Introduction

Define machine vision

Machine vision is a technology that enables machines to visually perceive and interpret the world around them using imaging, sensors, and artificial intelligence algorithms. It allows automated systems to capture, process, and analyze images or video to make decisions or perform actions based on visual input.

Machine vision systems provide precise, consistent, and reliable inspection capabilities, detecting even minor defects that may be missed by human inspection. Besides, it can easily adapt to different products, configurations, and production requirements, offering flexibility in manufacturing environments where frequent changeovers are necessary.

In modern manufacturing in 2024, it plays a crucial role in ensuring product quality, optimizing production efficiency, and enhancing overall processes.

Read related post> A Beginner’s Guide to Machine Vision System

The role of industrial lenses in machine vision system

The role of the industrial lens in a machine vision system is critical, as it is the core component that captures and focuses light onto the image sensor. The lens quality directly impacts the clarity, accuracy, and reliability of the image. These aspects further affect the system’s performance in various tasks, such as measurement.

Choosing a proper lens ensures that every necessary detail can be captured by imaging systems. High precision is required in tiny defects inspection, code reading, or recognizing patterns. Even the smallest error may cause increased costs and reduced quality in some cases.

Define industrial lens and its purpose

Optical lenses are known simply as lenses, and their function is optical imaging. In a machine vision system, the main role of the lens is to focus the imaging target on the photosensitive surface of the image sensor.

Key components of industrial lenses

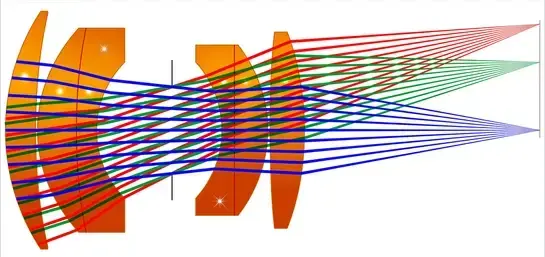

A lens generally consists of two primary components: the optical system and the mechanical assembly. The optical system comprises multiple lenses (or mirrors) that establish the correct object-image relationship, ensuring the generation of precise and clear images. It is the core of the lens.

The mechanical assembly includes parts that secure the optical elements, such as the lens barrel, lens mounts, retaining rings, and coupling rings. It also comprises adjustment mechanisms, such as aperture and focus rings, and connection interfaces like the commonly used C or CS mounts. Additionally, some lenses are equipped with electronic features like autofocus.

Types of industrial lenses

Fixed focal length lenses

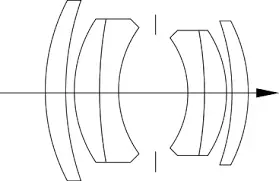

These are the most common types of lenses in machine vision. If a lens has a single focal length (such as a 30mm lens), it is usually a fixed focal length lens. This lens is typically a fixed focal length lens. It can still focus on different WDs, usually achieved by moving all of the individual lens elements together such that the corresponding spacing between them does not change.

Note that true fixed focal length lenses will always behave as in the pictures below. However, some lenses have a “floating element focus”, where the relative element spacing changes through focus. This change in spacing results in a shift in the system’s focal length, although typically not significant enough to differentiate them.

Fixed focal length lenses are ideal for the majority of machine vision applications due to their flexibility and high performance.

Fixed focal length lenses can be used in most cases:

-> general parts inspection,

-> barcode reading,

-> biometric and document scanning,

-> license plate reading,

-> other types of optical character recognition (OCR) or optical character verification (OCV).

The AFOV of a fixed focal length lens is determined by its focal length and sensor size. I am the target text.As the focal length decreases, the AFOV increases. Their relationship is linear; therefore, a 50mm focal length lens will have an AFOV that is twice as large as a 100mm lens.

These lenses are considered variable magnification lenses for this blog because they can be focused at different distances and have different magnifications.

