscreen fuzzy

- Broken lines

- Whether there is an antenna and speaker in the card slot

- Over station binding

Barcode Scanning in Assembling Line

The barcode scanning through automated production not only saves your time but it reduces labor cost as well. It keeps the quality tracking like the traceability of the product is established in the record that passed through scanning. Therefore the data is easily synced with the software.

Automated inspection is useful in the following ways in the laptop industry:

- Bar code scanning

- 1D / 2D code size

- Binding over the station

- Connection to MES data upload function

Finished Product Inspection

After the product finishes, the function of telecentric lenses is to identify the accuracy rate and check if the product is as per the defined parameters.

The role of intelligent inspection equipment identifies if the keyboard gap, keyboard characters, keyboard height, keyboard reading code, and connect MES data upload function has the stated dimensions or not.

The following are the dimensions or parameters on which the laptop is inspected:

- Detection accuracy: 0.01mm

- Misjudgment rate: <0.2%, leakage rate: <0.1%

- Inspection size: up to 19-inch notebook

6 Advantages to Choose VICO Product

VICO provides its customers with machine vision, computer vision, and digital imaging technology to enhance productivity and exhibit efficiency in less time.

Why choose VICO products? We have compiled 6 different advantages of using VICO products which are explained as follows:

- VICO product (telecentric lenses) is suitable for online inspection in the assembly line as well as in simple operations. It provides good stability, fast inspection speed along with low maintenance costs.

- VICO’s telecentric lenses are used to provide high-precision measurement. Therefore, you can achieve dynamic repeatability accuracy of 0.015mm or less.

- Telecentric lenses give strong versatility and modular design that are easy to change and maintain. Also, they are simplified and can be deployed more quickly. That means vision solutions can be quickly set up and debugged, reducing on-site debugging time and personnel costs.

- Choosing a VICO product enables image display of inspection data and automatic identification of qualified or unqualified data. The continuous detection of defects helps to reduce the operating status and makes it more efficient. All the data is stored and all the results and other information are helpful to make reports. So, the data can be easily traceable. One key measurement is all that is needed to easily operate by production line staff and the real-time verification of data is made easy.

- Telecentric lenses allow vision algorithm modularization. With VICO’s product, it is easy for new products to be quickly modified and to adjust the algorithm. It makes the product’s compatibility stronger. So, you can achieve MES system cooperation and product AOI function.

- The last advantage of choosing the VICO product is that it provides a self-developed underlying software algorithm. It has a short development cycle. And fast and efficient compatibility with a variety of non-contact measurement scenarios, customizability, and scalability.

What Can We Achieve with Vico Telecentric Lenses?

VICO’s telecentric lenses can detect all sorts of defects and sort them out in no time. Laptop A/C/D shell inspection equipment can detect all kinds of point and line defects in the outermost layer of the protective material. It is 10 to 20 times higher than the traditional inspection method.

The product yield is as low as 99%. Laptop inside-out inspection equipment for notebook computers in the semi-finished assembly after the appearance of inspection can accurately capture the parts missing, wrong, mixed, auxiliary materials missing paste / multi-paste / offset, screws floating high/wrong installation / skewed /missed or defects.

Telecentric lenses can capture real-time screening of NG products. while a variety of defective data background statistics is used to improve production processes.

The product yields provide important information support. The finished product appearance inspection equipment for notebook computers can achieve a one-stop full inspection of finished products, front and back of a variety of defects, and intelligent interception of defective products for real-time alarm, reduce production waste, and effectively ensure the quality of products shipped.

Conclusion

The effective use of telecentric lenses in the laptop industry has proved to be much useful equipment. Whether to enhance productivity efficiently or to reduce cost, telecentric lenses have played their role widely in the laptop industry.

The demand for laptops will be increasing in the race with technological times, so the production of laptops should be intelligently processed to decrease defects and focus more on efficient production processes.