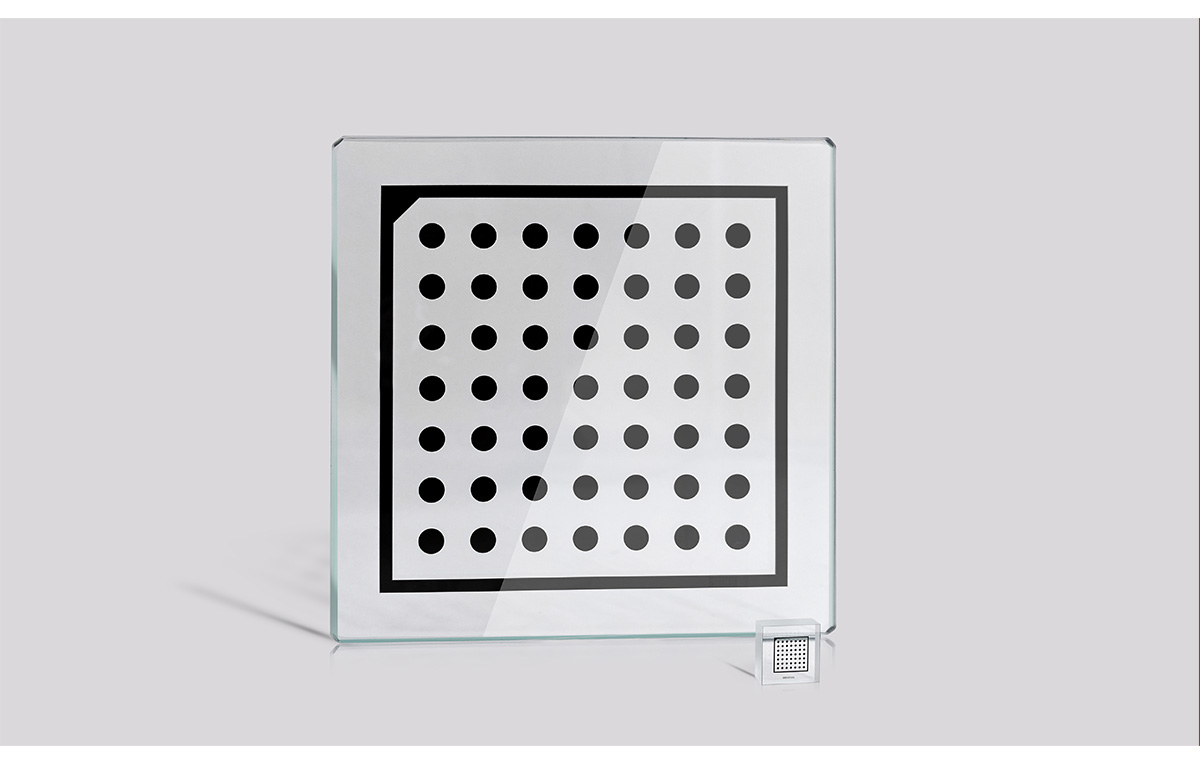

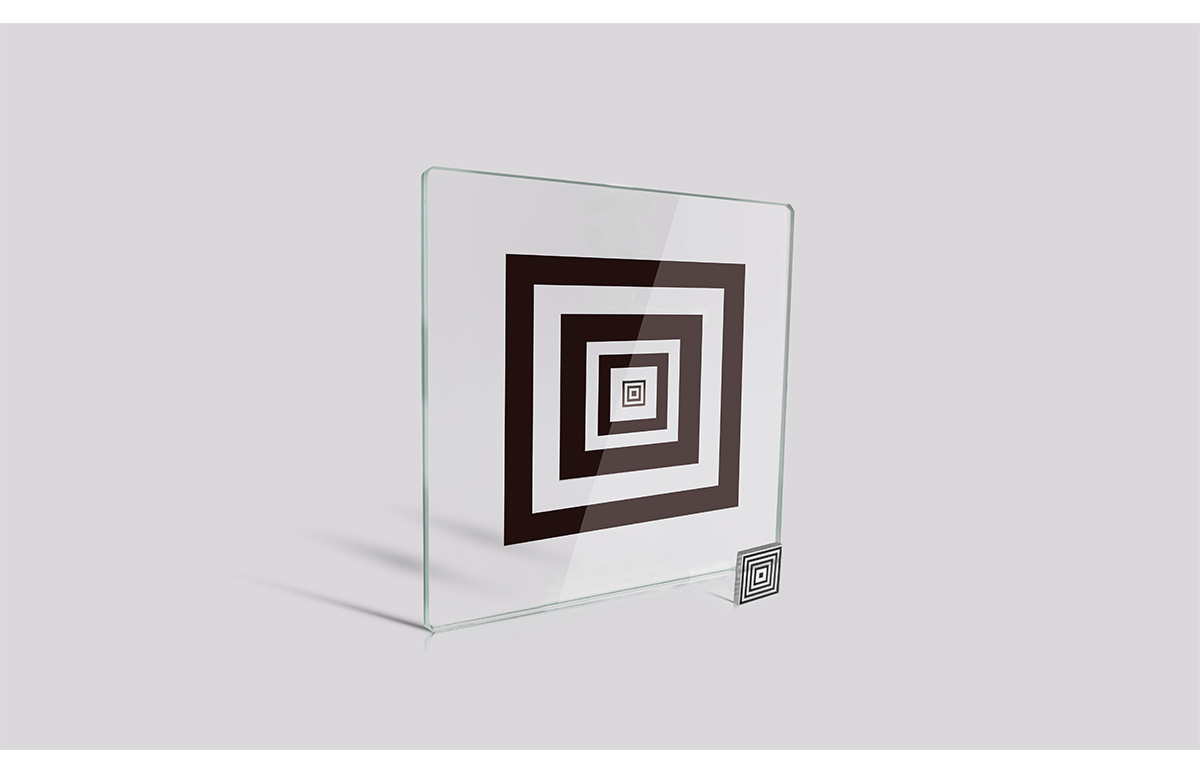

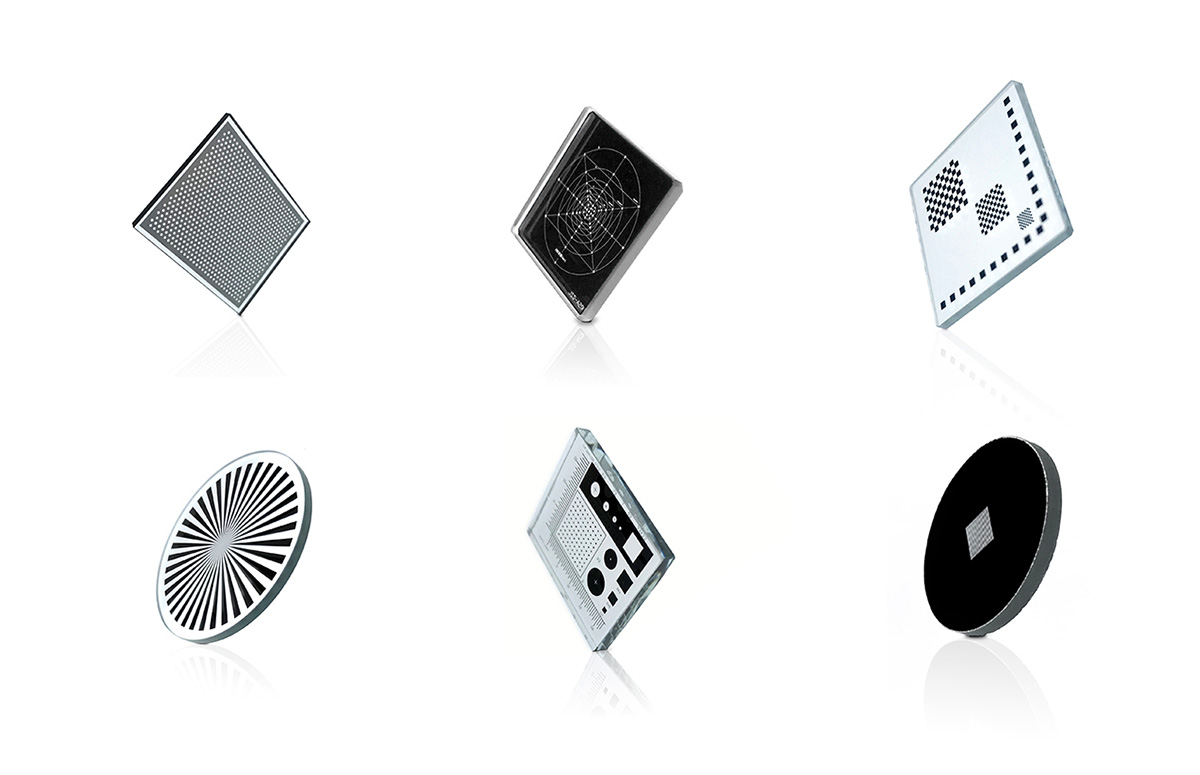

Custom Chrome on Glass Test Calibration Targets / Charts / Masks

Model NO. :

