Machine vision in manufacturing – an overview

Machine vision is a technology that enables machines to visually perceive and interpret the world around them using imaging, sensors, and artificial intelligence algorithms. It allows automated systems to capture, process, and analyze images or video in order to make decisions or perform actions based on visual input.

In modern manufacturing in 2024, machine vision plays a crucial role in ensuring product quality, optimizing production efficiency, and enhancing overall processes.

Machine vision systems provide precise, consistent, and reliable inspection capabilities, detecting even minor defects that may be missed by human inspection.

Automation of quality control processes using machine vision leads to higher accuracy, reduced error rates, and improved product quality.

Machine vision systems can easily adapt to different products, configurations, and production requirements, offering flexibility in manufacturing environments where frequent changeovers are necessary.

The ability to reconfigure machine vision setups quickly allows manufacturers to scale production, introduce new products, and respond to market demands with agility.

While initial implementation costs can be significant, machine vision systems often lead to long-term cost savings by reducing labor costs, minimizing waste, and improving overall productivity.

Enhanced quality control and reduced error rates result in fewer product defects, lower rework costs, and increased customer satisfaction.

The importance of machine vision in QA process

Machine vision is a vital integration in quality assurance for modern Industry 4.0 as it enables automated, consistent, and high-speed quality assurance, leading to improved product quality, increased productivity, and cost savings for industrial operations:

- Automated Inspection:

Machine vision systems can automatically inspect products, components, or processes with high speed and accuracy. This allows for continuous monitoring and rapid detection of defects or deviations from specifications, improving overall product quality.

- Consistent and Objective Evaluation:

Machine vision systems provide consistent and objective evaluation, unlike human inspectors who may be subject to fatigue, bias, or inconsistency. This ensures a more reliable and repeatable quality assessment.

- High-Speed Inspection:

Machine vision can perform inspections at much higher speeds compared to manual inspection, enabling faster production and processing lines.

- Reduced Human Error:

Automating the inspection process using machine vision reduces the risk of human errors, which can be costly in terms of product quality, waste, and rework.

- Traceability and Data Analytics:

Machine vision systems can capture detailed data about the inspection process, which can be used for traceability, process optimization, and predictive maintenance, aligning with the goals of Industry 4.0.

- Flexibility and Adaptability:

Machine vision systems can be programmed to inspect a wide range of products, components, or processes, making them versatile and adaptable to changing production requirements.

- Cost-effective:

Automating quality assurance with machine vision can save cost by reducing labor, improving efficiency, and minimizing product defects and rework.

Read related post> Mastering Machine Vision: How to Select the Ideal Industrial Camera?

The vital role of quality control in industry automation

QA is not just a necessary function but a strategic imperative for industry automation. It ensures that the benefits of automation, such as increased speed, efficiency, and cost-effectiveness, are fully realized without compromising product quality and customer satisfaction. The main feature of industry automation is high-volume, high-speed production, but without effective QA, the risk of producing defective or non-conforming products increases significantly and thus defeats the whole purpose of automation.

Besides, many industries have strict regulatory requirements and quality standards that must be met. Effective QA is essential for ensuring compliance and avoiding costly penalties or product recalls. On top of that, delivering high-quality products consistently is crucial for maintaining customer satisfaction and protecting a company’s brand reputation.

Automated production without robust QA can lead to dissatisfied customers and potentially damage the company’s market standing.

The challenges of traditional QA methods

Traditional QA methods heavily rely on human laborers and their experience/expertise, also their work ethics and fatigue. There are quite a few points as to why modern industry automation relies on machine vision rather than the old ways:

- Scalability:

Traditional QA methods, such as manual inspections, can struggle to keep up with the high production volumes and rapid pace of automated manufacturing.

As production scales, the limitations of manual QA become more apparent, leading to bottlenecks and potential quality issues.

- Consistency and Objectivity:

Human inspectors can be subject to fatigue, bias, and inconsistency, which can compromise the reliability and repeatability of quality assessments.

Automated systems can provide more consistent and objective evaluation, reducing the risk of human error.

- Speed and Responsiveness:

Traditional QA methods, such as physical sampling and laboratory testing, can be time-consuming, leading to delays in the production process.

In fast-paced, automated environments, the need for rapid quality feedback and decision-making is critical.

- Data Collection and Analysis:

Traditional QA methods often rely on manual data collection and analysis, which can be labor-intensive and prone to errors.

The vast amounts of data generated by automated production systems require more sophisticated data management and analysis capabilities.

