All lenses used in manufacturing fall under the umbrella term “industrial lenses”. It includes both fixed and variable magnification lenses and also telecentric lenses.

These lenses play a crucial role in the machine vision industry. They may directly impact how the system processes algorithms and images. Thus, we consider them a vital component of any ideal vision system.

From quality control and inspection to robots and automation, custom industrial lenses are integral to modern manufacturing processes.

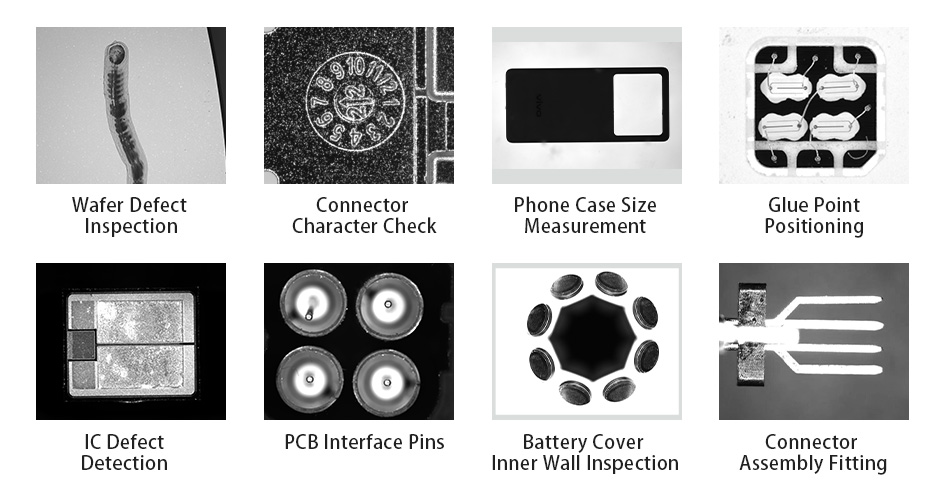

These lenses assist in finding scratches and damage on metals, glass, thin films, wafers, and other surface layers. Moreover, you can also use them in MARK point positioning, Surface Mount Technology (SMT) detection, and industrial microscopic vision alignment. Detection of Electronic parts, PCB lines, jack positions, and many more are all examples of the many applications of industrial lenses.

Even though numerous standard alternatives are available, we can customize industrial lenses for the best performance in certain situations.

Customizing these lenses includes determining the application’s needs, choosing the best lens type and material, and collaborating with a supplier to develop and test the final product.

A customized industrial lens can fulfill your actual needs. But very few people know the proper ways to customize lenses. Hence, this article is all about customizing industrial lenses to get the best out of them.

Let’s start!

What Are the Basic Requirements for Customizing Industrial Lenses?

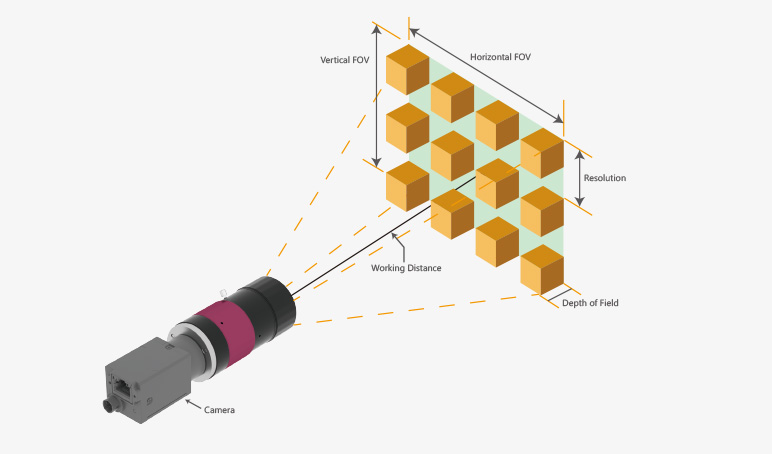

The first step in designing an industrial lens is determining what features you want to see in the lens. Considerations like the lens’ intended use, the object’s distance, the camera sensor, illumination, and the desired field of view are all part of this process.

Considering the object’s distance and CCD size of industrial cameras can also help you choose the best lens.

Once these parameters are established, a lens with the proper specifications and material can be customized to achieve the desired results.