Glass Test Calibration Targets

| Product Specification | |||||||||||||||||

| Pattern | Substrate Material | ||||||||||||||||

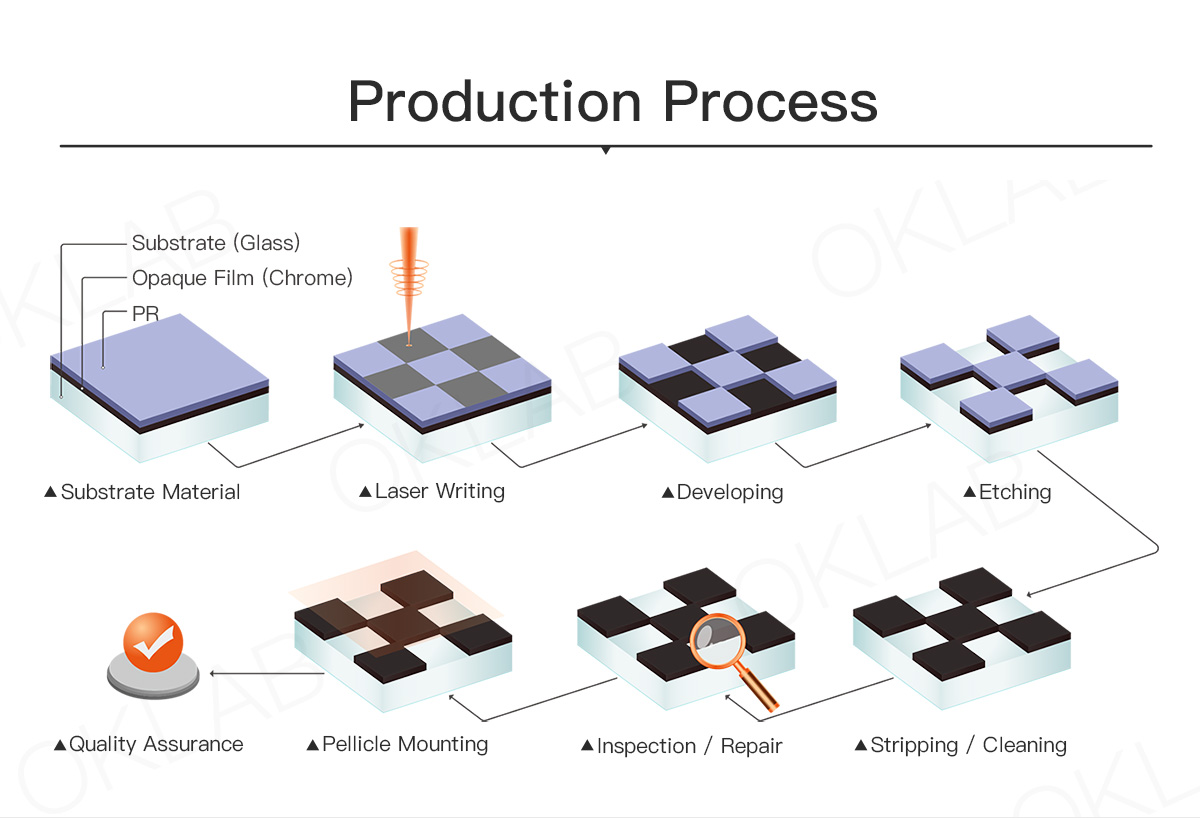

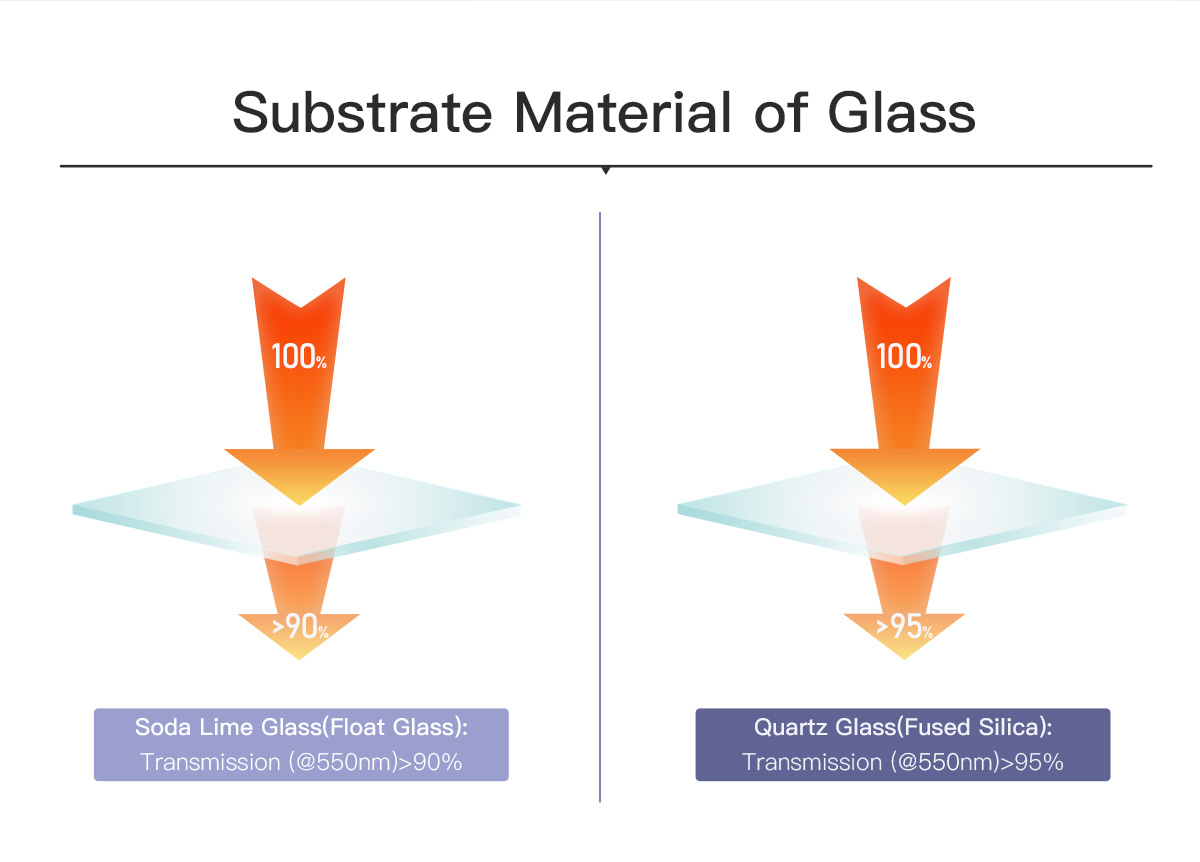

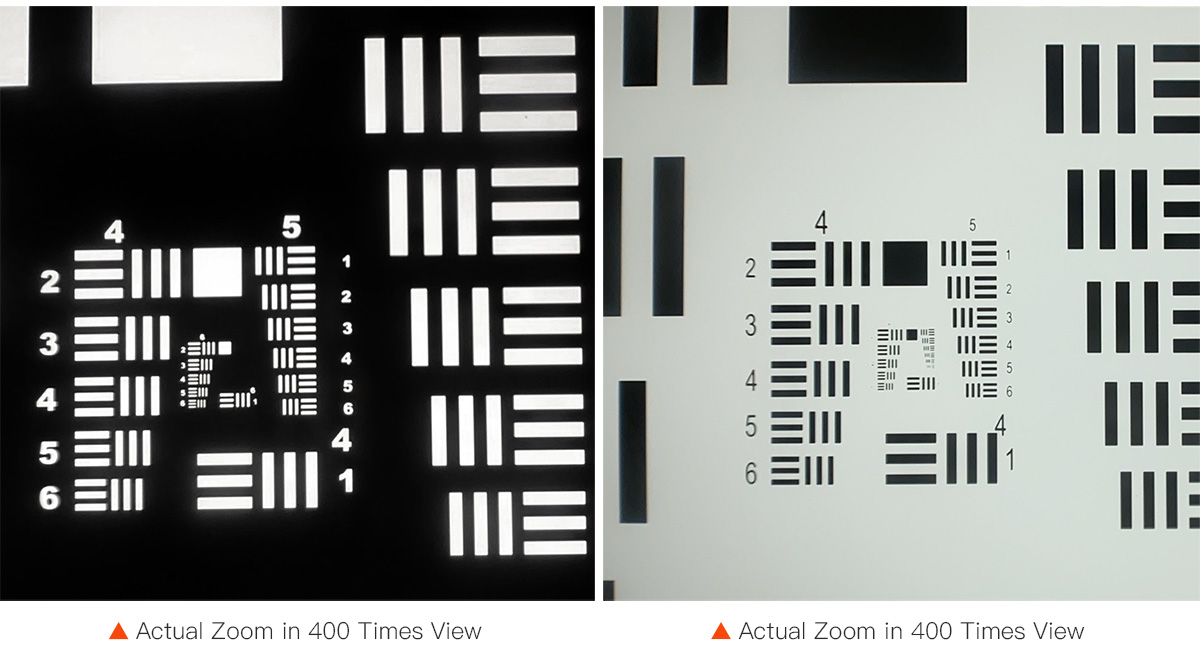

| Production Process | Laser Writing | Substrate Material of Glass | Soda Lime Glass (Float Glass) | Quartz Glass (Fused Silica) | |||||||||||||

