What is imaging quality?

Imaging quality pertains to the sharpness, level of detail, and reproduction of a visual image. Its evaluation usually depends on multiple factors, including resolution, contrast, color reproduction, and distortion. Imaging quality reflects the ability of the optical system to capture and reproduce scene details, which significantly impacts user experience and application effects. In optical design, optimizing imaging quality often requires comprehensive consideration of the design of optical components, material properties, and light ray configuration to ensure that the final image achieves the ideal visual effect.

Imaging quality pertains to the sharpness, level of detail, and reproduction of a visual image. Its evaluation usually depends on multiple factors, including resolution, contrast, color reproduction, and distortion. Imaging quality reflects the ability of the optical system to capture and reproduce scene details, which significantly impacts user experience and application effects. In optical design, optimizing imaging quality often requires comprehensive consideration of the design of optical components, material properties, and light ray configuration to ensure that the final image achieves the ideal visual effect.

Imaging quality is crucial in automated optical inspection (AOI) in industrial automation, as it directly affects the accuracy and efficiency of inspection. High-quality images can present the details of the inspected object, enabling the system to effectively identify minor defects, improve product qualification rates, and reduce rework. At the same time, it ensures consistent results under different conditions, enhancing system reliability. By improving imaging quality, the AOI system can not only accelerate image processing speed but also achieve more efficient real-time inspection.

Modulation Transfer Function and distortion play a key role in high-quality imaging. MTF measures the performance of the optical system to analyze details and is a key indicator for judging image clarity and sharpness; while distortion describes the degree of distortion of the image geometry, which may lead to detail distortion. High MTF values mean that the image can more accurately reproduce the original scene, while low distortion ensures the true presentation of the image. Only when both are optimized can high-quality imaging be achieved, ensuring that the image is both clear and accurate in applications such as industry and medicine, meeting various precise inspection and analysis needs.

Read related post> A Definitive Guide to Automated Optical Inspection (AOI) in 2024

