What is an achromatic design?

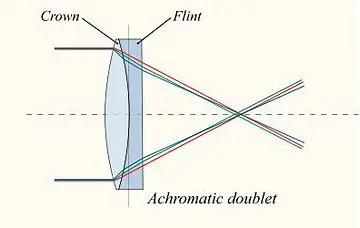

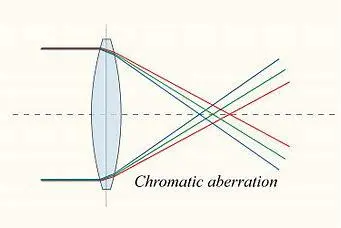

Chromatic aberration refers to the phenomenon where different wavelengths of light passing through the lens produce different refractive indices and dispersion during the imaging process, resulting in color distortion at the edges of the image. This phenomenon will reduce the clarity and color reproduction accuracy of the image, affecting the overall imaging quality. Achromatic lenses or apochromatic lenses are lenses designed to minimize chromatic aberration and spherical aberration.

The common form of achromatic lenses is achromat doublets. These two lenses are made of two types of glass with different dispersion abilities. They are bonded by two optical components, a positive low refractive index (crown) and a negative high refractive index (flint). When the optical magnification of the positive lens of the crown glass is not canceled out by the negative lens of the flint glass, their combination can focus light of different wavelengths together on a focal point with a longer focal length. Achromatic lenses allow two different wavelengths of light to converge in the same plane.

Types of industrial lenses with achromatic design

Achromatic objective

Achromatic objectives are a common type of microscope objective. It consists of several sets of positive and negative glued lenses with different curvature radii, which can only correct the axial chromatic aberration of red and blue light in the spectral line as well as the axial point spherical aberration and the paraxial point comatic aberration. This objective lens cannot eliminate the secondary spectrum, and the field of view is greatly curved. In other words, only clear images in the middle range of the field of view can be obtained.

This type of objective lens is simply structured, economical, and widely used in medium- and low-end microscopes.

Semi-apochromatic objective

Semi-apochromatic objectives are partially made of fluorite, so they are also called fluorite objectives. In terms of structure, they have more lenses than achromatic objectives and fewer than apochromatic objectives. They have better performance than achromatic objectives and are cheaper than apochromatic objectives.

Apochromatic objective

Achromatic lenses are lenses or other lenses that have better chromatic correction performance than general achromatic lenses. As previously mentioned, chromatic aberration is the phenomenon where different colors of light converge on different focal lengths after passing through the lens. In photography, it causes the overall hue of the image to become softer, and the contrast of color edges is reduced, such as the edge between black and white. Simply put, this objective lens corrects the axial chromatic aberration of red, blue, and yellow light, eliminates the secondary spectrum, and therefore has high imaging quality.

Read related post> Vision Stuttgart 2024: Experience VICO Imaging’s Cutting-Edge Solutions for Li-ion Battery and PCBA Inspections

The differences among achromatic, semi-apochromatic, and apochromatic objectives

Achromatic or flat-field achromatic objectives can at least correct the axial chromatic aberration of points on the axis (red and blue), spherical aberration (yellow-green light), sinusoidal aberration, and eliminate near-axis point coma. However, under green and white light, using achromatic objectives can achieve better imaging results, although not the best results.

Achromatic or flat-field achromatic objectives can at least correct the axial chromatic aberration of points on the axis (red and blue), spherical aberration (yellow-green light), sinusoidal aberration, and eliminate near-axis point coma. However, under green and white light, using achromatic objectives can achieve better imaging results, although not the best results.

Semi-apochromatic or flat-field semi-apochromatic objectives can correct the spherical aberration and chromatic aberration of red and blue colors. Its imaging quality is much higher than that of apochromatic objectives. In color microscopic imaging, a semi-apochromatic objective is the most cost-effective option.