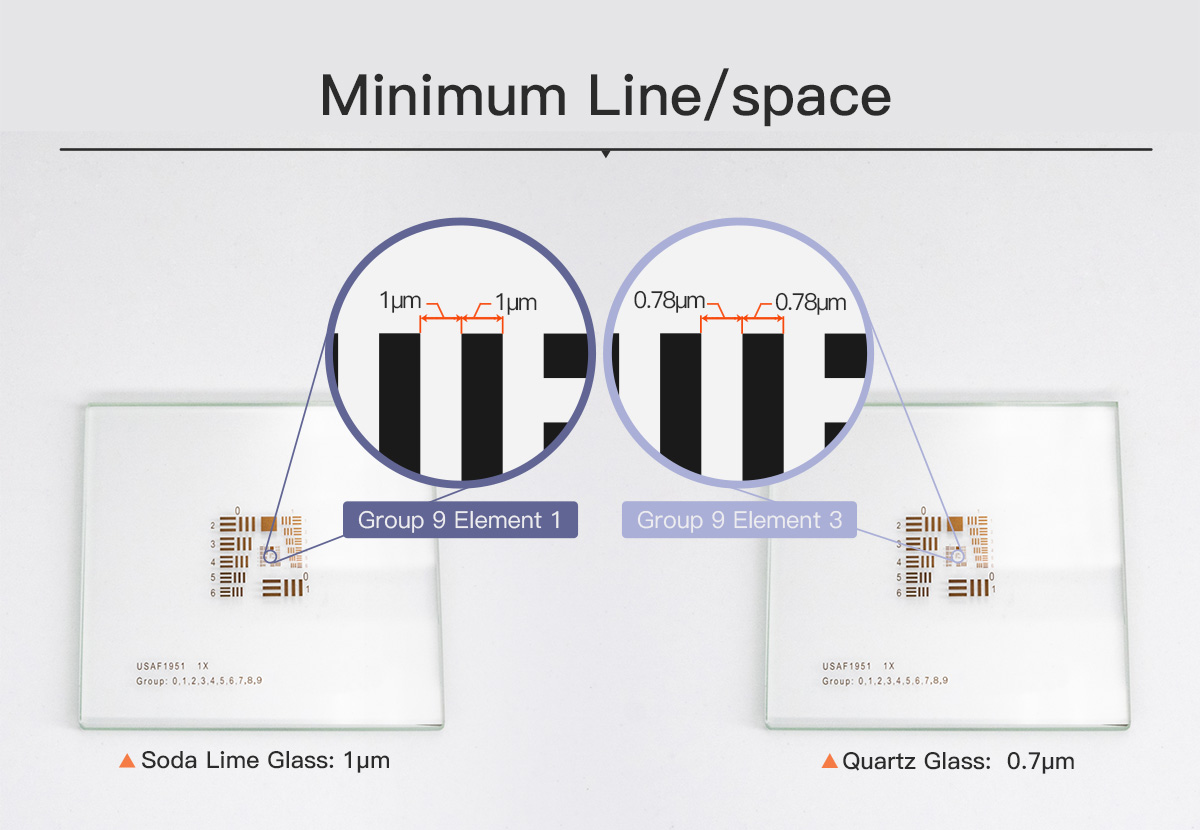

| Minimum Line/space | 1μm / 0.7μm | Transmission (@550nm) | >90% | >95% | |||||||||||||

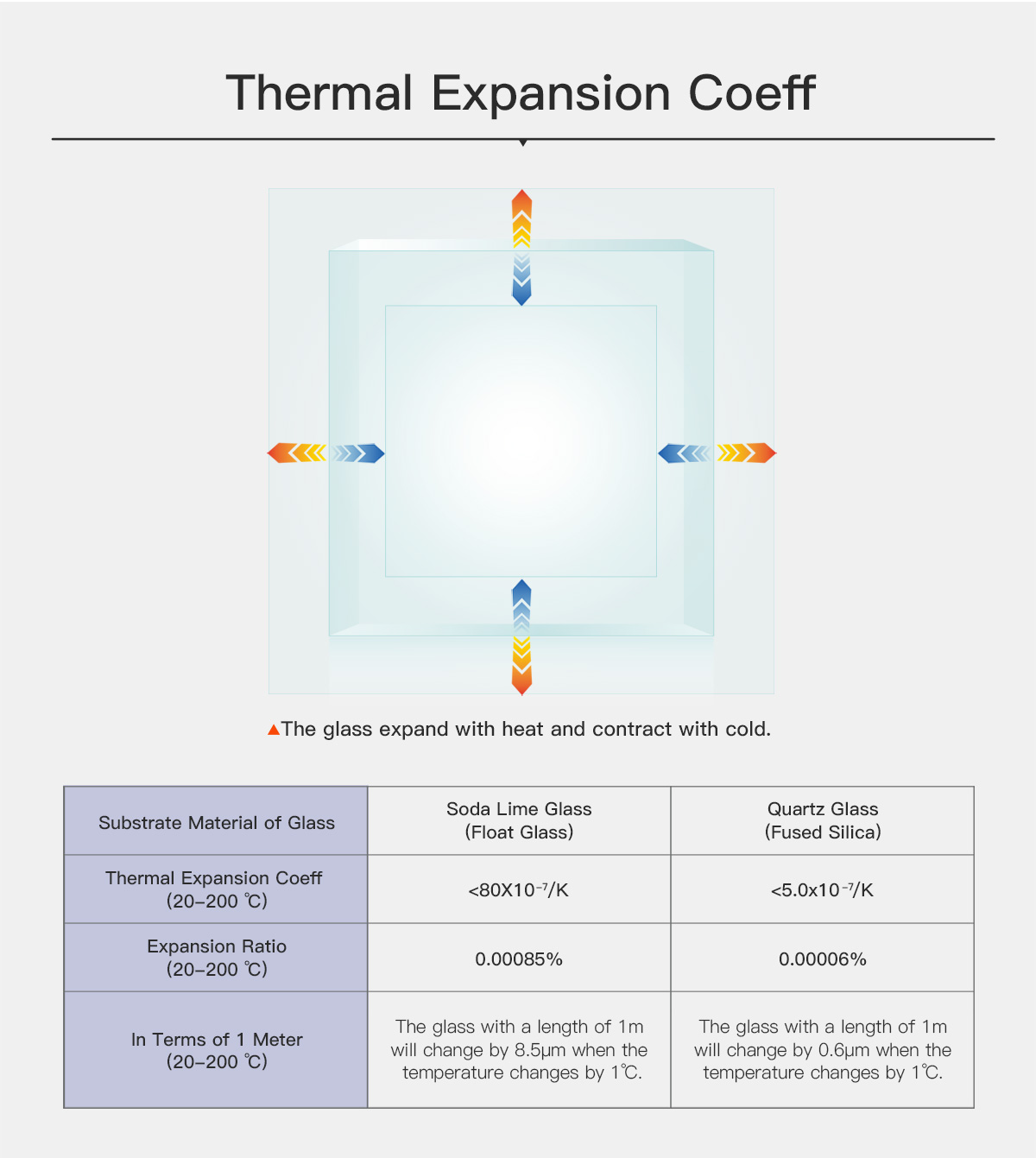

| Feature Accuracy Overall Accuracy | ±1μm | Thermal Expansion Coeff (20-200 ℃) | <80X10⁻⁷/K | <5.0x10⁻⁷/K | |||||||||||||