Understanding MTF

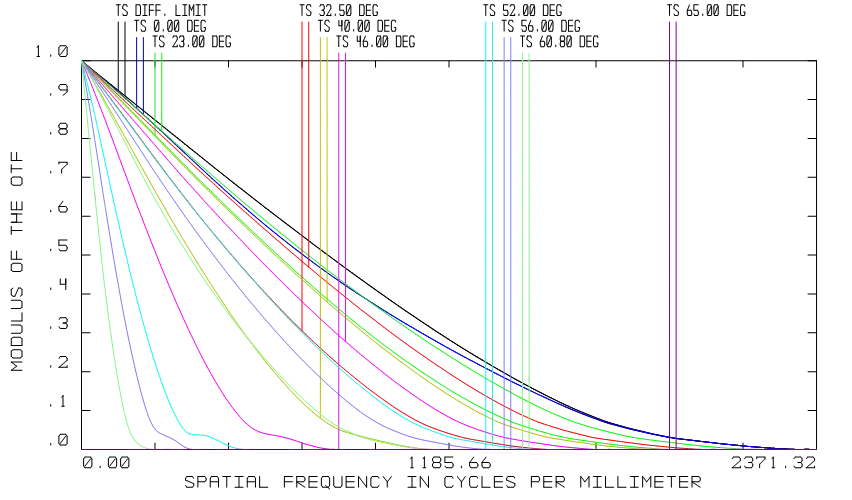

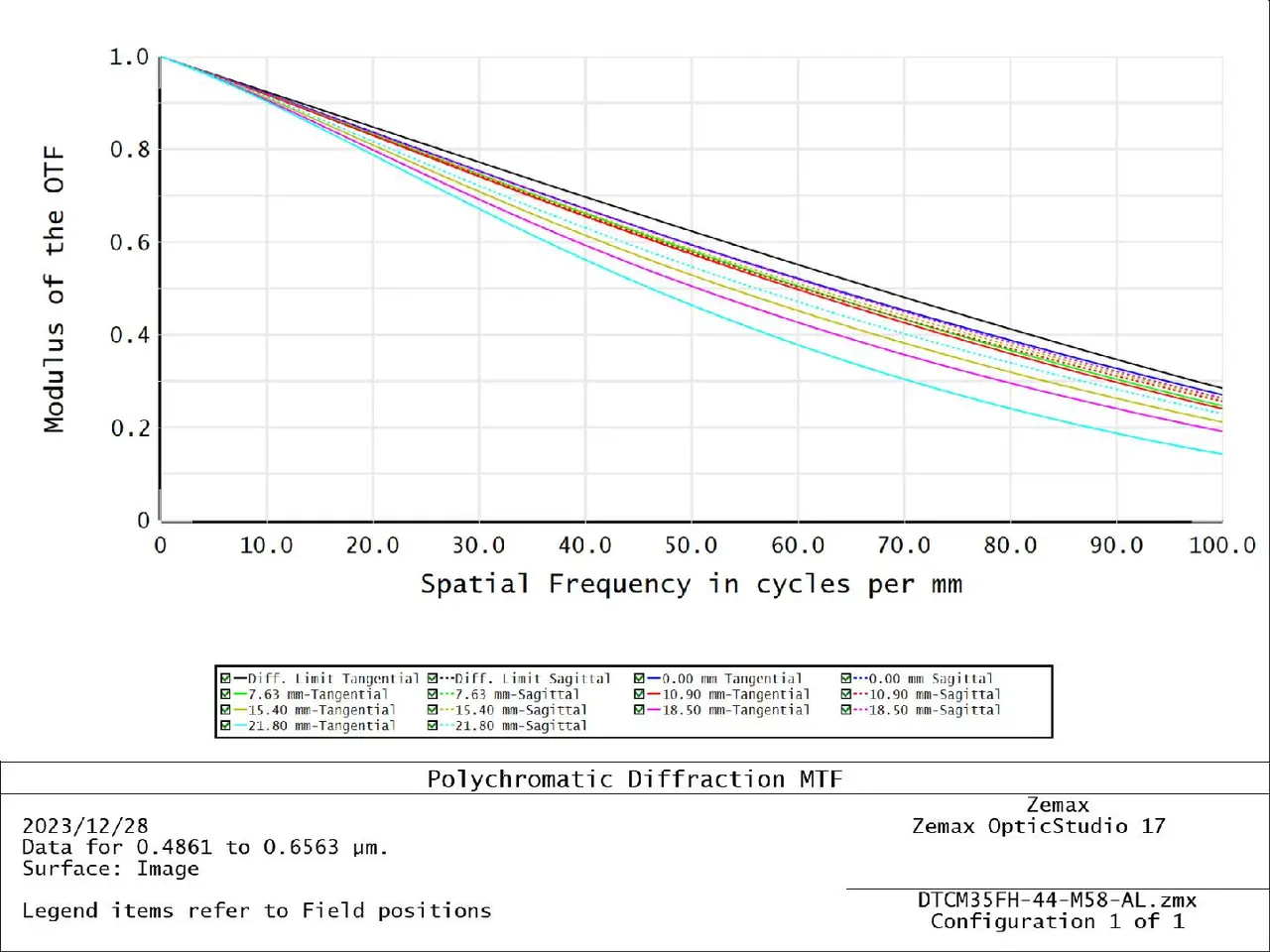

The modulation transfer function (MTF) curve is an information-intensive indicator that reflects how the lens reproduces contrast when the spatial frequency (resolution) changes. These curves comprehensively summarize how optical aberrations affect performance under specific basic parameter combinations that are determined according to application requirements. Changing almost any setting on the visual system (including basic parameters) will change the performance features of the curve.

The modulation transfer function (MTF) curve is an information-intensive indicator that reflects how the lens reproduces contrast when the spatial frequency (resolution) changes. These curves comprehensively summarize how optical aberrations affect performance under specific basic parameter combinations that are determined according to application requirements. Changing almost any setting on the visual system (including basic parameters) will change the performance features of the curve.

The MTF curve displays both resolution and contrast, reviews lenses based on specific application features, and is used to compare the performance among multiple lenses. If used properly, the MTF curve can help determine whether the application is feasible.