Read related post> The Integral Role of FA Lenses in Machine Vision for Automation Manufacturing

Zoom lenses

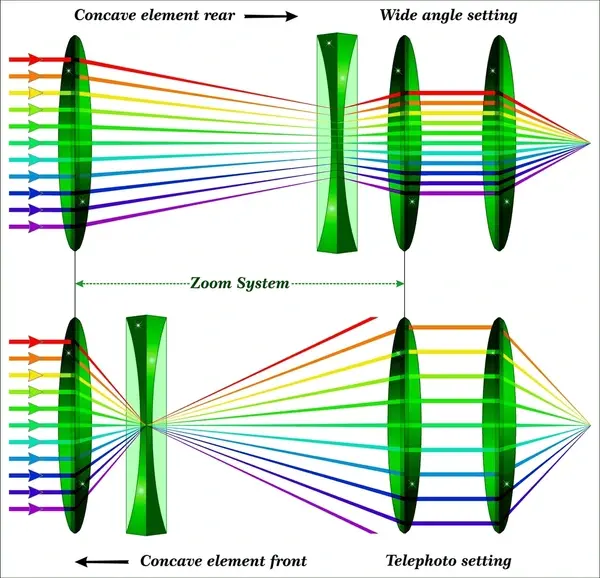

Under the common premise of a fixed WD, the AFOV of a fixed focal length lens remains constant while in contrast, the AFOV changes accordingly with the change of the focal length of a zoom lens. Zoom lenses are, therefore, ideal for applications requiring flexibility without high resolution during use. Unless a FOV actively needs to change while imaging, it is usually not the best choice. In addition, when using a zoom lens to change the FOV, a stepper motor is required to quickly and accurately adjust the focal length.

Zoom lenses are specified with particular zoom ratios, which can be calculated by dividing the longest focal length by the shortest for any given lens. For example, if the focal length of a zoom lens varies from 6mm to 36mm, it is considered a 6X zoom lens (36mm/6mm = 6X). This can also be expressed as a 6:1 zoom ratio for the lens.

The picture above shows the same zoom lens set to two different focal lengths. Note that both relative element spacing and distance to the image surface change, although the WD has not changed. These complex mechanics increase the lens system’s cost, as they require precise movements to adjust the focal length and maintain focus simultaneously.

Zoom lenses cannot achieve as high resolution as a comparably priced fixed focal length lens due to the complex mechanics and multitasking of optical elements. They are designed to perform well over a range of focal lengths, but this broad functionality can impact their overall performance.

Other interesting optical properties may arise due to the complex movements in a zoom lens. The f/# can change as the focal length changes, depending on the lens design. This type of design is typically avoided for photography or videography lenses.

But for machine vision lenses, this is often not the case. As the magnification changes, the effective f/# will still vary, resulting in different exposures.

As mentioned in the previous section ‘Fixed focal length lenses‘, when zoom lenses change their FOV, they remain in focus. When a lens is defocused while its focal length is adjusted, it should be more accurately termed a varifocal lens, not a zoom lens. Choosing a zoom lens is similar to choosing a fixed focal length lens.

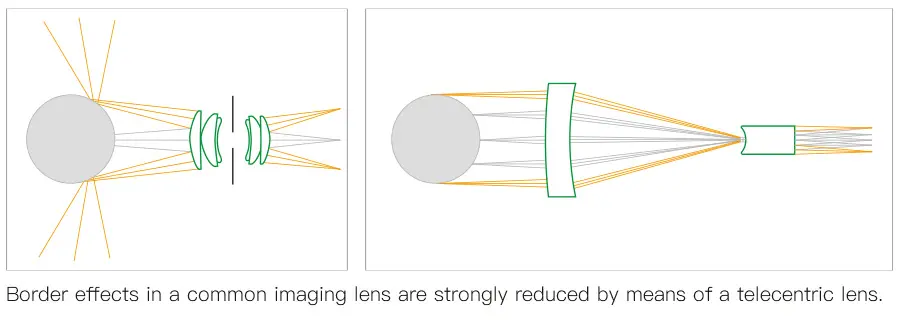

Telecentric lenses

Telecentric lenses are mainly designed for correcting the parallax of conventional lenses. They can be used within a certain object distance so that the magnification of the image produced does not change with the object distance. This is very important for the case where the measured object is not on the same object surface.

Compared to fixed-focus or zoom lenses, telecentric lenses are more complex to design and they usually require more optical elements to achieve telecentricity. The precise arrangement and high-quality manufacturing of these optical elements result in higher manufacturing costs for telecentric lenses. At the same time, telecentric lenses are typically larger and heavier due to their complicated design.

There are three advantages of telecentric lenses:

Constant magnification: The foremost feature of a telecentric lens is its ability to maintain uniform magnification, which is crucial for applications where precision is paramount.

Constant magnification: The foremost feature of a telecentric lens is its ability to maintain uniform magnification, which is crucial for applications where precision is paramount.

Reduced perspective error: These lenses significantly minimize perspective distortion, a common issue with FA lenses, especially when inspecting objects of varying sizes or at different distances.

Depth of field: Telecentric lenses offer an extended depth of field compared to FA lenses, allowing for clearer imaging over a range of distances.

