Introduction

With the automobile industry’s rapid development, wheel hubs’ output is growing continuously. As the supporting component of the automobile, the wheel hub carries the weight and all loads of the vehicle and therefore is an important guarantee for vehicle safety. Its quality is closely related to driving safety. The valve port can prevent air pressure accumulation, help release excess air, and prevent excessive pressure from affecting stability or causing deformation. In addition, the main function of the valve port is to secure the wheel hub to the axle. The valve port fastens the wheel hub to the wheel hub seat of the axle through bolts for safe and stable wheel installation on the vehicle. In summary, ensuring the quality control of the wheel hub, valve ports, and bolt holes is crucial to guarantee the safety and performance of the vehicle.

In the past, automobile wheels were mainly inspected manually, leading to low efficiency and the inability to guarantee accurate results. With the continuous development of AOI (Automated Optical Inspection), people have gradually realized the important role of machine vision in wheel inspection. AOI is crucial in the automotive industry, especially for quality control. Besides, the wheel hub is an important part of an automobile. Its accuracy directly impacts the vehicle’s safety and driving stability.

Read related post> A Definitive Guide to Automated Optical Inspection (AOI) in 2024

Factors to consider when choosing a lens

Aperture: A wide aperture allows for more light to enter the lens, useful in low-light conditions for creating a shallow depth of field to isolate interferences.

Image quality: The lens should produce sharp and clear images with minimal distortion.

Portability and flexibility: If carrying and moving the lens are necessary, a light and compact lens may be preferable. Besides, a lens with a long working distance allows more flexibility when operating tasks and designing the inspection system.

Compatibility: Whether the lens is compatible with your camera’s mount or sensor format should always be taken into account.

There are other considerations for choosing a lens, including focal lengths, lens construction, or special designs like built-in illumination. By carefully considering these factors, we can select a lens that is well-suited for our wheel hub inspection.

Lens types

Fixed focal length lenses

If a lens has a single focal length (such as a 30mm lens), it is usually a fixed focal length lens. This lens is typically a fixed focal length lens. It can still focus on different WDs, traditionally achieved by moving all of the individual lens elements together so that the corresponding spacing between them does not change.

Note that true fixed focal length lenses will always behave as in the pictures below. However, some lenses have a “floating element focus”, where the relative element spacing changes through focus. This change in spacing results in a shift in the system’s focal length, although typically not significant enough to differentiate them.

Fixed focal length lenses are ideal for the majority of machine vision applications due to their flexibility and high performance.

The AFOV of a fixed focal length lens is determined by its focal length and sensor size. As the focal length decreases, the AFOV increases. Their relationship is linear; therefore, a 50mm focal length lens will have an AFOV that is twice as large as a 100mm lens. These lenses are considered variable magnification lenses for this blog because they can be focused at different distances and have different magnifications.

Zoom lenses

Under the common premise of a fixed WD, the AFOV of a fixed focal length lens remains constant, while in contrast, the AFOV changes accordingly with the change of the focal length of a zoom lens. Zoom lenses are, therefore, ideal for applications requiring flexibility, but this comes at the cost of potentially lower resolution compared to fixed focal length lenses. Fixed focal length lenses provide higher image quality and are generally more stable in terms of focus, making them ideal for applications where precision is paramount. When choosing between the two, consider the specific needs for FOV flexibility, resolution, and cost. If high resolution and consistent focus are essential, a fixed focal length lens might be the better choice. However, if the ability to change the field of view is crucial, a zoom lens is a viable option.

Read related post> A Closer Look at the Types of Industrial Lenses for Machine Vision

Telecentric lenses

Telecentric lenses are mainly designed for correcting the parallax of conventional lenses. They can be used within a certain object distance so that the magnification of the image produced does not change with the object distance. This is very important for the case where the measured object is not on the same object surface.

Compared to fixed-focus or zoom lenses, telecentric lenses are more complex to design and they usually require more optical elements to achieve telecentricity. The precise arrangement and high-quality manufacturing of these optical elements result in higher manufacturing costs for telecentric lenses. At the same time, telecentric lenses are typically larger and heavier due to their complicated design.