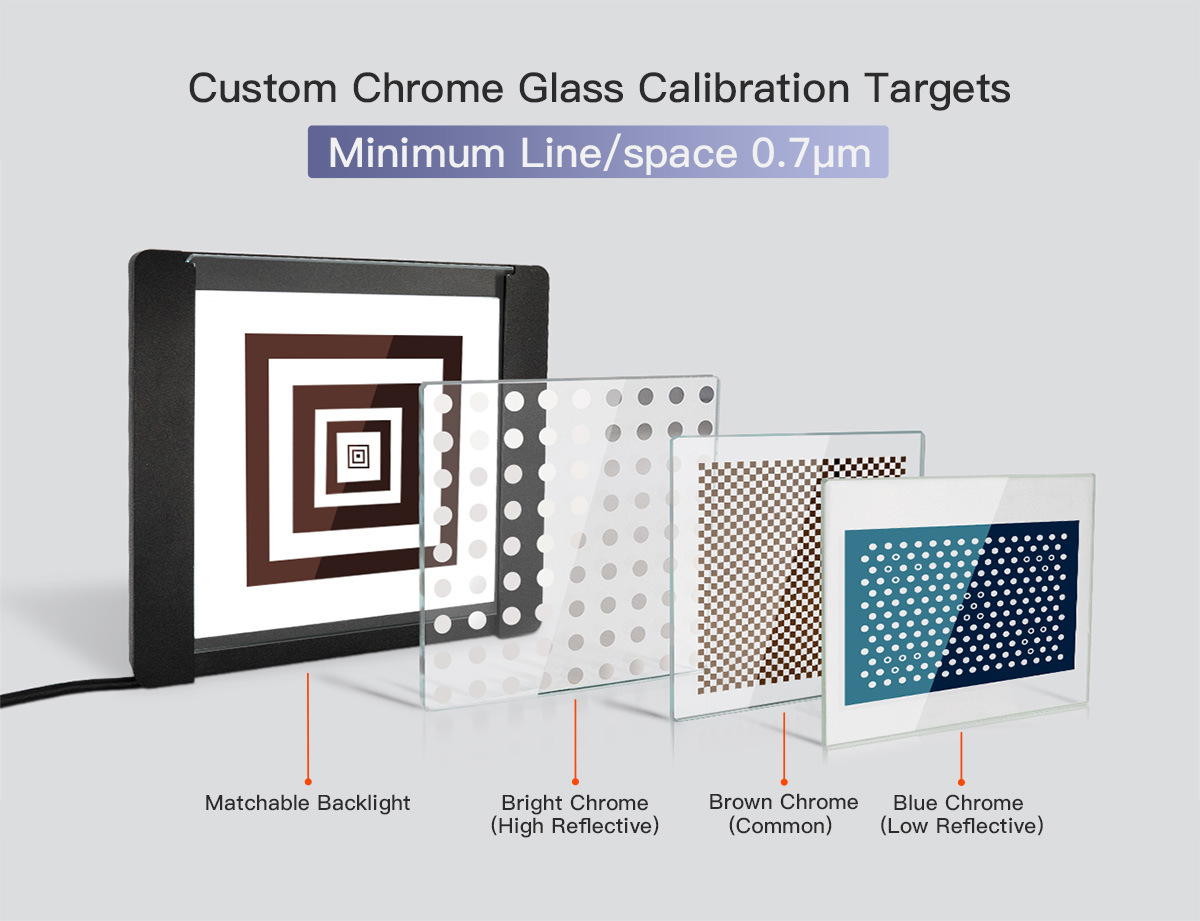

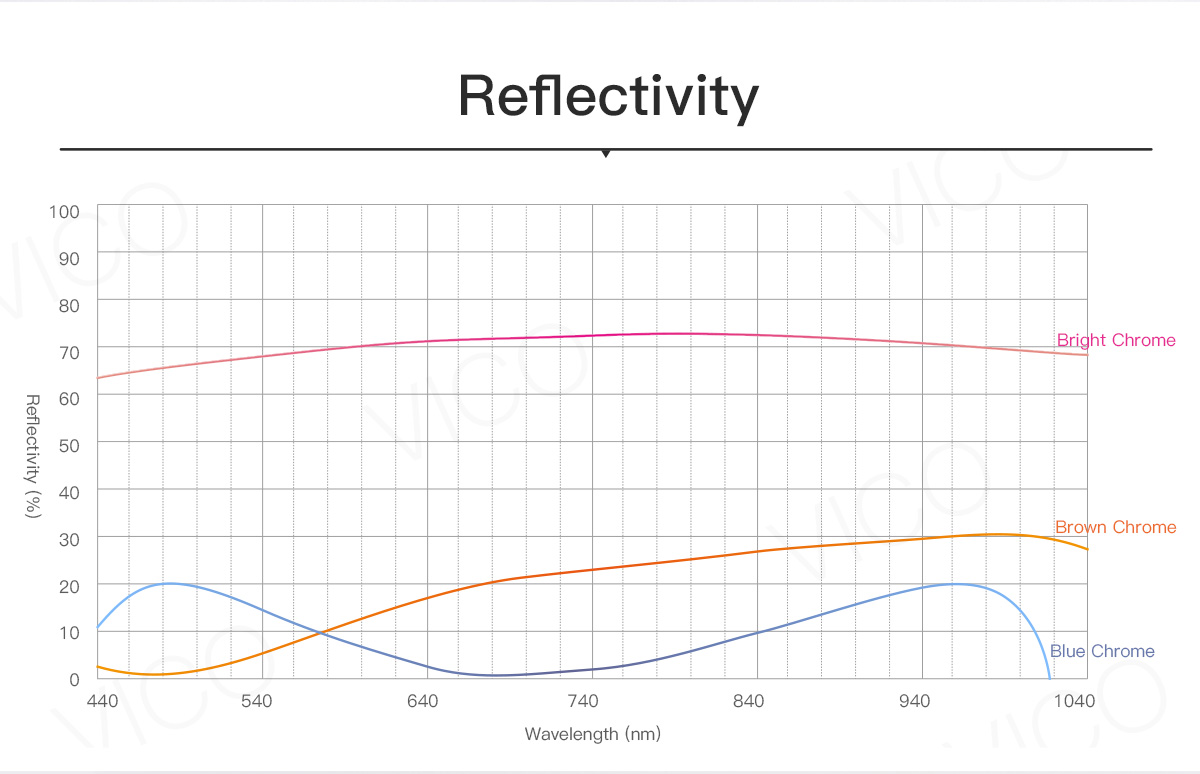

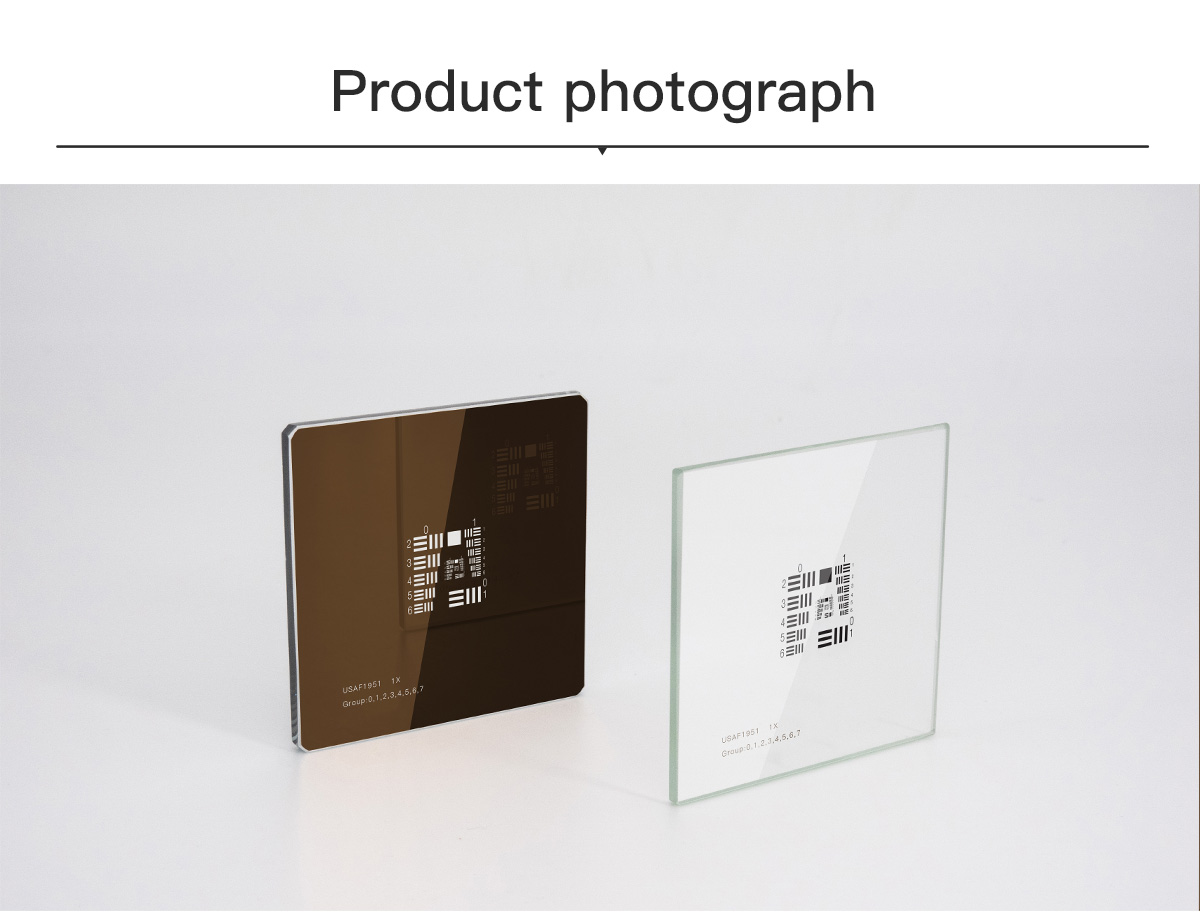

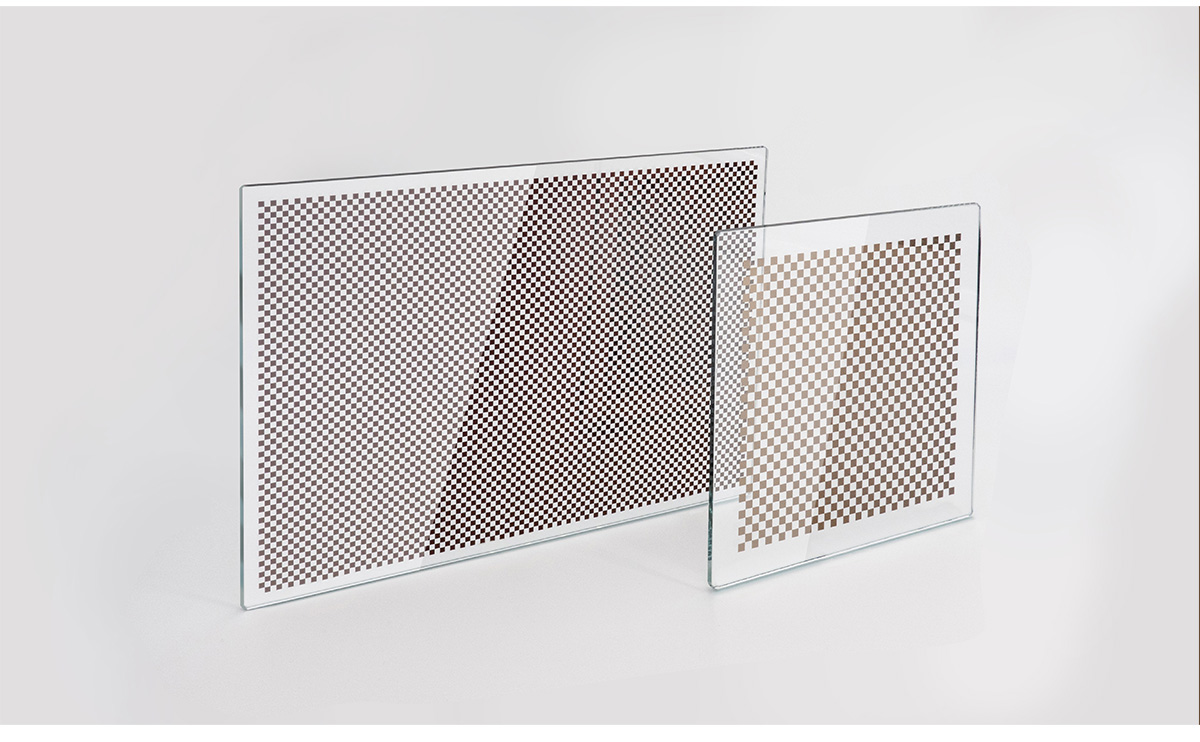

| Coating Type | Bright Chrome (High Reflective) | Brown Chrome (Usual) | Blue Chrome (Low Reflective) | Expansion Ratio (20-200 ℃) | 0.00085% (8.5μm/℃ of 1m) | 0.00006% (0.6μm/℃ of 1m) | |||||||||||