Here is an example to choose a right lens:

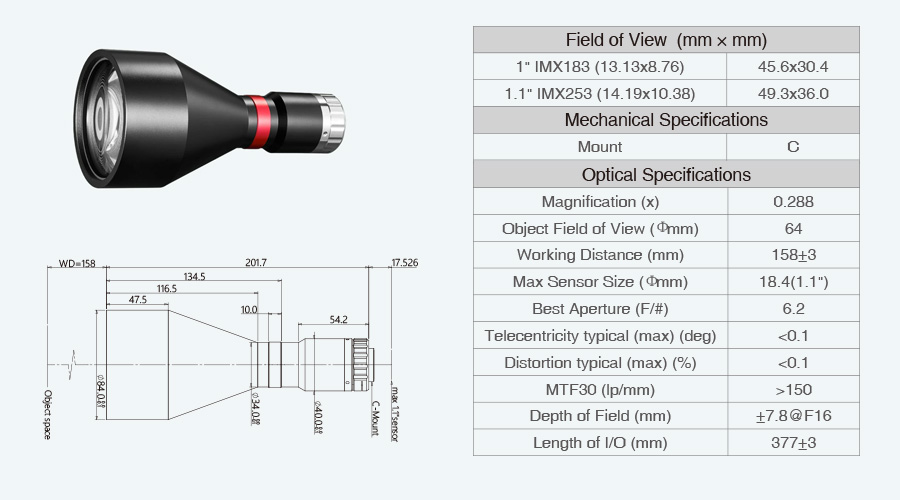

A user wants to choose the right telecentric lens for measurement detection application. Below are the known parameters:

– Field of view: 42*33mm

– Camera: 12MP CMOS

– Pixels size: 3.45um

– Sensor target surface size: 14.1mm*10.3mm

Then, which type of telecentric lens should the user choose?

Let’s say the user is not familiar with the lens model. So we must first calculate the magnification by using a standard formula.

Formula to calculate magnification:

1. Lens Magnification=sensor size(length)/image FOV(length)=sensor FOV(width)/image FOV(width)

2. sensor size(width)=sensor size resolution(width)*pixels size/1000=sensor size resolution(length)*pixels size/1000

Stepwise Procedure to Find Out the Right Lens

Step1: Calculating the lens magnification

First, calculate the required lens magnification in both length and width by using the above formula.

– The required lens magnification (in length)=14.1mm/42mm=0.335

– The required lens magnification (in width)=10.3mm/33mm=0.312

So we know the magnification we can choose is 0.312

Step 2: Calculating the camera CCD’s size

Let’s get into the Physics and apply the Pythagorean theorem. Here, we know the camera sensor diagonal is 18.4mm. Thus, the CCD should be 1.1 inch.

As a result, the user can choose the lens from COOLENS DTCM111 series.

You will notice many different models in this lens series. So, we must scroll down to see which lens model’s magnification is closer to 0.312. Make sure you choose the smaller magnification value since it helps ensure the lens has enough FOV to cover the object to be measured.

From the above chart, we can conclude 0.288 is the right one to choose.

So in this case, we can recommend the user to choose the DTCM111-64H-AL telecentric lens.

How to Determine Which Lens Type Is Best for Your Application?

Many different types of industrial lenses are available in the market, making the selection process difficult. However, you must choose the best lens type based on your specific application.

You don’t have to go for the most expensive lens. Instead, you can choose the best and most suitable lens according to the application needs.

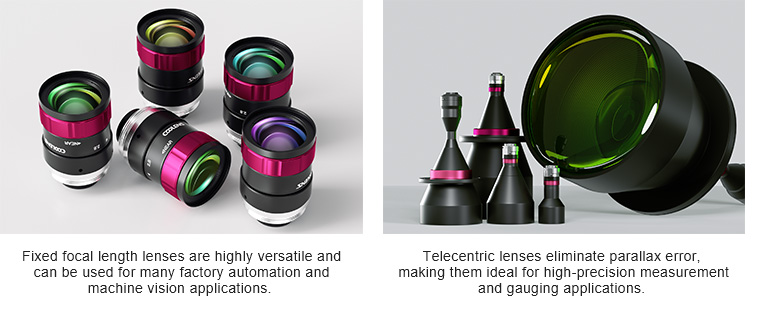

Several varieties of industrial lenses exist, each with its own set of benefits and drawbacks. Numerous lenses, including those with fixed focal lengths, zoom capabilities, telecentric focusing, and low distortion, have widespread manufacturing usage.

The simplest and cheapest choice is a fixed-focal-length lens, whereas zoom lenses provide more control over the field of view. They vary in the length of their focal points.

A typical zoom lens will cover focal lengths from 50 to 200 millimeters. Telecentric lenses are the way to go for tasks that need pinpoint accuracy. However, telecentric lenses can be a little more costly and bulkier than other lenses.

The broad perspective that telecentric lenses provide makes them helpful in the machine vision industry.