Specifically, MTF measures image clarity and sharpness by analyzing the contrast transfer at different spatial frequencies. Its calculation is based on the ratio of the contrast of the object image to its corresponding frequency, which can reveal the performance of the optical system at different detail scales. High MTF values indicate that the optical system can effectively reproduce details, especially in high frequency (i.e. Information-intensive areas). In contrast, low MTF values mean that the image may be blurred or distorted. Therefore, MTF provides an important quantitative basis for designing and optimizing optical systems, ensuring they can achieve the required imaging quality in practical applications.

Types of distortion in imaging

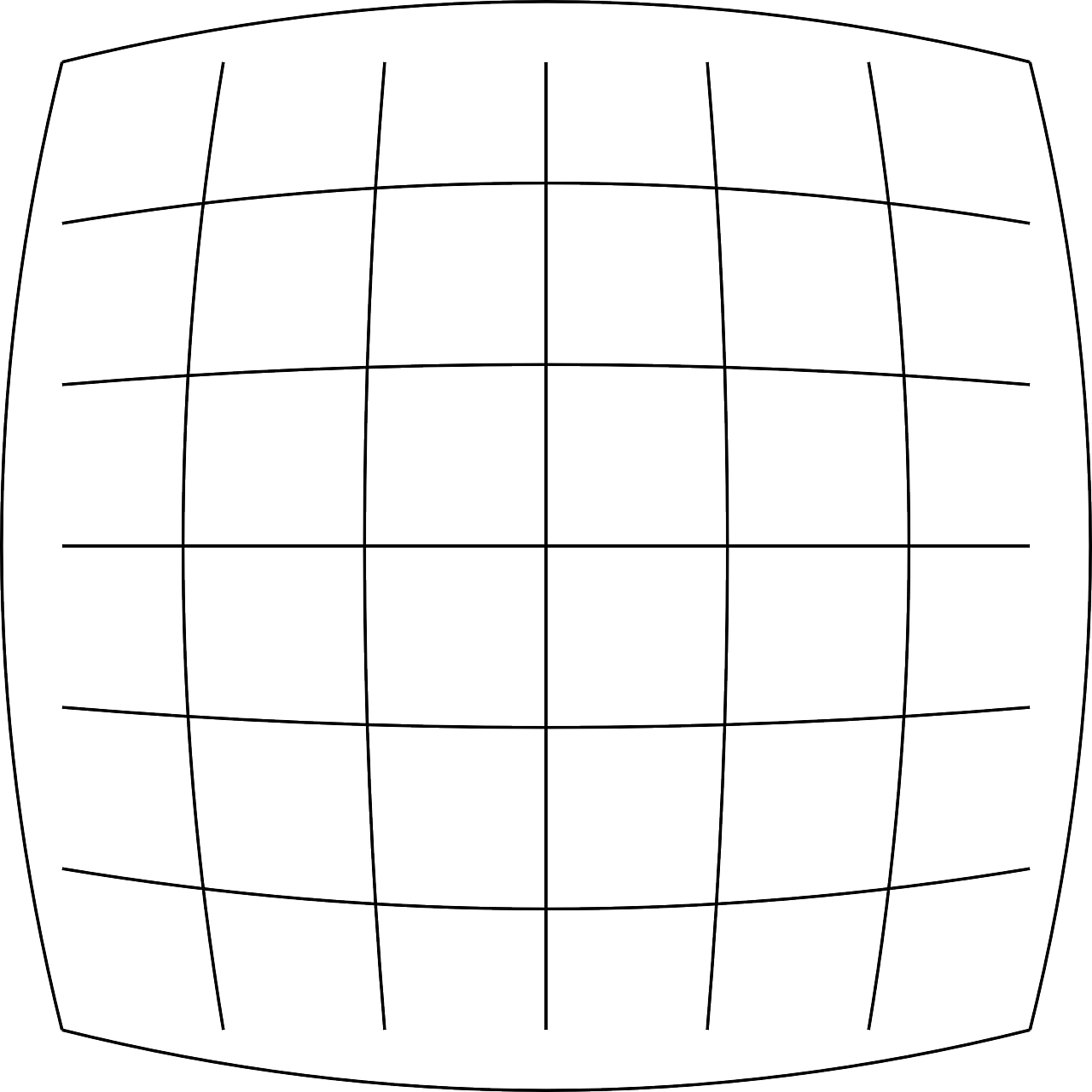

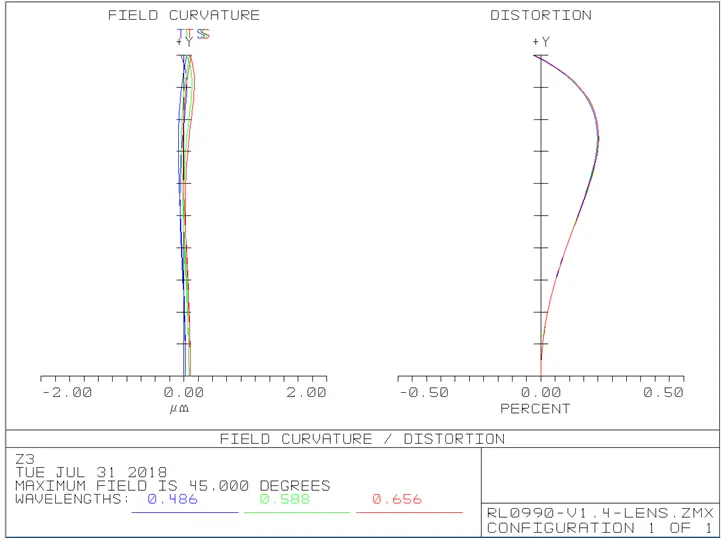

In imaging systems, distortion can cause the optical magnification to change with the position of the field of view. Distortion is the distortion of the geometric shape of the image by the optical system during the imaging process, resulting in shape distortion between the image and the original object, thereby affecting the accuracy of details and the reproduction of the image. It not only reduces the accuracy of the image but may also affect subsequent image analysis and processing, especially in applications of precise inspection and measurement.