The apochromatic or flat-field apochromatic objective lens can not only correct the chromatic aberration of red, green, and blue light but also the image on the same focal plane, achieving the effect of eliminating secondary chromatography (residual chromatic aberration) and correcting the spherical aberration of red and blue light. It has a larger numerical aperture, higher resolution, better imaging quality, and higher magnification. Overall, the performance of apochromatic objectives is excellent, and the depth of field is smaller than other objective lenses, so the price is higher.

Benefits of apochromatic lenses in factory automation

Excellent color reproduction: By using aspherical lenses, the aberration of light can be reduced, allowing more accurate focusing. The apochromatic lens can focus three wavelengths of light (usually red, green, and blue) at the same point, thereby minimizing chromatic aberration. This contributes to capturing true colors.

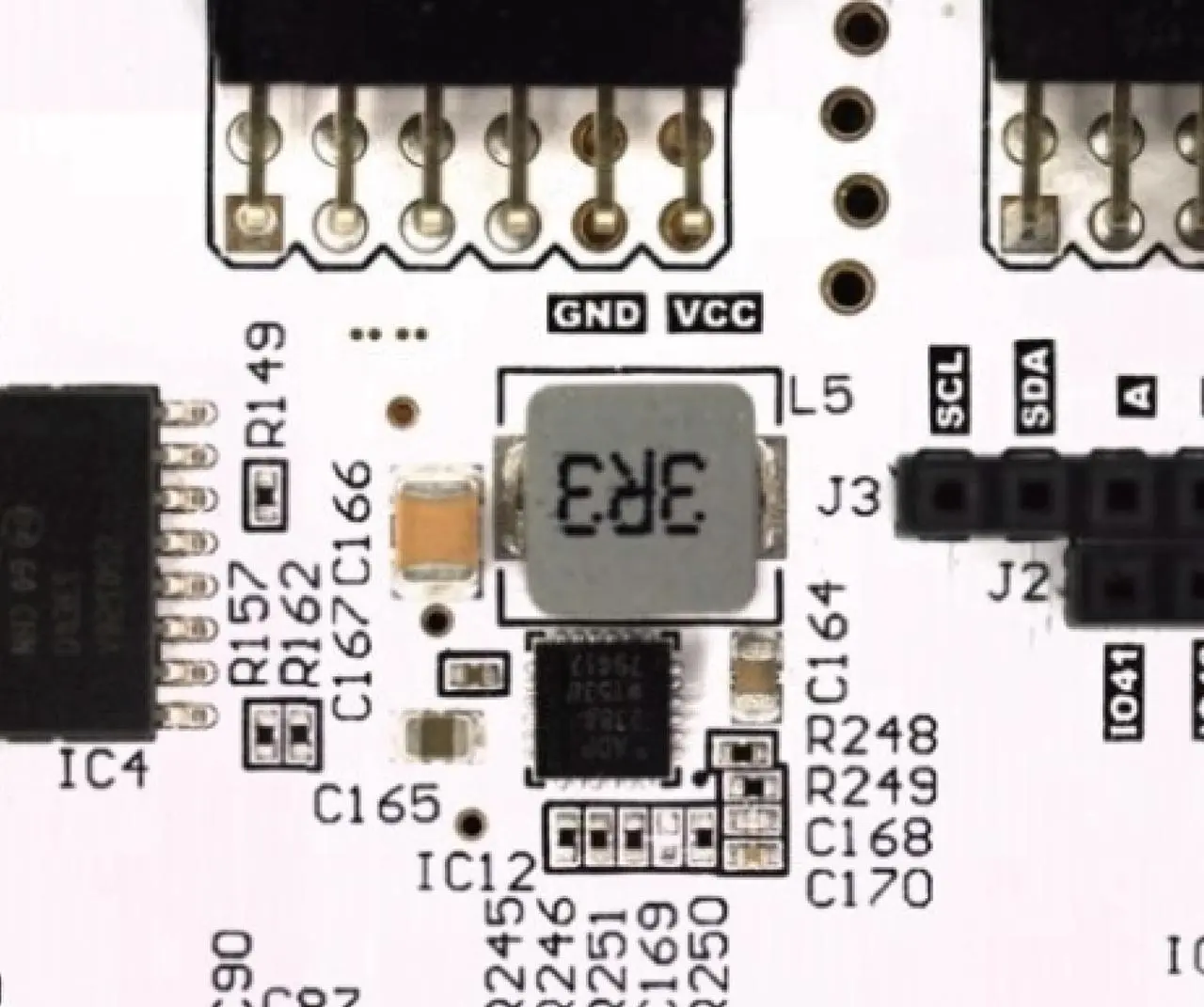

High-resolution imaging: The design of the apochromatic lens significantly reduces dispersion effects by using low-dispersion glass materials and multi-layer coating technology, further improving image clarity and ensuring excellent imaging results under various conditions. This is crucial in inspecting details of precise components, especially in the applications of PCBA, automobiles, and the semiconductor industry.

Higher measurement accuracy: A high parallel level of light path lowers distortion, and therefore improves measurement accuracy, ensuring reliable and repeatable results. This is quite important in applications requiring strict quality control.

Outstanding performance: Special light path design guarantees consistent imaging clarity even if visible light of various wavelengths is shifted. Using different colors of light can eliminate the need for subsequent focusing and therefore improve efficiency.

Long-term cost-effectiveness: Although achromatic lenses are more expensive than standard lenses, they can provide higher accuracy, reduce errors in automated processes, improve pass rate, and reduce long-term operation costs.

Case study: Why do we choose COOLENS® apochromatic lenses for PCBA inspection?

Our COOLENS®DTCA 3D AOI series minimizes chromatic aberration through RGB confocal design. When inspecting components at different heights on the PCBA, this series uses different colors of light without subsequent focusing, and can collect 3D information of the inspected object, which is convenient for computer 3D simulation. This series of lenses not only has an apochromatic design, but also is bi-telecentric. Coupled with high resolution, its light path is highly parallel, resulting in extremely low distortion, so it can achieve shadow-free, low distortion, and high-precision images, accurately identifying defects and measuring dimensions.