In short, you must talk about the requirements with a professional lens manufacturer. A reliable manufacturer can help you find the best lens type to customize.

How to Choose a Lens Material for Customization?

The quality and lifespan of an industrial lens are both affected by the material from which it is made. Common materials used by different manufacturers include glass, plastic, and quartz, each with advantages and disadvantages. At VicoImaging, we only use optical glass to produce industrial lenses.

Let’s look at each lens material in the below section.

-

- Optical glass

Optical glass consists of various elements, such as boron, aluminum, silicon, sodium, calcium, magrhesium, etc. It is a common material used in making optical instruments and devices.Besides high transparency, optical glass also have different optical properties, such as dispersion.Industrial lenses made of optical glass typically have a higher refractive index, giving them a slimmer, smooth, and attractive appearance. - Quartz glass

Quartz glass is composed of silica. It has a high chemical corrosion resistant and temperture stability properties. Thus, it is used in chemical laboratories and applications with high temperature processing. - Soda glass

Soda glass, also known as ordinary glass or silicate glass, is mainly composed of three major elements – silicate, carbonate, and oxide. Although it is the most common glass type used in making various daily necessities and building materials, some manufacturers use it for making industrial lenses.

- Optical glass

We can differentiate these three glass types based on their properties and composition. Optical and quartz glass will be perfect choice if you want higher purity degrees and superior optical properties. Likewise, soda glass is quite ubiquitous and affordable.

Quartz lenses are more expensive among all these three types because of their superior heat resistance capability.

Even though some manufacturers prefer plastic material for making their lenses, VicoImaging prefers only optical glass material. Glass lenses are more durable and long-lasting than plastic ones. That’s why they are little bit pricey.

Plastic lenses can be lightweight and more cost-effective than glass. But, they may shatter under extreme heat and can exhibit scratches over time.

What Are the Necessary Performance Requirements of a Customized Industrial Lens?

The resolution, depth of field, and distortion are only a few specs that influence an industrial lens’s performance. Other critical factors include working distance, required magnification, and image sensor format.

These details help to select the lens type and material that will perform best for the given task.

The application and the expected results can determine the performance requirements of an industrial lens. When deciding on the necessary performance parameters for an industrial lens, the following aspects should be taken into account.

Magnification

The item’s size, the distance between the lens and the object, and the intended field of view can help determine the amount of magnification needed. A higher magnification lens is necessary when observing distant or tiny things, and vice versa.

Depth of Field

The distance range across which an object remains sharply in focus is known as the depth of field. Application and needed accuracy will determine the minimum depth of field that must be achieved.

When working with constantly moving things or if pinpoint accuracy is needed, a deeper depth of field is necessary.

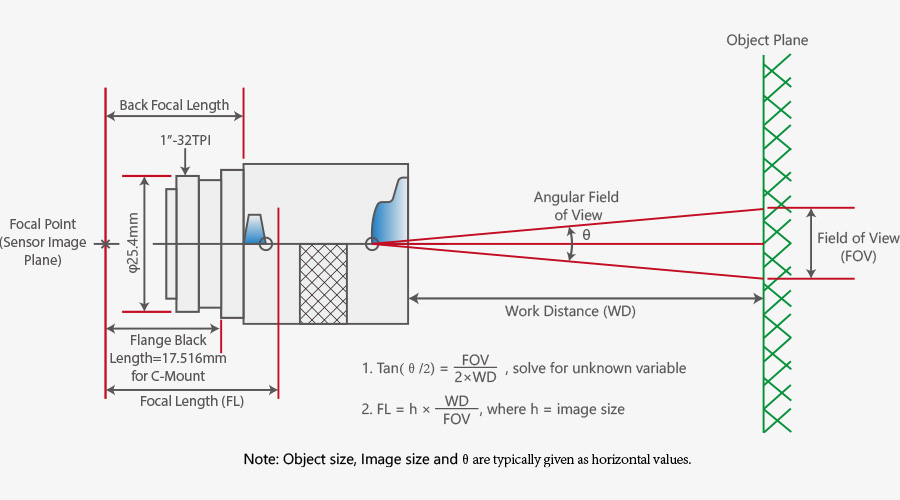

Focal Length

The lens’s focal length is crucial for precise imaging because it affects the distance between the industrial lens and the object.

The size and distance of the target, the intended magnification, and the desired field of view determine the focal length needed.

Aperture

The depth of field and a picture’s brightness are both affected by the lens’ aperture, which controls how much light enters the lens.

When determining the necessary aperture, consider both the application’s illumination and the quality of the final picture.

Resolution

The detail in the picture dictates the minimum acceptable resolution. Applications like microelectronics production and biological imaging need higher resolutions because of the necessity to capture small details.

