Background

Since 2020, with the development of cutting-edge materials, these factors including technological progress, increased market demand, and policy support have jointly promoted the development of industrial ruggedized lenses. The industrial ruggedized lens market is expected to continue to maintain a strong growth momentum with the further improvement of the economic environment and the continuous innovation of technology. With the advancement of the Industry 4.0 plan, embracing automated production processes seems to be a general trend, especially in the field of industrial machine vision inspection, lens ruggedization is developed to meet the requirements in various harsh environments. These conditions may include high temperature, high humidity, vibration, shock, and corrosive gases. To ensure the stability and reliability of machine vision systems in these environments, ruggedization design becomes essential.

Ruggedized lenses are lenses designed to withstand extreme or harsh environmental conditions. They are often used in industrial, military, or outdoor applications. In these applications, the lens may be damaged by physical shock, moisture, dirt, or abrasion.

The importance of ruggedized lens

Ruggedized lenses typically use specialized coatings, components, and designs to increase their durability and resistance to damage, thereby enhancing their ability to perform consistently in a variety of demanding conditions.

Classification of ruggedized lens

According to its design and functions, ruggedization design of lenses can be classified into four types.

Industrial ruggedization

Industrial ruggedized lenses are designed to survive vibration and shock, preventing damage to the lens and maintaining focus. To achieve this, we remove the lens’ moving parts and make it easier to lock, but we lose flexibility. Standard fixed focal length lenses incorporate focus mechanism and a complex iris. The typical iris consists of thin blades and ball detents to adjust f/#, which can pop out under shock and vibration. The iris is removed and a fixed aperture stop is used instead for industrial ruggedized lenses. In addition, the typical focus mechanism of a threaded barrel inside another threaded barrel is replaced by a single thread and rigid lock mechanism.

Industrial ruggedized lenses are ideal for applications where the system is once set up and no longer needs to be changed. This type of lens has additional economic advantages because it eliminates complex movement and adjustment structures, reducing the number of components required and thus saving money. Industrial ruggedized lenses are used in many applications, including high-vibration production environments, scenarios where cameras need to rapidly accelerate and decelerate, inspection systems that repeatedly perform multiple camera settings, and robotic vision.

Ingress protection ruggedization

Ingress Protection Ruggedization seals the lens assembly with an O-ring to prevent moisture and debris from entering the lens. This protection is often applied in industrial ruggedized lenses since adjustable focus and iris make sealing difficult. These lenses can be used in environments including high humidity, sputter, dust or small particles, as well as when there is no room to completely enclose the lens and camera.

Stability ruggedization

Stability ruggedization, like industrial ruggedization, protects the lens from damage while also ensuring that the optical pointing and positioning remain stable after being exposed to stress and vibration. In addition to changing the aperture and simplifying the focus mechanism, the internal components of each lens are glued to prevent them from moving in the housing.

In an imaging assembly, the lens element is located within the inner bore of the lens barrel. The distance between the outer diameter of the lens and the inner diameter of the lens barrel is typically less than 50 microns. Although the space is extremely small, an eccentricity of a few tens of microns can significantly affect the directivity of the lens. When using a lens with good stabilization, if an object point is in the center of the field of view (FOV) and rests on the precise center pixel, it will always land in the same spot, even if the lens is heavily shaken. Stability ruggedized lenses are important in applications where the FOV must be calibrated, such as measurement equipment, 3D stereo vision, lenses for robotic sensing, and lenses for tracking the location of objects. These applications often require optical pointing to be stable at all times, so that the deviation value must be much smaller than that of a single pixel.

Athermalization

Matter expands and contracts as temperature changes. The coefficient of thermal expansion (CTE) is a measure of how much a material’s dimensions change with temperature. High-performance vision systems that are subject to extreme or wide shifts of temperature changes in one dimension require athermalized imaging lenses to minimize temperature-related performance changes. Athermalization refers to the stability of an optomechanical system during extreme or varying temperatures.

Athermalization can be active or passive. Active athermalization leads to a lens that is designed and manufactured to withstand extreme or varying temperatures but may require additional adjustment mechanisms such as refocusing. Passive athermalization results in a lens that is designed and manufactured with complementary materials that do not require adjustment over a specified temperature range specification.

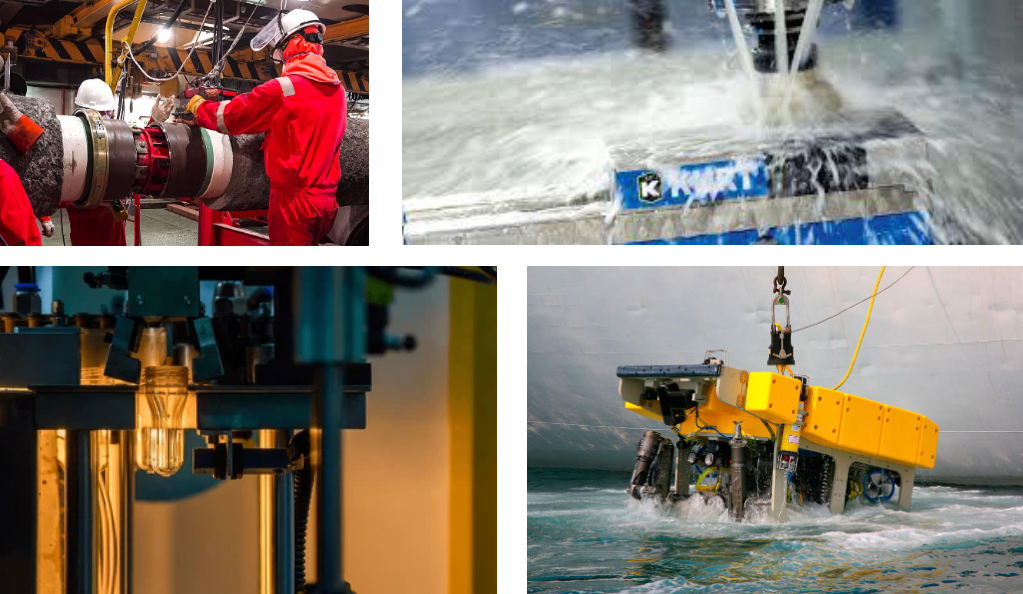

Application scenarios of ruggedized lenses

Industrial ruggedized lenses are widely used in a variety of harsh industrial environments due to their durability and high performance, such as underwater operations, high-temperature production environments, and heavy industrial production environments. These lenses are specifically ruggedized to cope with challenges such as high temperature, high humidity, strong vibration, and corrosion, ensuring the reliability and efficiency of industrial machine vision systems.

Conclusion

Lens ruggedization plays a key role in the field of industrial machine vision inspection. Different ruggedization designs can effectively respond to various environmental challenges and improve the stability and reliability of the system. However, these designs may also cause problems such as increased volume, weight, and cost. Therefore, when selecting a ruggedization design, it is necessary to consider the specific application environment, cost-effectiveness, and long-term maintenance needs. With the continuous advancement of technology, future ruggedization designs will be more intelligent and efficient, providing a more comprehensive solution for industrial vision inspection.

Read related post> The Four Major Elements Of Domestic Machine Vision Technology