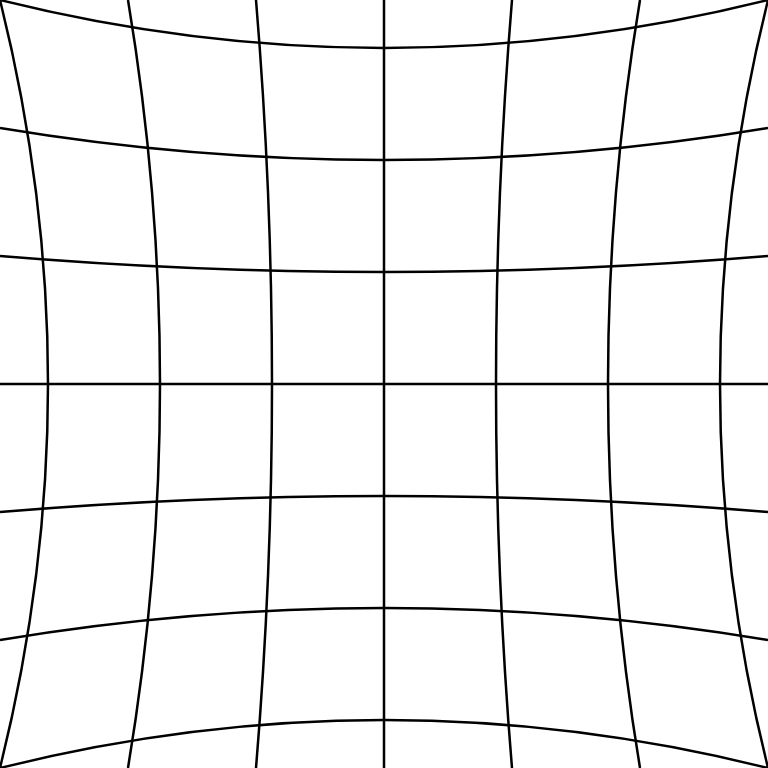

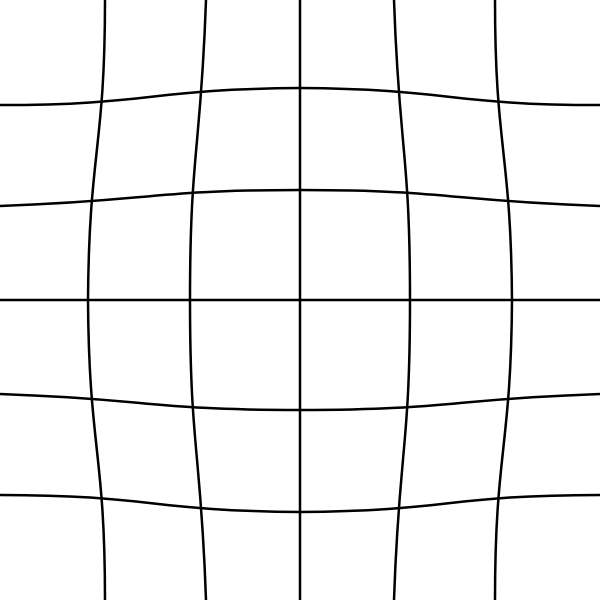

In terms of imaging, distortion is typically divided into several main categories. Barrel distortion causes the central area of the image to expand, making straight lines bend outward at the edge of the image. In contrast, pincushion distortion causes the central area to contract, making straight lines bend inward. Another less common type is mustache distortion, which combines the characteristics of barrel and pincushion distortion to form complex shape distortions. These types of distortions have different manifestations in various optical systems, and understanding their features is crucial for improving imaging quality.

Read related post> The Advantages of Telecentric Lens