- Integration with Automation:

Integrating traditional QA methods with automated production systems can be challenging, as they may not be designed to work seamlessly together.

This can lead to communication gaps, data silos, and inefficiencies in the overall production workflow.

- Flexibility and Adaptability:

Traditional QA methods may not be easily adaptable to changing product designs, materials, or production requirements, which are common in modern manufacturing.

Automated systems can offer more flexibility and the ability to quickly adapt to new quality requirements.

- Skill Shortages:

Highly skilled quality professionals are in high demand, and finding and retaining them can be a challenge, especially in the face of rapid technological changes.

Automating QA processes can help address the skills gap and free up human resources for more strategic quality-related tasks.

The advantages of automated optical inspection in QA

Compared to traditional methods, AOI with machine vision technologies offers significant advantages in factory automation (FA), not only it is way more consistent, reliable, efficient and traceable, it also can enhance product quality, improve process efficiency, increase productivity, and maintain a competitive edge in the market. The combination of automated inspection and data-driven quality management enables a more robust and responsive approach to quality assurance in modern industrial environments.

- Improved Inspection Speed and Throughput:

AOI systems can perform inspections at much higher speeds compared to manual visual inspections.

This increased inspection speed allows for higher production throughput and reduced bottlenecks in the manufacturing process.

- Consistent and Reliable Quality Assessments:

AOI systems provide consistent, objective, and repeatable quality assessments, eliminating the variability and potential biases associated with human inspectors.

This ensures a more reliable and accurate evaluation of product quality.

- Reduced Human Error:

By automating the inspection process, AOI systems eliminate the risk of human errors, such as fatigue, distraction, or subjective judgment.

This leads to a reduction in the number of defective products and the associated costs of rework or waste.

- Real-Time Feedback and Process Control:

AOI systems can provide real-time feedback on the production process, enabling immediate corrective actions to be taken.

This allows for tighter process control and the ability to quickly identify and address quality issues.

- Traceability and Data Analytics:

AOI systems generate detailed inspection data that can be used for traceability, process optimization, and predictive maintenance.

This data-driven approach supports continuous improvement efforts and helps manufacturers make more informed decisions.

- Flexibility and Adaptability:

AOI systems can be programmed to inspect a wide range of products, components, or processes, making them versatile and adaptable to changing production requirements.

This flexibility is crucial in the face of evolving product designs, materials, or manufacturing processes.

- Cost Savings:

Automating the inspection process with AOI can lead to cost savings by reducing labor costs, minimizing product defects and rework, and improving overall production efficiency.

- Compliance and Regulatory Requirements:

AOI systems can help manufacturers meet stringent quality standards and regulatory requirements, ensuring the integrity of their products and processes.

Read related post> The Revolutionary Impact of FA Lenses in AOI Applications During Crystal Growth Processes

Some case studies of AOI in factory automation

2.5D/3D glass side cover/panel inspection

When detecting defects on glass side cover in display panel manufacturing, it is important to make sure your industrial lens has a large FoV to allow better inspection on multiple layers.

COOLENS®’ WWK series features a high-resolution telecentric lens that supports 5M-25M pixel cameras; with plenty of magnification options available and a larger field of view plus the built-in coaxial illumination port.

This series is the ideal choice for AOI applications such as display panels, semiconductor products or tiny code reading scenarios.

The long working distance feature coupled with high resolution allows engineers more freedom in designing their inspection system.

The maximum WD of some lens models from the WWK series can go up to 220mm.

The WWK series supports sensor sizes up to 1.1″ with up to 25 MegaPixels.

