What is imaging?

For decades, imaging technology has been refined for industrial applications and markets, including factory automation, unmanned systems, logistics, life sciences, electronics and semiconductors, and measurement.

The reliability and consistency of imaging inspections in manufacturing also make it easy to produce high-quality commercial electronics used every day, like smartphones, PCs, and 4K TVs. This benefits consumers by enabling online purchases, saving time in shipping and delivery, and helping storage facilities and product warehouses streamline and optimize logistics processes.

These advancements have also led to an increase in the production of life-saving medications and the development of new and complex medical devices and procedures. Furthermore, this has shortened recovery time and has enabled patients to live longer, healthier lives.

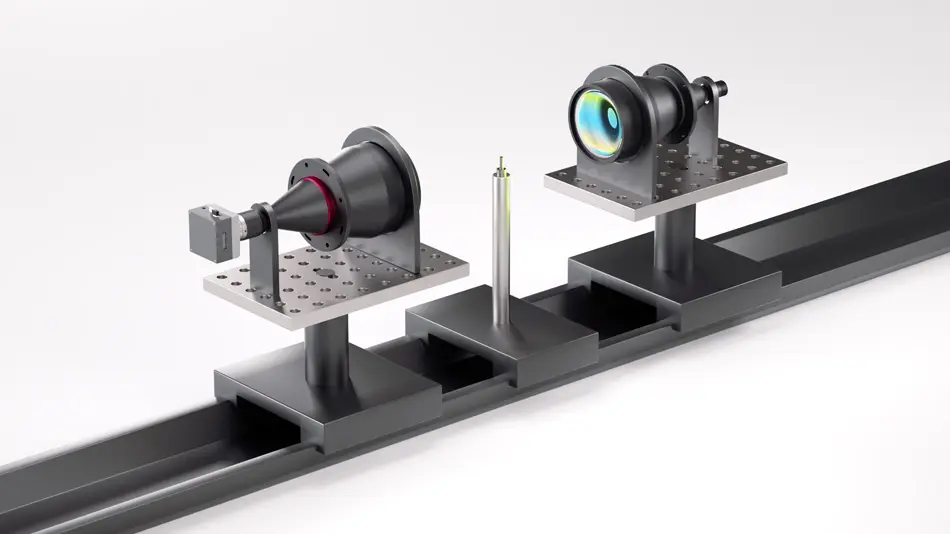

The basic components of an imaging system consist of an illumination system, an imaging lens, and a camera. The illumination system provides the necessary light to illuminate the object or feature under inspection, helping the imaging system to visualize the objects. The imaging lens captures information about the object under inspection and transfers it to the camera sensor.

The establishment of an imaging system depends on selecting the right software, motion control systems, and those three basic components. It is important to understand the characteristics of these components as decisions and trade-offs will be made for the final imaging system and its terminal application.

Methods for excellent imaging

Whether your application is in the field of machine vision, life sciences, security, or transportation solutions, understanding the basics of imaging technology can significantly simplify the development and deployment of complex imaging systems. Even with advancements in camera and illumination systems, there are still physical limitations to consider in the design and manufacture of these technologies. Optical elements, in particular, can be a critical limiting factor in system effectiveness. Therefore, this section outlines the key steps to achieving excellent imaging.

Configuration requirements

Before setting up a visual inspection system, it is important to carefully consider its spatial configuration requirements, especially for imaging systems with high resolution and magnification. This is particularly important for such imaging systems. While the technology of commercial cameras is advancing rapidly and can deliver exceptional performance in a compact design, it still does not meet the requirements of a medium-scale industrial imaging system, partly due to size restrictions.

When setting up certain devices, it’s critical to consider wiring, power, complex lighting systems, and the size of cameras and lenses. To ensure that the system works well in a given space, it’s best to plan the layout of the visual components first. Electronic and mechanical parts are usually easier to organize around the visual components. Additionally, please remember that the illumination system is part of the visual system. Because of objects’ geometry, huge illuminators, such as diffuse dome lights, are frequently required when inspecting them.