Distortion

Lenses may cause distortion, which is when the picture is warped somehow.

Depending on the task at hand, a certain amount of distortion is tolerable, while less distortion is preferred in the case of precise jobs.

Coatings

Lenses may have coatings added to them to enhance their functionality in specific contexts, such as lowering reflections or increasing contrast. The necessary coatings depend on the lens’ application and required picture quality.

Working Closely with a Professional Industrial Lens Manufacturer: Creating Customized Solutions for Your Needs

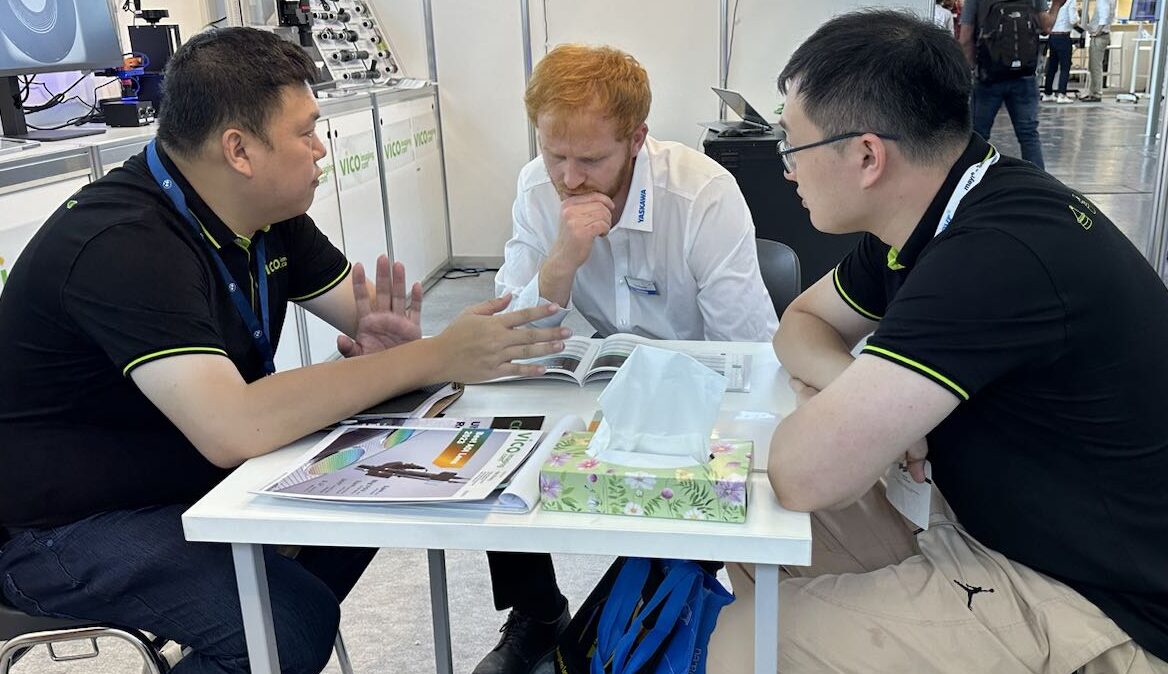

Industrial lenses may be customized with the help of a lens maker. A manufacturer can advise you on the best lens type, design, and materials. Besides, a manufacturer can also assist in testing the lens to guarantee it is up to par.

When discussing lens modifications with a lens maker, remember the following points:

Define the Requirements

Before contacting a lens maker, note your applications and needs by outlining your detailed specifications.

Considerations including camera sensor type, focal length, aperture, field of view, and picture quality are crucial points to discuss with the lens manufacturer.

Contact the Manufacturer

Contact a lens maker after you have a firm grasp of your specifications. Please be specific when describing your application and the image quality you need.

Collaborate on Design

The lens maker will collaborate with you to create a lens design that is tailored to your needs. There might be a lot of back-and-forth discussion and design tweaking involved in this process.