Read related post> Understanding Telecentric Lenses: Revolutionizing Precision in Imaging

Microscope objectives

Microscope objectives are typically used to inspect extremely tiny objects. This requires an imaging system with magnification much greater than 1x. They are lenses with fixed magnification that only function properly at a single WD, which is generally quite small compared to other imaging lenses. Microscope objectives should be used when a high-magnification image is required and there are no strict constraints of minimum WD.

Factors to consider when choosing the right lens

As a complex and delicate component, imaging lenses play a crucial role in an imaging system. Making decisions when selecting lenses and weighing the trade-offs in the immediate results is not always easy. Lens specification sheets vary from one manufacturer to another, making it difficult to compare them. Even when determining the required type of lens for a particular use, the subsequent selection can still be challenging. Is a fixed focus lens the best choice? What about a zoom lens or a telecentric lens?

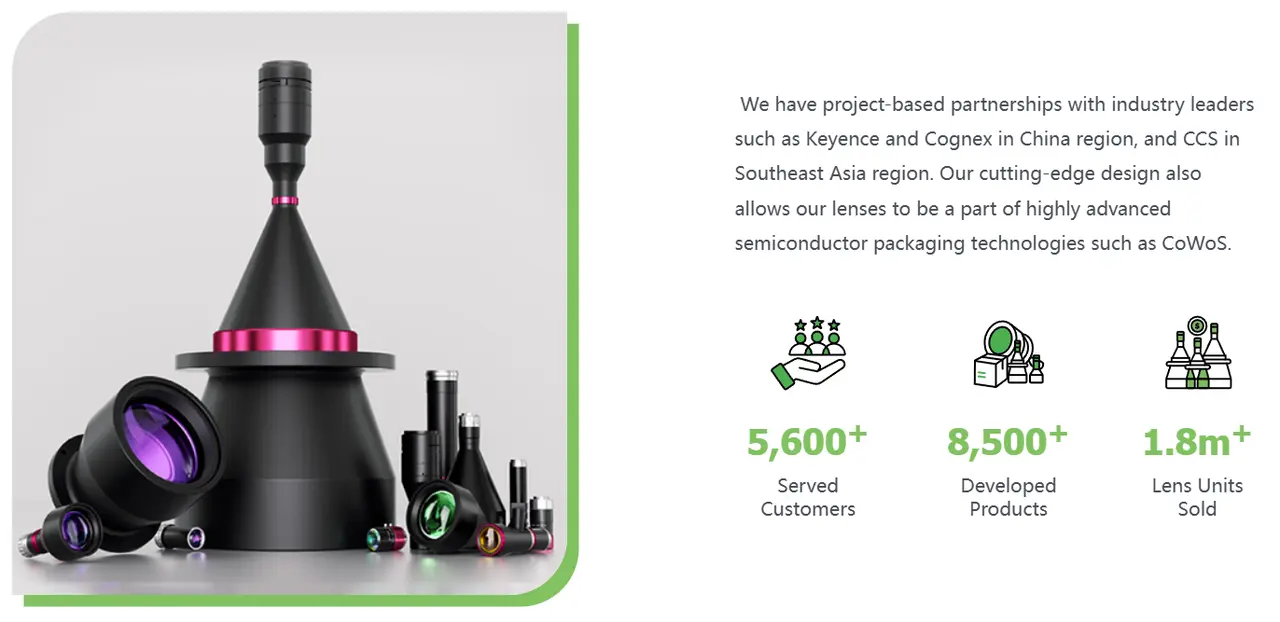

VICO Imaging® is one of the world’s leading providers of industrial machine vision solutions. Buying optics can be simple and easy. It doesn’t matter what kind of optics you need, whether it is industrial lenses, illuminations, calibration targets, or other optical accessories. With our extensive experience, we can provide a customized solution tailored to your needs on a one-to-one basis.

Read related post> Tips for Choosing Industrial Lenses

Conclusion

Imaging lenses are essential in imaging systems. Choosing the right lens affects the image quality and the overall performance of the system. However, due to the differences in various specification standards, the process of comparing and selecting lenses can be very complicated. Therefore, we need to deeply appreciate the features of multiple lenses, such as fixed focal length lenses and telecentric lenses.

Besides, many key factors should be considered when choosing an industrial lens: WD, distortion, and DoF, to name a few. All these factors impact the lens quality and the overall performance of the imaging system. So we need to strike a balance between performance and costs to find the most ideal lens for efficient operation and reliability of the machine vision system.