Read related post> The Four Basic Functions of Machine Vision

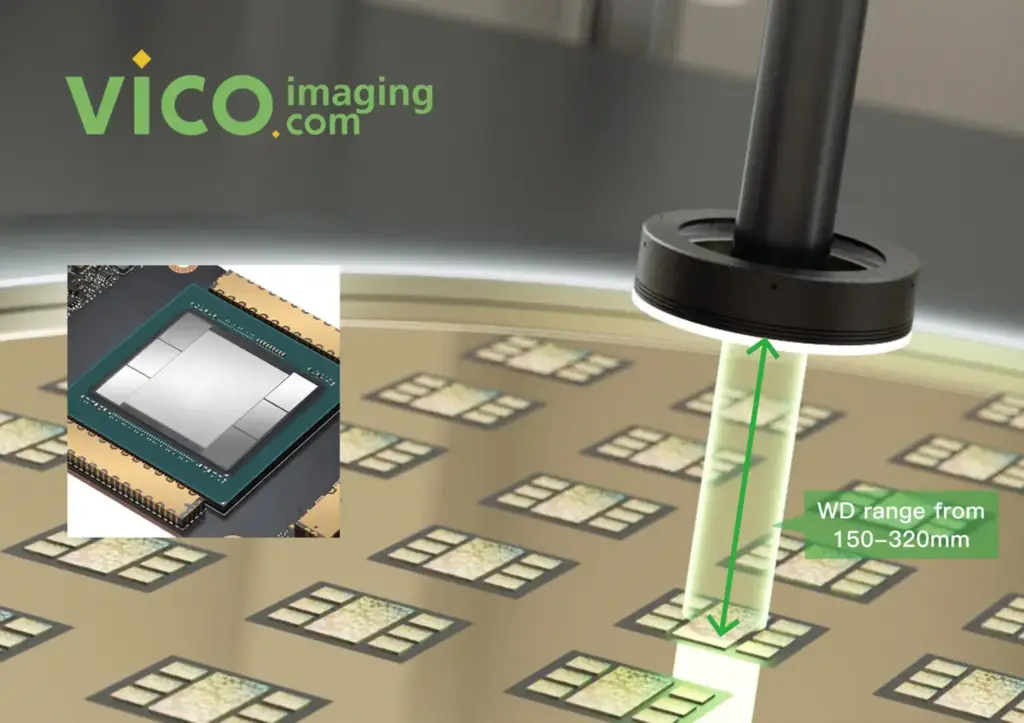

A balanced approach to FOV, WD, and sensor size

To capture high-quality images, you need to consider the relationship between the field of view (FOV) and the lens’s working distance (WD). If the FOV is too large compared to the WD, it can strain the optical components, leading to decreased system performance and increased demand for image processing. It is recommended to select a lens where the WD is roughly two to four times longer than the desired FOV width. This choice maximizes performance while minimizing cost and complexity.

This practice also applies to the relationship between sensor size and focal length. It is best to have focal length to sensor diagonal ratios of two to four (2:1 to 4:1) to maximize performance.

Read related post> WWK Series-the Ideal Choice for AOI Applications

Illumination also matters

For a lens and sensor to effectively work together, strong contrast must be reproduced by properly illuminating the object. The characteristics of the object under inspection and the nature of any defects must be understood so that the proper illumination geometry is used.

Read related post> The Significance of Telecentric System in Machine Vision

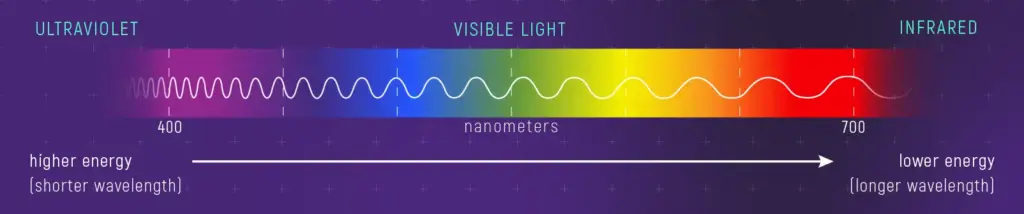

Choose the right wavelength

The wavelength (color) used for illumination can greatly impact system performance. If you’re using really good lenses and a top-notch sensor, changing from broadband to monochromatic illumination, or between specific wavelengths, it can significantly improve performance. Picking the proper wavelength is crucial for achieving good contrast and ensuring the success of the whole system.

The resolution-DOF paradox: can you have it all?

To maximize resolution and depth of field (DOF), the same variable—the f/#—must move in opposite directions. It is impossible to simultaneously have very high resolution over a large DOF. Achieving this may require more complex solutions, such as using a liquid lens or multiple imaging systems.

A one-size-fits-all solution doesn’t exist

As resolution requirements increase, the ability to decrease aberrations (attributes of optical design that adversely affect performance) becomes increasingly difficult over a wide range of operating parameters. Even without budget constraints, there are physical limitations. Therefore, a wide range of lens solutions for similar applications are required.

The importance of defining criteria for imaging

The foundation of imaging is the ability to produce the highest level of contrast on an object being inspected. This requires a deep understanding of the object’s properties, such as its materials or finishes. It’s not enough to simply know what features are considered good or bad. To ensure high levels of reliability and repeatability, it’s crucial to understand the range of details to be inspected and the criteria for determining what is good or bad.