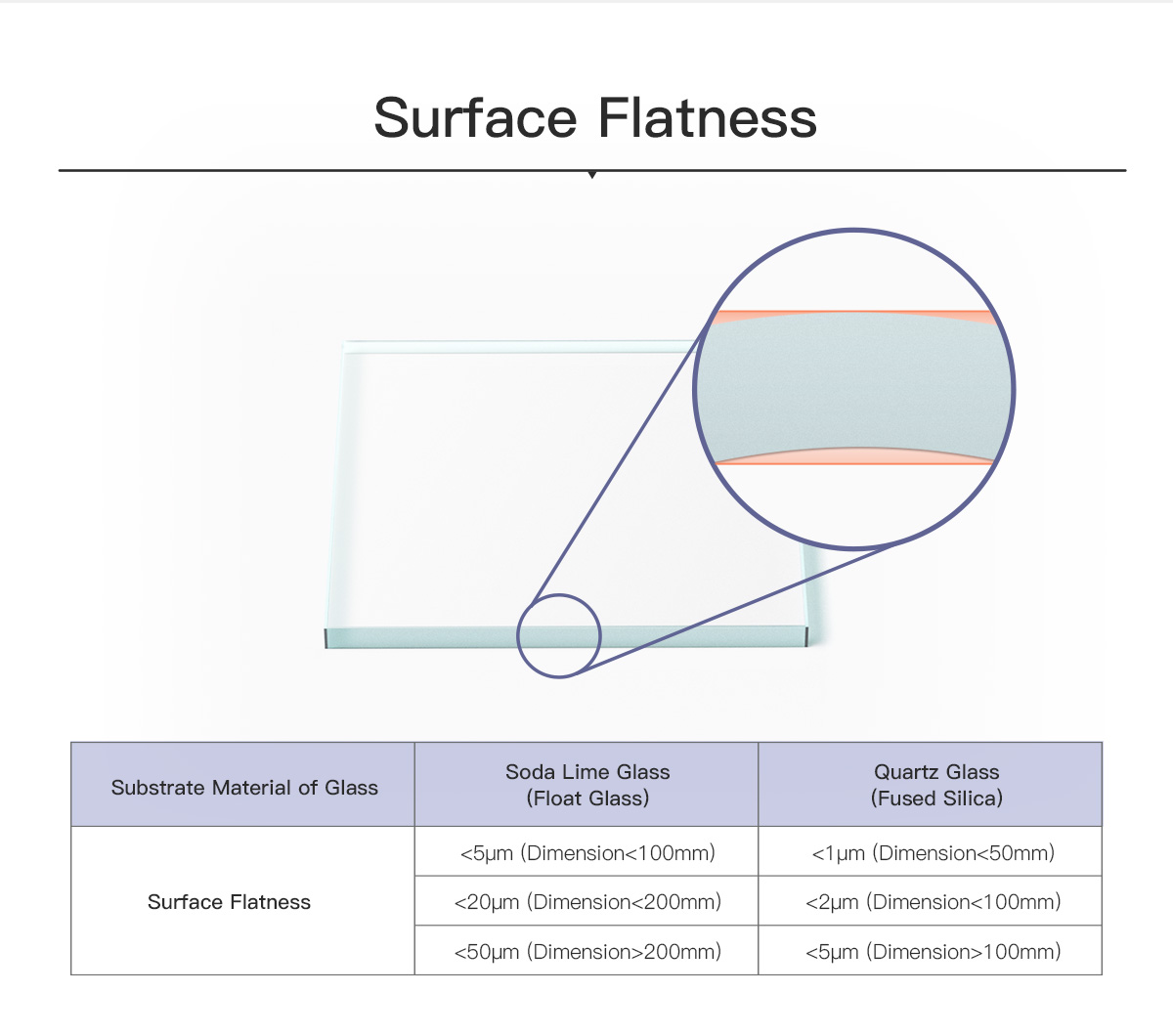

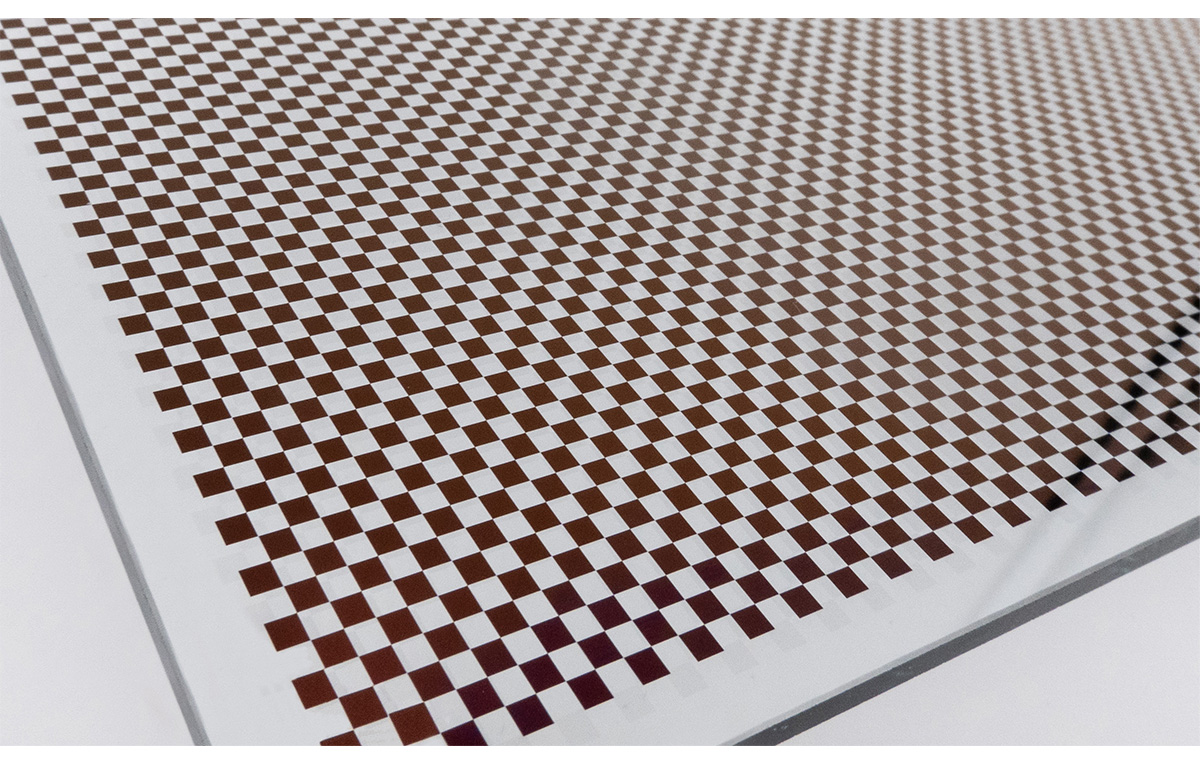

| Reflectivity | < 66% @550nm | <6% @550nm | < 13.4% @550nm | Surface Flatness | <5μm (Dimension<100mm) | <1μm (Dimension<50mm) | |||||||||||

| < 73% @650nm | < 17% @650nm | < 1.8% @650nm | <20μm (Dimension<200mm) | <2μm (Dimension<100mm) | |||||||||||||

| < 68% @750nm | < 23% @750nm | < 2.67% @750nm | <50μm (Dimension>200mm) | <5μm (Dimension>100mm) | |||||||||||||

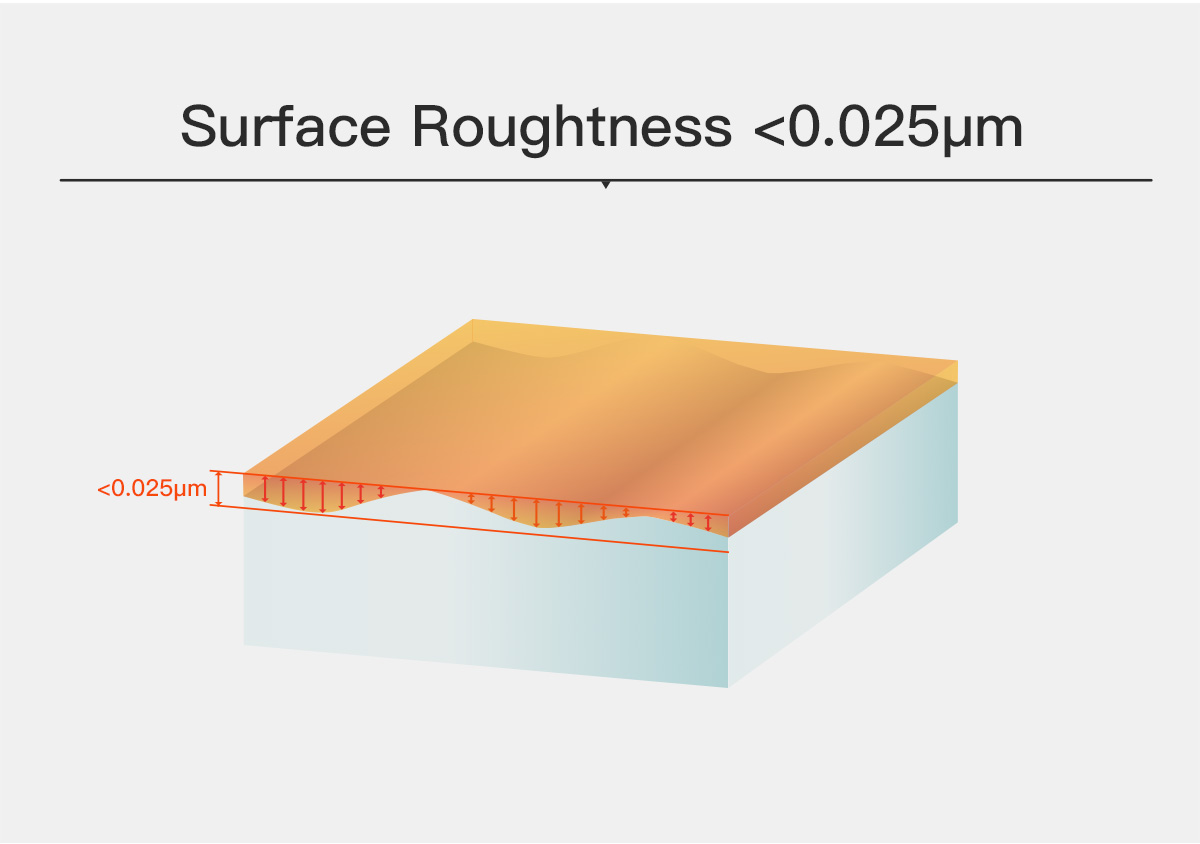

| Coating Thickness | 120nm (±0.20nm) | 100nm (±0.20nm) | 120nm (±0.20nm) | Surface Roughness | <0.025μm | ||||||||||||