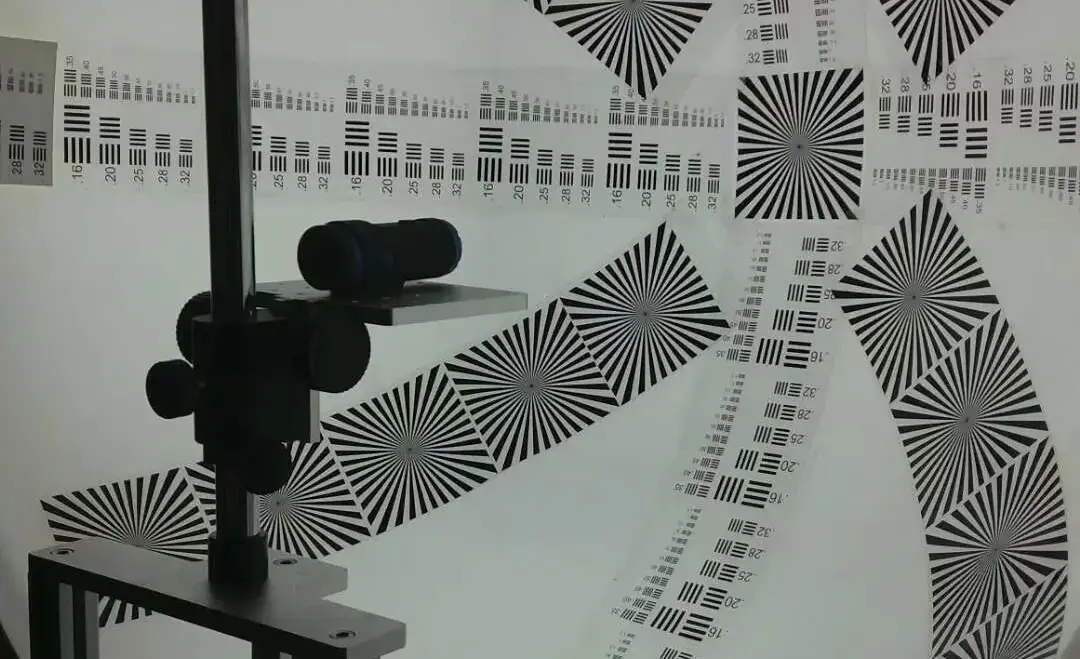

Measuring MTF and distortion

The method of measuring MTF mainly relies on various tools and techniques, the most common of which include MTF charts and software analysis. MTF charts visually demonstrate the performance of the system at various frequencies by measuring the contrast of the optical system at different spatial frequencies. These charts provide key data for optical designers and engineers to help evaluate and improve lens performance. In addition, many new software analysis tools can also conduct MTF measurements, automatically generating MTF curves through image processing algorithms, providing more detailed and accurate analysis. The combination of these technologies evaluates optical system performance more comprehensively and efficiently.