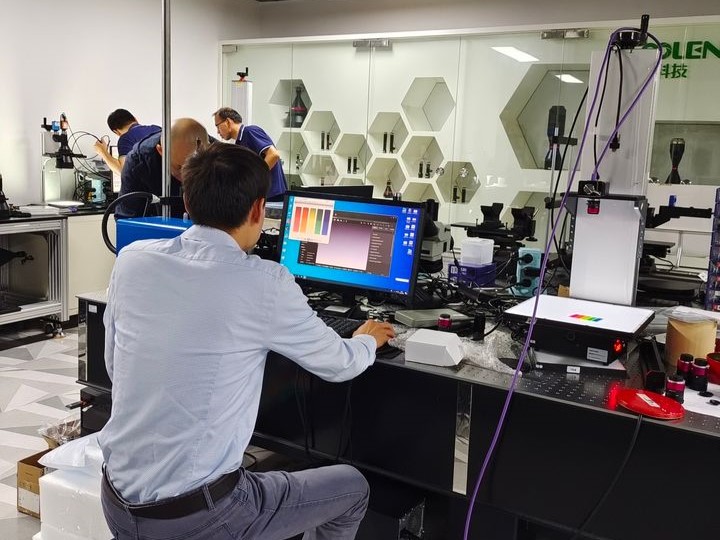

Prototype and Testing

After settling on a final design, the lens manufacturer will build a prototype of the lens and put it through a series of tests.

It will ensure that the customized lens measures up to your expectations. If the prototype lens fulfills your standards, the manufacturer will mass-produce it.

Production

Making a bigger batch of lenses that are identical to the prototype is what this entails.

Quality Control

The lenses will be tested at many manufacturing stages to guarantee they are up to par with the required quality standards.

Delivery

The lenses will be sent to you after they have been produced and have met all quality standards.

To create a lens tailored to your needs, you should work closely with the manufacturer and provide extensive information about your application and requirements.

How to Evaluate a Customized Lens for Industrial Use?

Testing and evaluation are essential if you want your custom-made industrial lens to operate as expected. The following are some particular methods for evaluating the quality of a tailor-made industrial lens:

Testing the Lens under Various Operating Conditions

It’s crucial to test the customized industrial lens in various settings to guarantee peak performance in any environment. The lens has to be examined in multiple conditions, from bright to dim, from close to far.

Likewise, testing the lens with different items and materials is essential to ensure it holds up under all conditions. It is also crucial to check the lens’s compatibility and performance with various imaging systems.

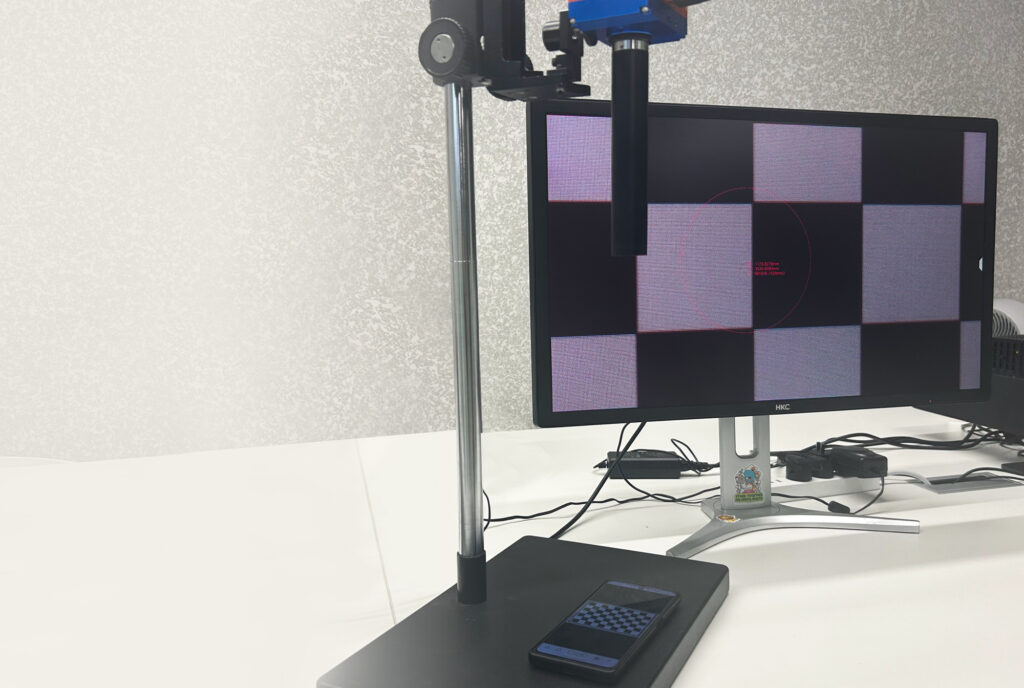

Customers must know the working environment where they want to use the lens. We will select the most suitable lens or customize a new one at our laboratory. We can also simulate a similar environment at our factory and set up a demo.

After that, we will capture an image under specified conditions to check the imaging results. It ensures that our lenses meet the customer’s requirements.

Customers can place their orders directly if the image quality and testing results are satisfactory. We will also provide the required data about lens specifications, including magnification, WD, FOV illumination, etc.

Comparing the Results to Expected Values

The second step of evaluating a custom-made lens is comparing the results to the predicted values established before the testing begins.