The art of environmental control

The ability to control the environment where an imaging system is deployed significantly affects the reliability and repeatability of results. This also reduces the likelihood of potential problems. Using filters to increase contrast, baffles to eliminate unwanted light, or measurement devices to monitor light sources for stability can help control the environment. These techniques are cost-effective to protect and improve the performance of an imaging system.

Understand the fundamental parameters

By narrowing down the specific parameters required for the imaging system, the wide range of available lenses and sensors can be reduced to a manageable selection.

Imaging for application scenarios

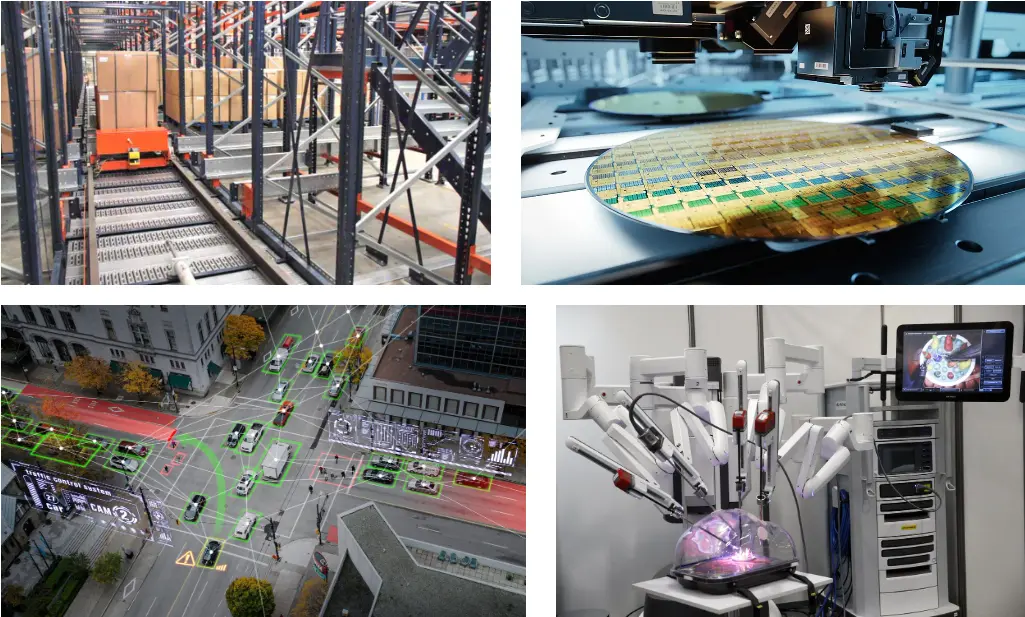

- Factory automation: The use of robotic arms, algorithms, and sensors to automatically repeat work, reducing operator monitoring. In general, automation includes classification, inspection, and defect detection. Machine vision and factory automation are closely related.

- Unmanned system: An unmanned system represents an unmanned self-control function. General unmanned systems include unmanned autonomous vehicles and trucks, flying taxis, delivery robots, and so on. Machine vision plays a crucial role in the future of unmanned systems.

- Logistics: Robots are often used in the logistics industry. They perform OCR or scan the bar code on the product, quickly identifying the products on the shelf or packages for shipment.

- Life sciences: Life sciences include biology, medicine, physiology, and so on. In addition to X-ray imaging and Magnetic Resonance Imaging (MRI), life sciences uses a wide range of imaging techniques, such as microscopic inspection of cells using special markers, classification, and so on.

- Electronics and semiconductors: More circuits can be integrated into semiconductors than in the past, requiring higher resolution in flat-panel displays. To make such complex components, electronics, and display panels must be precisely tested and defects detected using high-resolution imaging systems.

- Measurement system: For workpiece inspection, data such as features, size, or color must have consistent precision and reliable measurements. Applications requiring accurate measurements include 3D imaging and Scheimpflug scanning.

Read related post> How to Pick the Best Lens for Wafer Testing?

Conclusion

Imaging is not only the primary method for capturing and reproducing visual information about objects but also a key factor in the development of technology and industries. We can achieve more accurate and efficient imaging results by constantly improving imaging techniques such as resolution and contrast, as well as incorporating image processing algorithms. This provides vital visual support for research and applications in a variety of sectors. The widespread use of imaging technology, particularly in the pharmaceutical, semiconductor, automated manufacturing, unmanned systems, and logistics industries, has significantly boosted efficiency and accuracy, resulting in advances in intelligence and automation.