Common techniques for measuring distortion include geometric shape testing and software analysis. Geometric shape testing evaluates the degree of distortion by capturing specific calibration patterns and analyzing the shape changes of these patterns in the image. Software analysis uses image processing tools to quantify the type and degree of distortion by comparing the image with the reference pattern. These evaluation methods not only help identify distortion but also provide a basis for subsequent image correction.

Improving imaging quality

- Lens selection

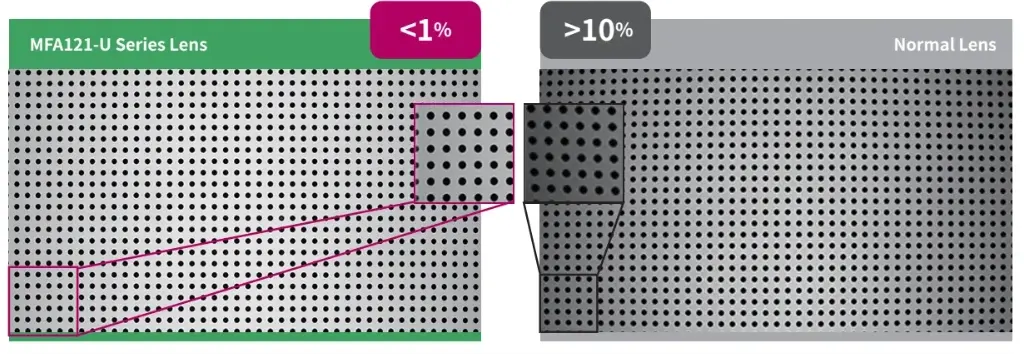

High-quality lenses can significantly improve the reproduction ability of images’ clarity and detail. When selecting lenses, their optical design, materials, and coating properties should be considered. For example, low-dispersion glass and high-transmittance coatings can effectively reduce chromatic aberration and reflection loss, thereby improving the MTF value. In addition, appropriate focal length and aperture design can also affect the sharpness and background blur effect of imaging. Therefore, when selecting a lens, it is necessary to fully evaluate its MTF curve to ensure the selected lens has the best performance in the target application scenario.

- Design improvements

The optimization of lens design is another important part of improving imaging quality. By applying advanced optical design software, engineers can simulate the combination of different optical components and optimize the shape, arrangement, and material of the lens. The optimization usually includes distortion and aberration analysis, ensuring that the MTF curve remains within the ideal range under different working conditions. Studies have shown that good optical design can not only improve image clarity but also reduce light loss and enhance the adaptability of the imaging system in complex environments. Through comprehensive optimization of the optical system, imaging quality can be significantly enhanced to meet stringent requirements.

- Post-processing techniques

Post-processing algorithms also play an essential role. Advanced image processing algorithms can effectively correct distortions and other defects that occur during the imaging process. For example, using de-distortion algorithms can correct geometric distortions in the image, while algorithms that enhance contrast and sharpness can improve the detail performance of the image. In addition, image processing tools, coupled with deep learning can automatically identify and correct various imaging defects, leading to a more comprehensively improved imaging quality. These post-processing techniques, combined with high-quality lenses and optimized designs, can provide excellent visual effects for AOI and other applications.

Read related post> A Journey to Methods for Excellent Imaging

Conclusion

In the process of improving image quality, there are various ways to improve distortion and effectively increase MTF values. Generally speaking, lens selection, design optimization, and post-processing algorithms are inseparable. High-quality lenses are the foundation, and their optical performance directly affects the clarity and detail reproduction of the image. Design optimization reduces distortion and aberration through scientific optical design, guaranteeing that the system performs well under various conditions. Post-processing algorithms provide flexibility and accuracy for improving image quality, correcting defects, and enhancing details for higher imaging quality. The comprehensive consideration of these three ways not only improves imaging quality but also ensures reliability and accuracy in industrial automation and other fields, bringing users a more efficient and accurate visual experience.