Huge differences between observed and predicted values suggest that the lens design may require tweaking.

Application-specific considerations include things like resolution, magnification, and depth of field. After putting the lens through its tests under different settings, it’s time to see how it performs against the norm.

Ensuring That the Lens Meets the Desired Performance Specifications

Third, the lens must be tested to ensure it delivers on the desired performance criteria established before testing ever begins on the customized industrial lens.

The lens must undergo extensive testing to guarantee it meets the performance claims. If the lens’s performance falls below expectations, it may be necessary to revise either its design or the testing procedures.

Environmental Testing

A lens might provide inaccurate detection results due to various operating environments. For example, vibrations caused by mechanical arms might affect the lens performance.

Thus, environmental testing of the lens may be required for evaluating it in a variety of operational circumstances. This testing confirms the lens provides accurate detection results under the required operating conditions. It also ensures the lens can resist extreme circumstances present in production lines.

Performance Repeatability Testing

When evaluating a lens for performance repeatability, many tests are conducted to confirm that the lens consistently delivers the same results.

It is helpful in situations when repeatable, precise measurements are essential. The lens must be tested repeatedly under the same circumstances to provide reliable readings.

Calibration Testing

Calibration testing is essential to guarantee the lens delivers precise readings and pictures.

To do this, we need to measure the lens’s output and then compare it to an established norm or reference. If you want your lens to work correctly, you must calibrate it often.

User Testing

User testing evaluates the lens’s usability, dependability, and general performance in the hands of actual clients.

The design of the lens may be improved with the help of user reviews collected via testing.

Durability Testing

The eighth step is durability testing, which entails testing the lens to see whether it can resist the stresses of industrial usage.

Lenses can be tested to see how well they hold up against things like harsh use, scratches, and general wear and tear.

The reliability of a lens’s performance depends on whether or not its design has been subjected to rigorous durability testing.

Field Testing

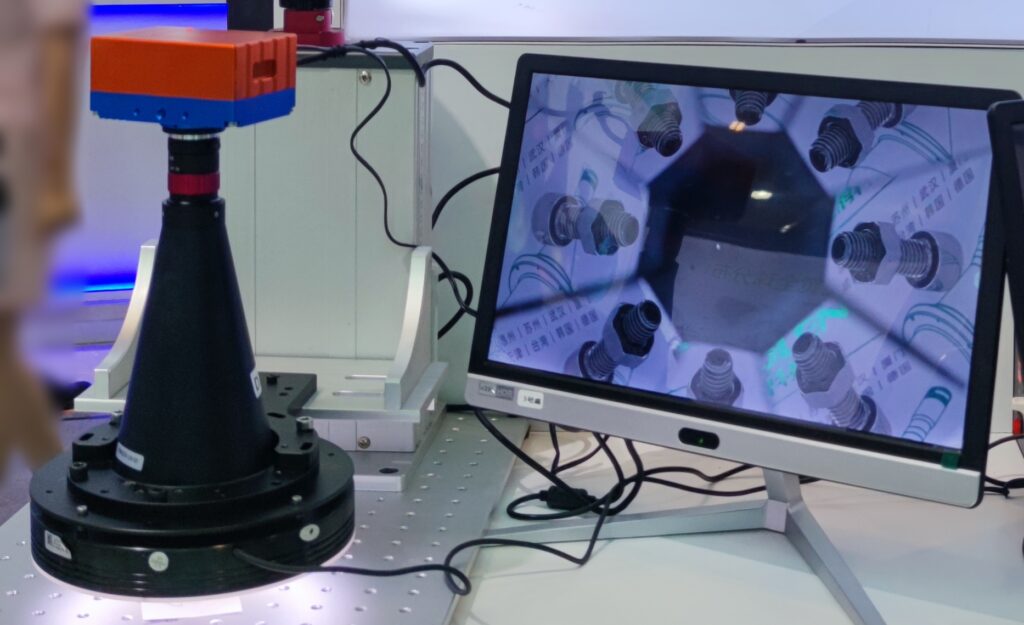

A custom-made lens must undergo field testing to assess its performance in the intended application. It entails putting the lens through tests in a real-world industrial setting.

The lens may need to be examined in several manufacturing settings and machinery configurations. The lens’s performance in real-world settings may be evaluated via field testing, which can reveal problems that weren’t noticeable in the lab.

Quality Control Testing

The tenth and last step is quality control testing, where the lens is tested to see whether it measures up to expectations set by authorities in the field.

ISO, industry standards, and any applicable governmental requirements may need to be tested. Quality control testing is necessary to guarantee the lens is suitable for industrial use.