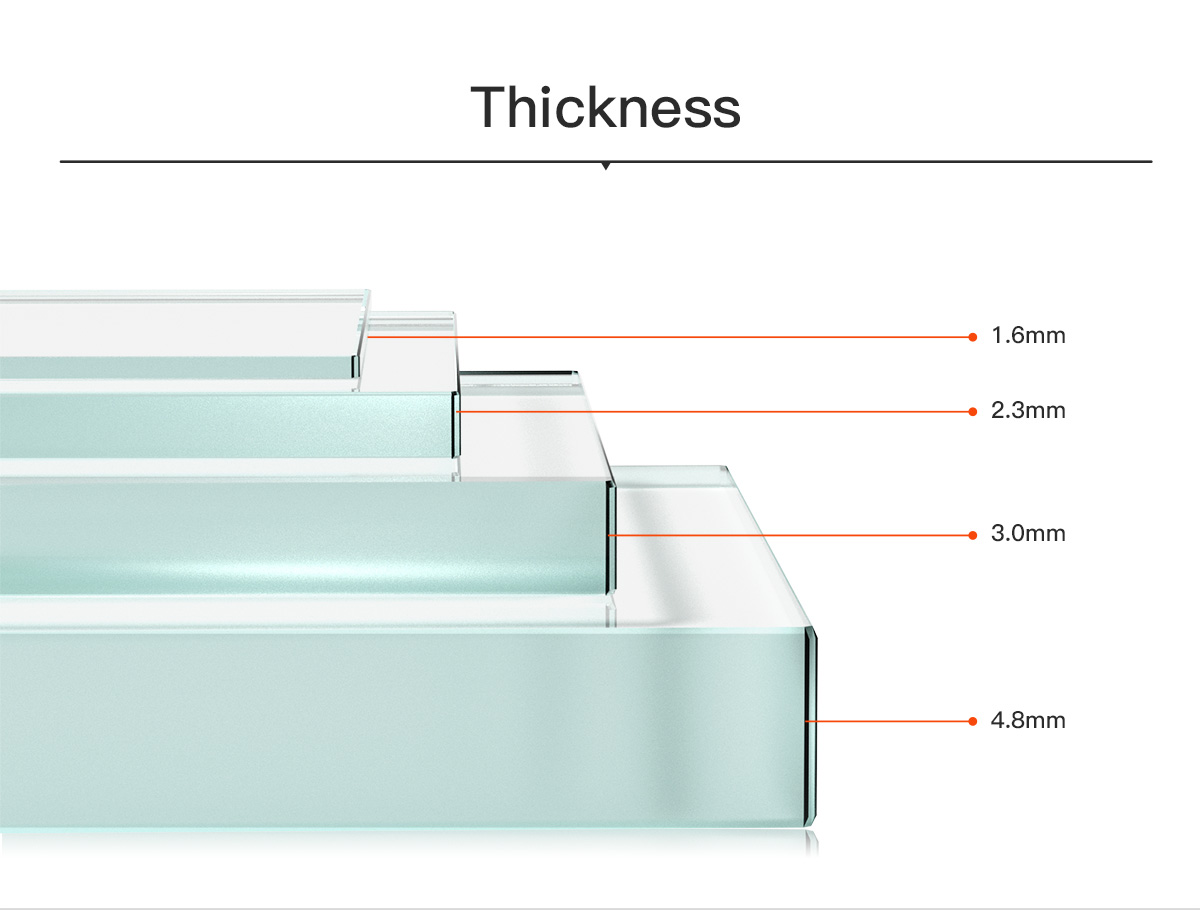

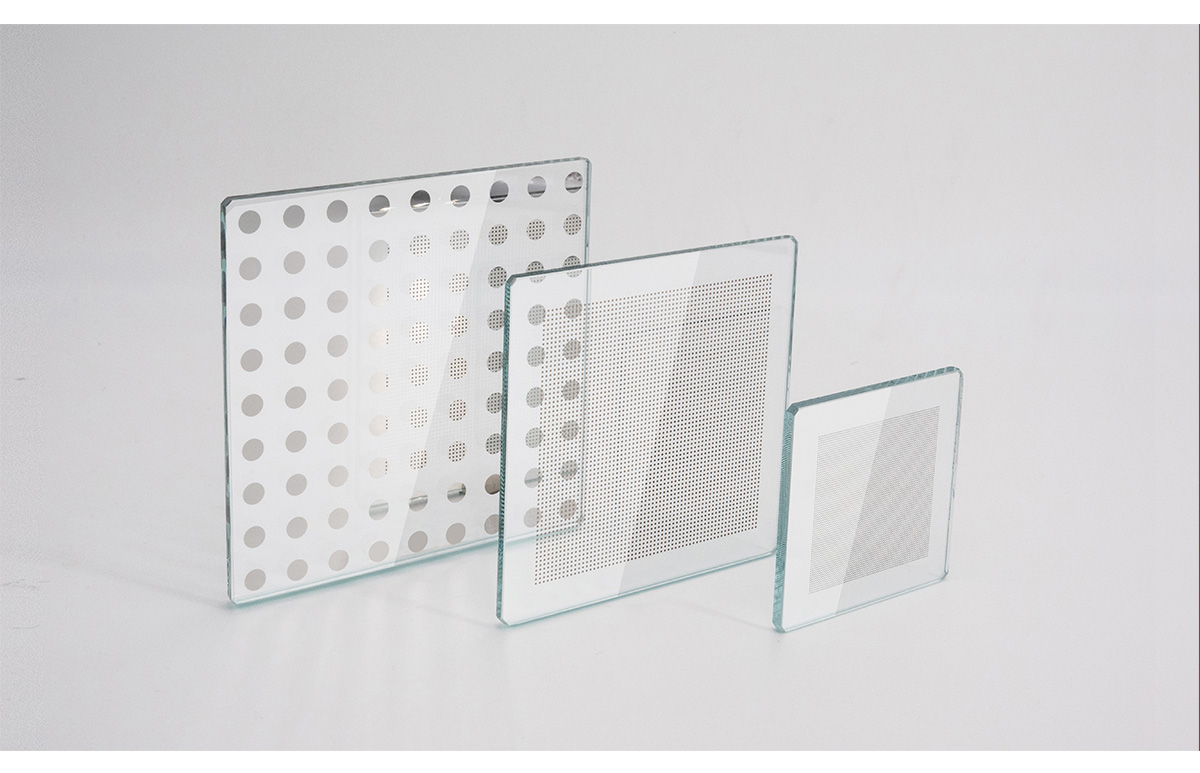

| Optical Density OD | >3 | >3 | >4.5 | Thickness | 1.6mm (±0.3mm) | 2.3mm (±0.3mm) | 3.0mm (±0.3mm) | 4.8mm (±0.3mm) | |||||||||

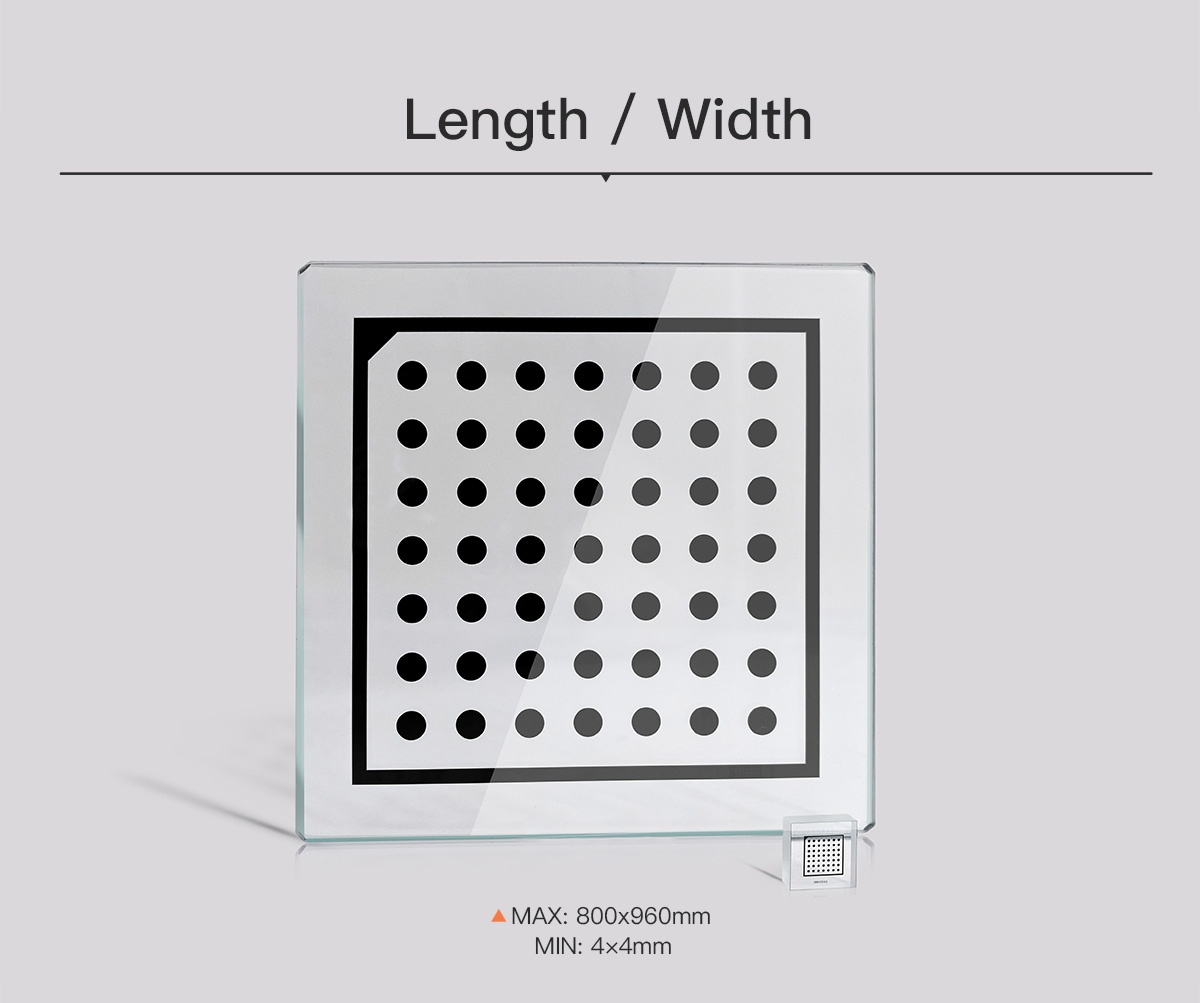

| White Background | Minimum Line/space: 10μm, Thickness: 40μm (White & Smooth Coating on the Back Side) | MIN / MAX Overall Size | MIN: 4x4mm, MAX: 800x960mm (±0.1mm) | ||||||||||||||

