Define machine vision

Machine vision is a technology that enables computers to see and interpret data including images and video. In automation manufacturing, it plays a pivotal role in enhancing efficiency, quality, and precision.

Read related post> The Four Basic Functions of Machine Vision

The relationship between machine vision and automation manufacturing

Machine vision is crucial to automation manufacturing, enabling precise inspection, quality control, and guidance for robotic systems. It enhances efficiency by quickly detecting defects, ensuring accuracy, and reducing the need for manual intervention. This integration of machine vision with automation drives higher productivity and consistent product quality.

Integrating machine vision into automation manufacturing systems

Quality control:

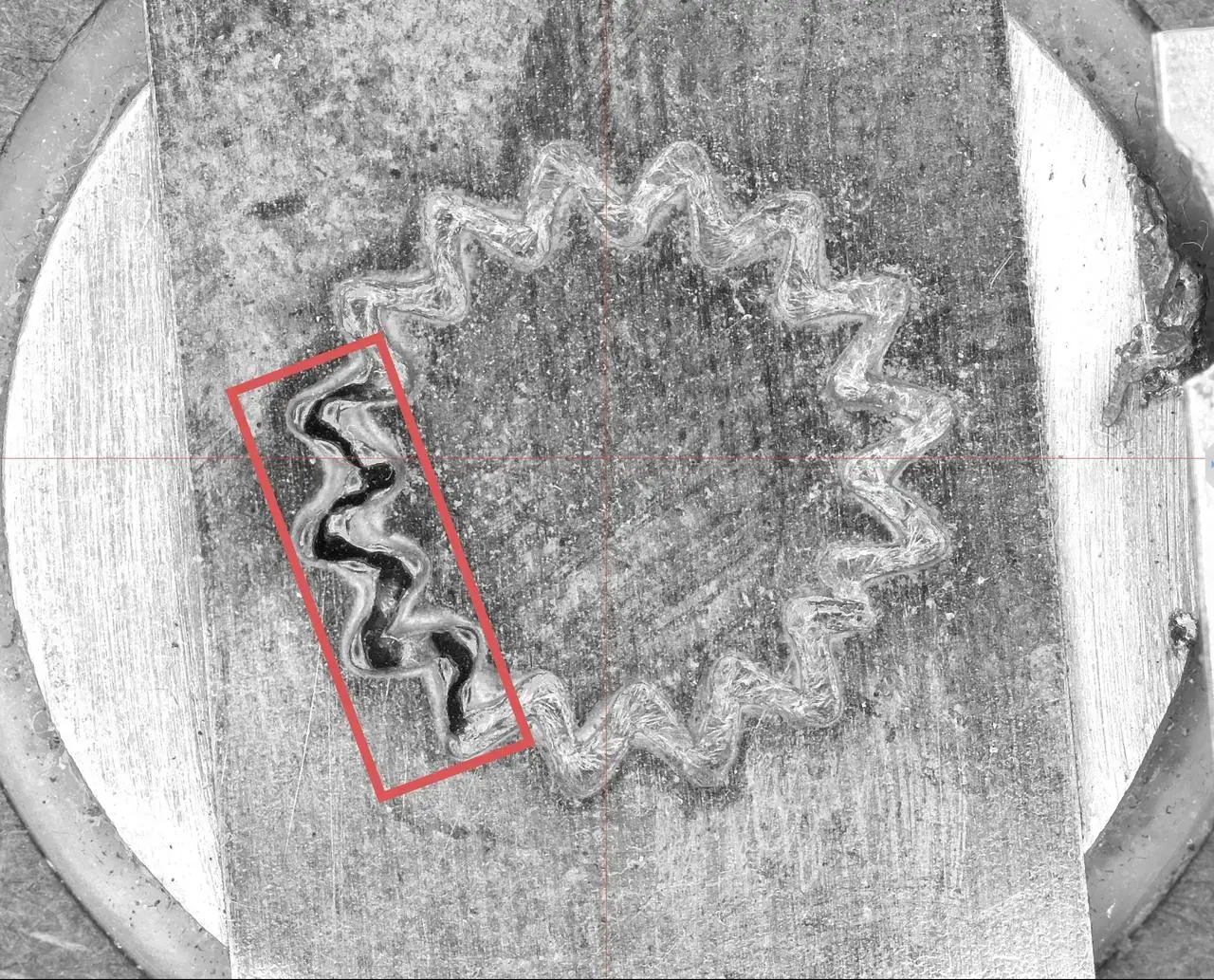

- Defect inspection: Machine vision systems can inspect products for defects such as scratches, cracks, or missing parts, ensuring that only high-quality products reach the market.

- Dimension measurement: By measuring dimensions and tolerances, machine vision helps maintain product consistency and compliance with standards.

Assembly guidance:

- Component identification: Machine vision can accurately identify and locate components on a conveyor belt or in a bin, facilitating automated assembly processes.

- Position inspection: It can ensure that components are correctly positioned before being assembled, preventing errors and rework.

Robotics control:

- Object tracking: Machine vision assists robots in tracking the movement of objects, enabling them to perform tasks like picking, placing, and packaging with precision.

- Collision avoidance: By detecting obstacles, machine vision helps robots avoid collisions and ensure safe operation.

Inventory management:

- Barcode and QR code reading: Machine vision can read barcodes and QR codes on products, enabling automated inventory tracking and management.

- Counting and sorting: It can count and sort items based on their appearance, facilitating efficient warehouse operations.