Factors to consider when choosing lenses with achromatic design

Focal length: The focal length determines the field of view of the lens. The longer the focal length, the smaller the field of view of the lens, and the smaller the range that can be imaged, but it can enlarge distant objects, having them imaged larger and clearer. At the same time, using different colors of light can avoid subsequent focusing, shortening steps, and saving time.

Resolution: The resolution of the lens determines the clarity of its image. High-resolution lenses can capture more details, which is crucial for automated optical inspection systems that require precise measurements.

Aperture: The aperture size affects the amount of light entering and the depth of field of the lens. In automated optical inspection, the appropriate aperture needs to be selected according to the lighting conditions and inspection accuracy requirements. A larger aperture can provide more light entering, but the depth of field is shallower; a smaller aperture has a larger depth of field but may require a stronger light source.

Achromatic performance: This is the core factor in choosing a chromatic aberration design lens. It is necessary to ensure that the lens has excellent chromatic aberration correction ability to reduce or eliminate color edges and color distortion caused by differences in the refraction of light at different wavelengths and improve the accuracy of detection results.

Costs: Consider the cost-effectiveness of the lens while meeting the inspection needs. Compare the performance, price, and service of different brands and models of lenses to choose the most suitable lens for automated optical inspection systems.

Conclusion

Industrial lenses with achromatic design are a milestone in the development of optical technology. Since their invention in the 19th century, achromatic lenses have largely improved the accuracy and quality of optical imaging by correcting the focus differences of different wavelengths of light. This breakthrough has enabled the development of fields such as machine vision, microscopic imaging, and automated inspection, achieving high-precision and chromatic-free image capture. With the advancement of Industry 4.0, the future of achromatic lens application is promising. In the future, they will play a key role in more complex intelligent manufacturing and automation systems. Chromatic lenses not only carry the glorious history of optical development but will also continue to lead the progress of precision imaging in future technological changes. Explore new possibilities in optical technology together with VICO Imaging!