A custom-made industrial lens is often created for its intended purpose. It satisfies all essential standards and regulations.

A professional lens manufacturer can help you achieve this by incorporating the testing and assessment processes mentioned above.

What Are the Common Applications of Customized Industrial Lenses?

Because of their adaptability and effectiveness, customized industrial lenses are integral parts of several machines and tools used in various fields.

More often than not, custom-made industrial lenses are used for the following:

Quality Assurance and Inspection

To better detect flaws, inconsistencies, and other quality concerns in Electronic goods, customized industrial lenses are often utilized in inspection and quality control applications. Uses in the automotive, electrical, and packaging sectors are only a few examples.

Machine Vision

Customized industrial lenses aid in the capturing of pictures and analysis of data for the purpose of controlling and monitoring production operations.

Robotics and Automation

Customized lenses also have applications in robotics, automation, and manufacturing lines.

When it comes to robotic arms and other equipment, custom industrial lenses are often employed in robotics and automation applications.

Medical Imaging

Industrial lenses may be modified for use in endoscopes and other medical equipment to aid in visualizing inside organs and tissues.

Scientific Research

To collect high-resolution pictures and data for analysis, scientists often employ customized industrial lenses in their work.

What Are the Best Practices for Maintaining Customized Industrial Lenses?

Customized industrial lenses may be maintained and used for a longer period, guaranteeing consistent and precise results in various settings.

So, some recommendations for servicing customized industrial lenses are as follows.

Correct Cleaning and Maintenance

Proper cleaning and maintenance practices are essential to preserving the effectiveness of custom-made industrial lenses.

To prevent scratching the lens, you must wipe it using a lint-free cloth or tissue paper and a lens cleaning solution, such as isopropyl alcohol.

The lens has to be handled with care to prevent scratches and dirt from getting on it.

Lens Protection

You must protect customized industrial lenses from environmental factors like dust, dirt, and moisture and physical damage like scratches. Correct handling is essential for extending their lifespan.

When the lens is not in use, it should be protected from dust and debris by placing a cap over it, and it should also be kept out of direct sunlight and high humidity.

Avoid damaging or contaminating the lens’s optical surfaces by contacting them with your naked fingers.

Regular Calibration and Testing

Calibration and testing should be performed often to guarantee that customized industrial lenses retain their accuracy and performance over time.

After examining its accuracy, resolution, and other performance indicators, recalibrating or changing the lens may be necessary.

By catching problems early, you may prevent them from becoming catastrophic, which can prolong your lens’s life.

What Problems Can Come Up When Making Custom Lenses for Industrial Use?

Some typical difficulties that may arise while producing customized lenses are as follows.

Incompatibility with the Chosen Imaging System

Incompatibility between the lens and the camera is a recurring problem that might develop throughout the customization process.

It may happen if the lens and camera (or other imaging components) are not well matched, leading to distortion or other picture quality issues.

Avoiding this problem requires a lens to be built in accordance with the imaging system.

Insufficient Optical Performance

Another potential problem during the lens-customization process is inadequate optical performance. It may happen if the lens has unacceptable levels of resolution, distortion, or any other optical property.

So to prevent this from happening, the lens should be meticulously designed and tailored to the application’s unique performance needs.

Price Overruns

Excessive spending might occur if the customization procedure for industrial lenses is not properly monitored.

You can avoid this issue by setting reasonable financial goals and maintaining constant communication with the lens manufacturer throughout the customizing process to keep prices in check.

Delivery Delays

Delivery delays may occur because of the intricacy and extra time required to make customized lenses. One way to stop this from happening is to work closely with the lens manufacturer to create firm deadlines for the customizing process.

Quality Issues

Lastly, poor production process management may lead to defective finished products when lenses are customized. It may lead to difficulties with performance, visual quality, or distortion.

If you want to prevent this problem, get your lenses from a reliable manufacturer with a history of producing high-quality custom lenses.

What Are the Methods of Diagnosing and Fixing These Problems?

Some methods for identifying and fixing typical problems with customized industrial lenses are outlined below.

Reviewing the Lens’s Performance

One helpful method for detecting and fixing problems with specialized industrial lenses is to examine them in different operational settings.

You can evaluate the lens’ performance by testing them at different distances from the object, vantage points, angles, and lighting conditions.

You can find issues like poor picture quality, distortion, and other performance faults by testing the lens in various settings.

Visual Inspection

Inspecting the lens visually is another helpful method for finding and fixing problems with specialized industrial lenses. One way to attain this goal is to examine the lens for any signs of wear or damage that could compromise its optical performance.

Alignment Testing

Alignment checks can be performed to ensure the lens fits in with the rest of the imaging components.