Cases of industries that rely on machine vision and automation manufacturing

Automotive industry

The lithium-ion battery industry is booming, due to the rapid growth of markets such as new-energy vehicles, portable electronic devices, etc. In the meantime, lithium battery companies are increasing R&D investment, driving continuous improvement in materials, techniques, and battery management systems.

The lithium-ion battery industry is booming, due to the rapid growth of markets such as new-energy vehicles, portable electronic devices, etc. In the meantime, lithium battery companies are increasing R&D investment, driving continuous improvement in materials, techniques, and battery management systems.

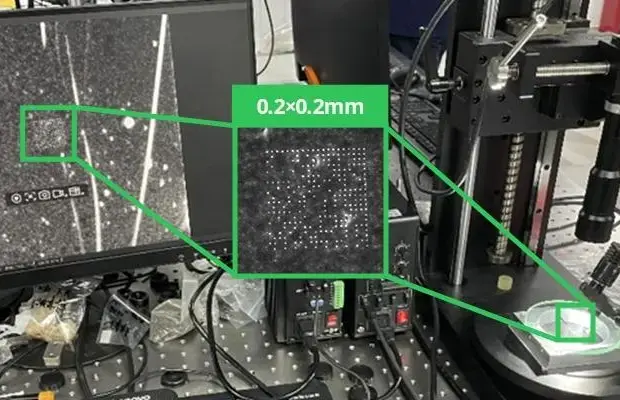

However, in the production of lithium batteries, problems at any step may lead to various defects, thus affecting the batteries’ quality. Therefore, machine vision plays a crucial role. It uses high-precision optical imaging technology and advanced image processing algorithms to inspect various stages of lithium battery production, such as dimension measurement, cosmetic inspection, alignment inspection, and code reading, to ensure the high quality and good performance of the battery.

Adopting an ideal machine vision system not only improves inspection efficiency but also ensures the reliability of the inspection results, meeting the strict requirements of the industrial field for high-quality inspection standards.

Read related post> Vision Stuttgart 2024: Experience VICO Imaging’s Cutting-Edge Solutions for Li-ion Battery and PCBA Inspections

Electronics industry

Many electronic devices rely on a tiny computer chip called Semiconductor. Be it computers, laptops, mobile phones, washing machines, and even cars. However, the inspection of essential chips is quite challenging. Manufacturers try to create small components without feature shrinkage. As a result, their designs become more complicated, affecting the inspection process.

Many electronic devices rely on a tiny computer chip called Semiconductor. Be it computers, laptops, mobile phones, washing machines, and even cars. However, the inspection of essential chips is quite challenging. Manufacturers try to create small components without feature shrinkage. As a result, their designs become more complicated, affecting the inspection process.

With an advanced machine vision system, spotting defects at every production stage becomes easier. Machine vision assists in locating and mapping any existing defects. Besides, it helps while separating them from potential IC manufacturing process flaws. In doing so, the system helps to ensure wafers are free of defects before production begins.

Read related post> 24K Linescan Bi-Telecentric Lenses: Unlocking New Levels of Precision for Wafer Inspection!

Pharmaceutical industry

In liquid pharmaceutical inspection, for instance, machine vision is used, in combination with telecentric lenses. They produce images of the inspected medical bottles and then analyze the images to detect any defects or contaminants. Besides, a machine vision system, coupled with lenses, can contribute more to pharmaceutical inspection. In the label inspection process, it helps to inspect the labels on containers, ensuring that the labels are properly aligned. This procedure is fast and reliable, making it ideal for high-volume production lines in this industry.

In liquid pharmaceutical inspection, for instance, machine vision is used, in combination with telecentric lenses. They produce images of the inspected medical bottles and then analyze the images to detect any defects or contaminants. Besides, a machine vision system, coupled with lenses, can contribute more to pharmaceutical inspection. In the label inspection process, it helps to inspect the labels on containers, ensuring that the labels are properly aligned. This procedure is fast and reliable, making it ideal for high-volume production lines in this industry.

Read related post> How Telecentric Lenses Are Used for Liquid Pharmaceutical Inspection

Benefits of machine vision and automation manufacturing

Safe inspection: In the past, people have to place themselves in dangerous conditions to perform their tasks. With the involvement of machine vision and automation manufacturing, fewer people are facing such danger.

Increased productivity: Automation systems can operate at higher speeds than manual processes, which leads to significantly increased output. Machine vision inspects defects and inconsistencies to prevent rework. These machines can operate continuously, maximizing production time. All these properties of machine vision and automation manufacturing contribute to increased productivity.

Reduced costs: Automation reduces labor needs, lowering labor costs. Machine vision can reduce waste and scrap rates in a variety of ways, including detecting manufacturing flaws, identifying overfill, and pinpointing the causes of defects. This can eventually help control overhead and reduce raw material costs.

Real-time data collection: Automation systems generate vast amounts of data that can be analyzed to identify trends, optimize processes, and improve decision-making. After data collection, the system gives instant feedback for optimization by analyzing data collected previously. Then manufacturers can locate areas for improvement and optimize their production lines.

Conclusion

Discover how our machine vision inspection systems can transform your production line into a pinnacle of quality and efficiency. We offer visual inspection solutions across various industries, including automotive, aerospace, consumer goods, medical, pharmaceutical, packaging, etc.

Every machine vision application is unique, and our experts work with customers to gather all the requirements and specific needs. Solutions are then tailored to meet the application needs and provide the best outcomes. Choosing VICO Imaging is choosing a promising future for your automation manufacturing.