There are three advantages of telecentric lenses:

- Constant magnification: The foremost feature of a telecentric lens is its ability to maintain uniform magnification, which is crucial for applications where precision is paramount.

- Reduced perspective error: These lenses significantly minimize perspective distortion, a common issue with FA lenses, especially when inspecting objects of varying sizes or at different distances.

- Depth of field: Telecentric lenses offer an extended depth of field compared to FA lenses, allowing for clearer imaging over a range of distances.

Read related post> The Advantages of Telecentric Lens

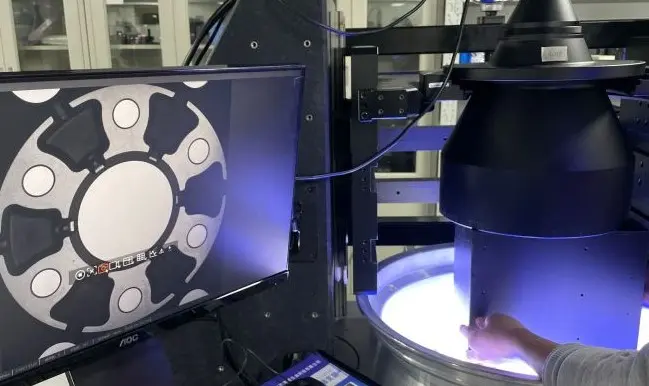

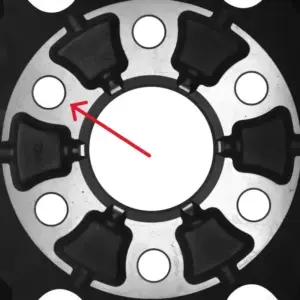

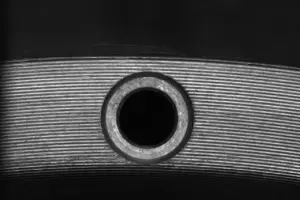

Case study: COOLENS®DTCM series for valve port and bolt hole inspection

The wheel hub, as a supporting part of the automobile, carries the weight and all loads of the vehicle and therefore impacts vehicle safety. The inspection of wheel hubs contains the defect inspection and size measurement of valve ports and bolt holes. Due to the metal surface, they reflect light, and bolt holes are widely distributed in a large area of the hub. Therefore, in this case, we chose the DTCM series for several reasons:

- High resolution: With resolution of up to 150MP and MTF30 (lp/mm) > 150, this series helps in capturing every detail. So precise images can be produced to measure dimension and position.

- Large FOV: Since the bolt holes are widely distributed in the large area of the hub, a large FOV of the lens is therefore required. With 26mm-300mm FOV, this series can easily cover all holes to make sure they are imaged once.

- Low distortion: This property ensures precise and accurate measurement of the position and dimension.

- Long WD: With quite a long WD, probing the lens into the object is avoided.

- Large image circle: With a large image circle, our lenses are compatible with sensors up to 67.6mm and cameras with 3.76μm pixel size.

Read related post> Ensuring Automotive Safety: DTCM Series for Valve Port and Bolt Hole Inspection

Conclusion

The rapid development of the automotive industry has led to an increase in demand for wheel hubs, which are crucial for vehicle safety. Wheel hubs support the weight and all loads of the car, so their quality is a key factor in ensuring driving safety. Accurate quality control of wheel hubs (including their valve ports and bolt holes) is crucial. Traditional manual inspection methods are inefficient and inaccurate in most cases. However, with the development of AOI, machine vision has become an important tool for wheel hub inspection, ensuring high precision and efficiency.

When choosing a proper lens for our inspection, imaging quality, image circle, compatibility, and design of long WD are considered due to the challenges in inspecting valve ports and bolt holes. Therefore, our DTCM series bi-telecentric lenses are the most ideal choice thanks to their benefits of high resolution, large FOV, low distortion, long WD, and large image circle. Overall, selecting the most tailored lens for a specific inspection contributes to enhanced quality control of products.