Through routine testing and calibration, lens problems may be detected and fixed before they worsen.

Seek Advice from the Lens Manufacturer

Finally, contacting the lens maker for assistance may be an efficient method of detecting and fixing problems with specialized industrial lenses.

The manufacturer can advise on testing and calibration techniques and how to resolve particular problems.

Remember, collaboration with the maker lets you catch problems early and fix them before they ruin your lens or camera’s image system. So, contact VicoImaging today!

Why Is It Important to Address Issues with the Customized Industrial Lens Early?

Resolving problems as soon as possible is crucial for maintaining the customized industrial lens’s performance and longevity.

It Helps Avoid Production Downtime

Downtime in manufacturing and production may be avoided if industrial lenses are maintained regularly. In the event of a lens failure, manufacturing would have to stop, which would reduce output and raise expenses.

Quick problem-solving reduces disruptions and keeps factories operating at peak efficiency.

It Helps Maintain Accuracy

The precision of any measurements or inspections being conducted might be compromised if the specialized industrial lens isn’t functioning correctly.

Inaccurate findings might result from waiting too long to fix the problem, leading to higher expenses and legal liabilities.

Accuracy can be maintained, and future expenses and complications can be avoided if problems are addressed immediately. Besides, it can also increase the lifespan of the specialized industrial lens.

Ignoring a problem that involves physical damage to the lens, for instance, might lead to the damage spreading and eventually making the lens useless. The lens may be saved or at least minimized in damage by taking the necessary steps.

Decreases Overall Maintenance Costs

Maintenance expenses for the specialized industrial lens may be lowered by quickly fixing any problems. The lens or other parts of the imaging system might become irreparably damaged if the problem is not fixed quickly.

Costs associated with fixing or replacing anything may be kept to a minimum if action is taken quickly.

FAQs:

Do I Really Need Customized Lenses?

It depends on your applications, needs, and overall results you want to achieve. If you work in a specific industry, you might need lens customization.

However, if you are working in a standard industry, let’s say, semiconductor making, then you can go for stock lenses that are already well-designed to suit your application needs. Check out our premium lens collections now!

Why Should I Go For Customized Lenses?

In recent years, the need for custom lenses has skyrocketed. Some lens buyers prefer to invest in a product that seems custom-made for their needs.

Customers who choose personalized or customized lenses get unique specifications in the product. It helps add or remove specific features from the lenses.

How Much Do Customized Lenses Cost?

The cost of making customized lenses depend heavily on your specifications. You can inform us about them, and you will get the best quote from a customer executive at VicoImaging.

What Time Will It Take to Get Customized Lenses?

The making of customized lenses involves many processes. From design, and prototype making, to final production, lens production can take anywhere from 15 to 30 days.

Manufacturers can face many unforeseen challenges during the actual production of customized lenses that may delay the process.

Why Should You Consider VicoImaging for Customizing Your Next Industrial Lens?

Our scope of knowledge and depth of services are here to help you customize a better industrial lens.

VicoImaging offers everything under one roof, from research and development to design, manufacturing, and system integration. Our engineers have designed and produced various customized industrial lenses by adopting this strategy.

The best part is that we look at the specifics of your application’s demands and then collaborate with you to design an optical solution that’s perfect for it.

Creating unique lenses is where our specialists and engineers shine. They’ve been doing it for years, making us a go-to lens supplier company.

Here is why you should consider VicoImaging for your next industrial lens customization project.

– Customization Facility: VicoImaging has both stock options and customized solutions readily available.

– Complete Setup: We’ll help you out all the way from conceptualization to prototype and mass manufacturing of industrial lenses.

– High Precision: We optimize our industrial lenses to provide the highest accuracy.

– Vigorous Testing: Our industrial lenses are examined under mutually approved test conditions.

– Quick Turnaround: Tell us when you need the industrial lenses! Our team will inform you about the required timeframe to produce a batch of high-quality industrial lenses.

Final Thoughts!

Industrial lens customization is an essential step in achieving optimal image quality for a given application. Quality control, machine vision, medical imaging, and scientific research are just some industrial applications that benefit from customization.

Understanding the application and factors like lighting, temperature, and humidity is essential for successfully customizing an industrial lens. If you want your custom-made lens to meet your expectations, you must put it through rigorous testing and review.

Finally, we advise consulting with a reliable industrial lens manufacturer to ensure the major component of an imaging system is tailored to your needs. If configured and maintained correctly, industrial lenses can provide high-quality image data for years to come.

If you require a customized industrial lens, you can contact VicoImaging to get the best solution on any lens-related needs. Our industry experts can help you customize a suitable lens for your applications.