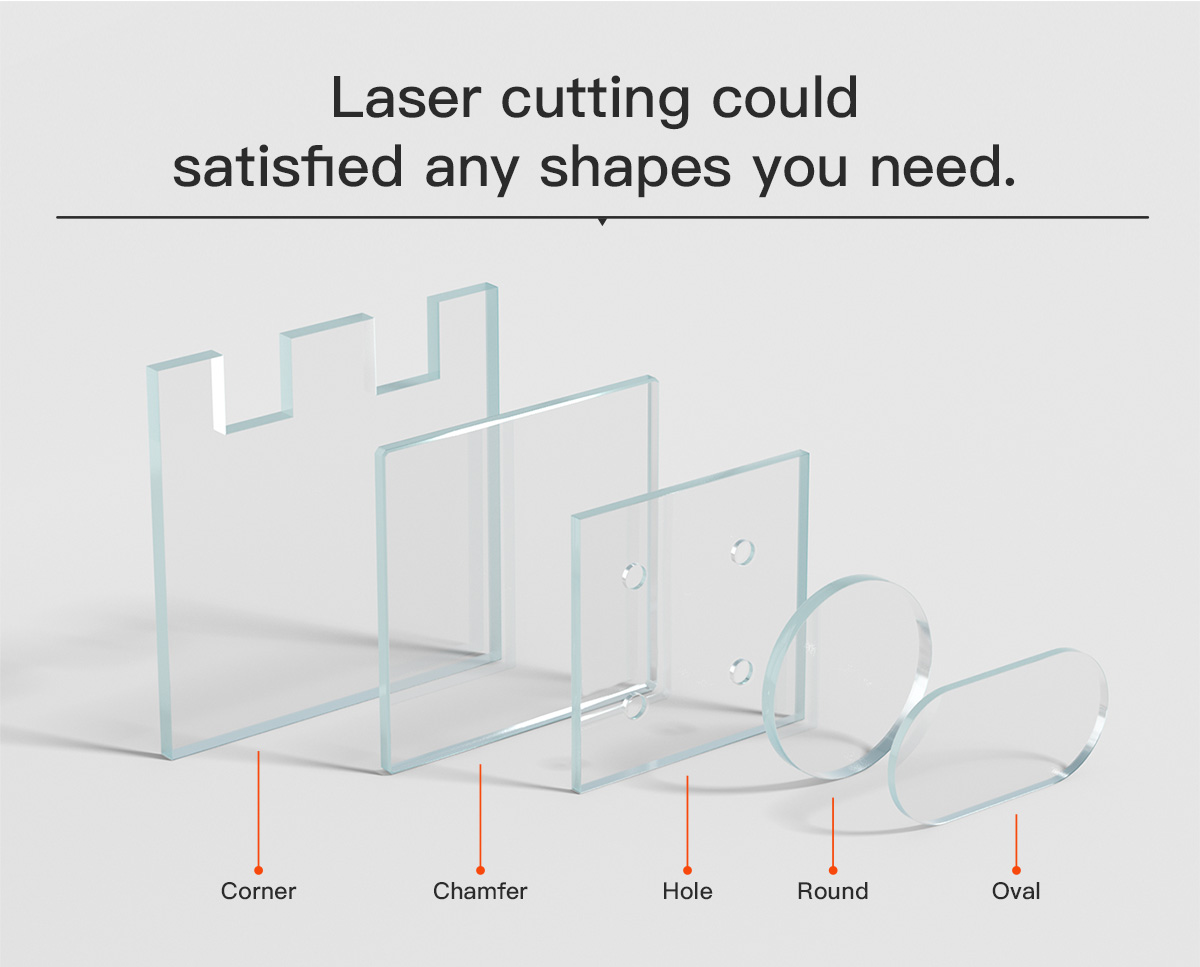

| Positive / Negative | Positive: Opaque Pattern, Clear Background. Negative: Clear Pattern, Opaque Background. | Overall Shape | Any Shape by Laser Cutting | Square | Oval | Round | |||||||||||

| Frosted Glass on the Back | Frosted glass on the back are on request. | Special-shaped | Hole | Chamfer | Angle | Corner | |||||||||||

| Custom Service | |||||||||

| Digitalize Drawing | Our engineers would help you digitize the drawing for free. | Customization Production Days | 5-10 Working Days | ||||||

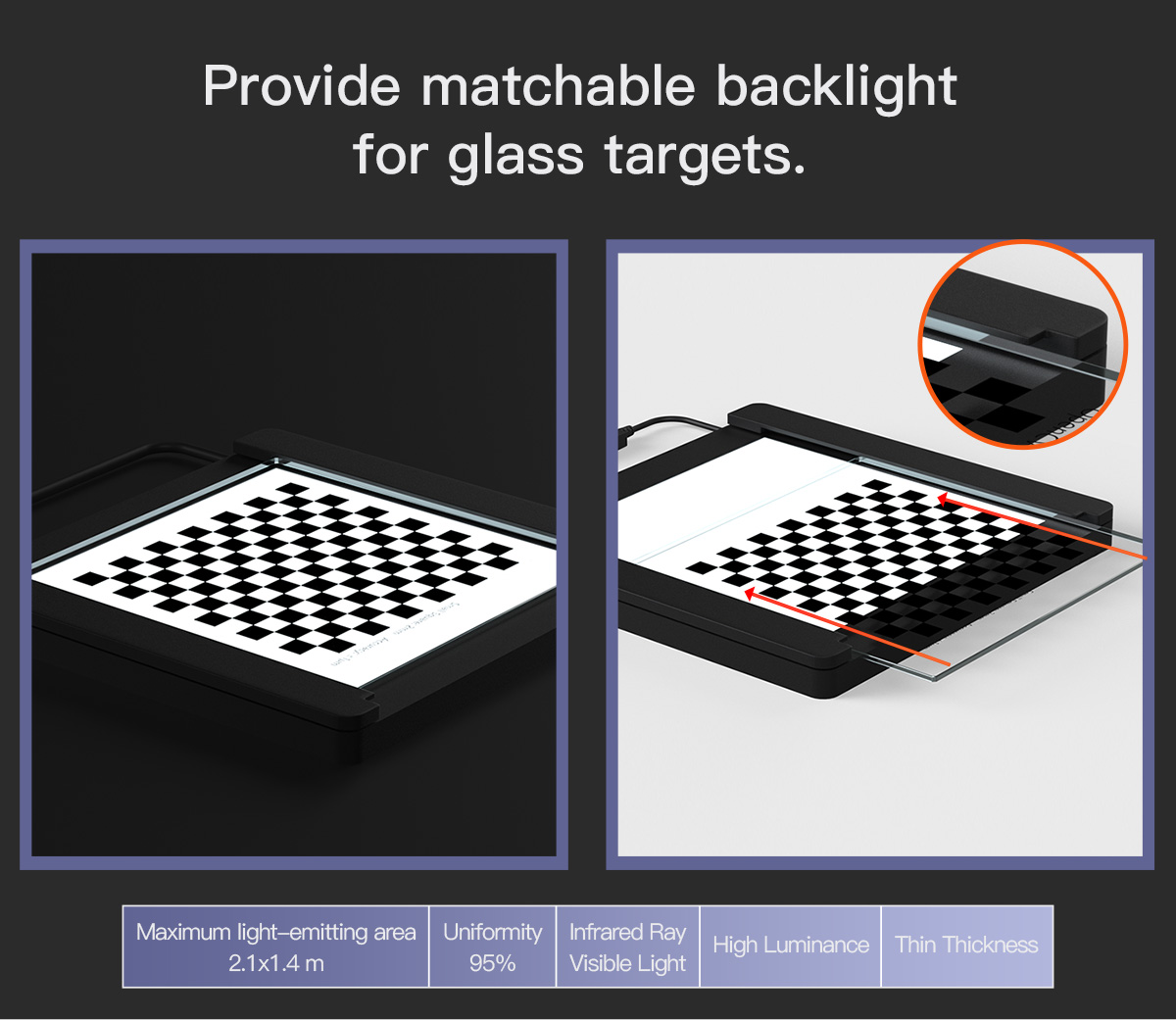

| Third Party Certification | Available | Matchable Backlight | Provide matchable backlight for glass targets. | ||||||