Read related post> COOLENS’ Telecentric Lens Inspection in the Display Panels

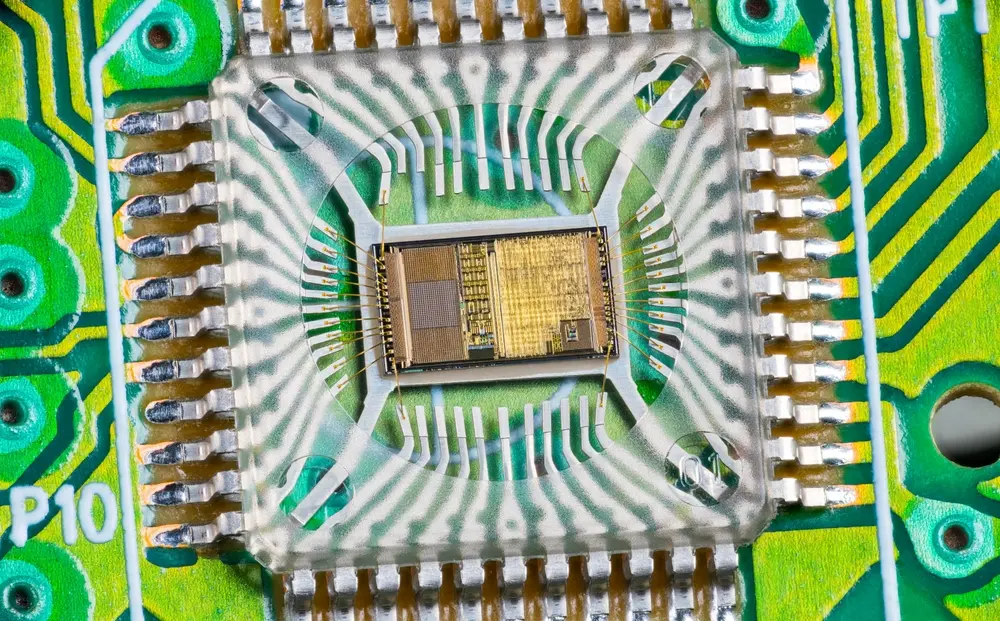

IC Packaging QA

The new trend of 2.5D/3D semiconductor packaging technologies has issued a new challenge for inspection cameras – as the stacking process now requires the lens to accurately capture visual data not only on width/length, but also on the 3rd dimension of height.

The new trend of 2.5D/3D semiconductor packaging technologies has issued a new challenge for inspection cameras – as the stacking process now requires the lens to accurately capture visual data not only on width/length, but also on the 3rd dimension of height.

The 2.5D and 3D packaging is done by stacking IC dies on an interposer or even one another for multiple layers, greatly reducing footprints and size while increasing density and heat efficiency.

The traditional industrial lens used for IC packaging inspection now needs to keep up! Fret not! With the new WH04 Series and its long WD and large DOF, you can easily fit a robotics arm or other actuators while maintaining excellent imaging qualities on every stacking dies and their angles and positioning.

As the designated lens for IC inspection by multiple industry leaders, the WH04 series is capable of meeting inspection needs for the most cutting-edge packaging trends, including CoWoS. Our in-house optics experts also provide extensive technical support including result image lab testing, providing total solutions and extensive after-sales consultation and adjusting. We have global offices covering countries and regions like South Korea, Germany and more.

Read related post> Introducing WH Series-A New Lens For A New IC Packaging Era

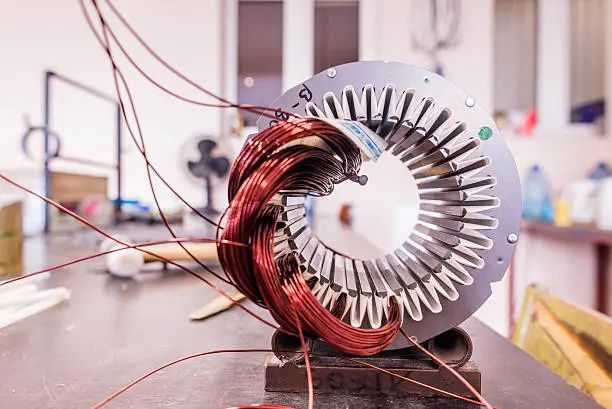

Automotive manufacturing (Motor stator & connector)

Automotive connector QA testing:

By utilizing our DTCM series lenses, you can inspect multiple features including PINs simultaneously, without having to take multiple photoshots thanks to the large DoF, high telecentricity and low distortion design, greatly improving your QA testing efficiency.

Motor stator burr inspection:

Our DTCM series lenses can inspect even the tiniest burr in motor stator inspection, which is an essential QA part of automotive manufacturing. Due to the small size nature of the motor stator burr, our DTCM series is designed specifically to have a large aperture with high telecentricity and extra higher object space telecentric FOV to help you inspect miniature irregulars such as burrs.

The series also helps in motor stators measuring, the high level of light throughput thanks to the big aperture allows better contrast in the imaging result, which makes the inspection algorithm easier to handle and more efficient; high telecentricity enhances perspective and allows for more accurate measurements.

Conclusion

Machine vision is a vital technology that is transforming modern manufacturing in 2024.

By enabling automated, consistent, and high-speed quality assurance, machine vision systems play a crucial role in ensuring product quality, optimizing production efficiency, and enhancing overall industrial processes.

Automated Optical Inspection (AOI) is a key application of machine vision that offers significant advantages over traditional quality assurance methods. AOI systems provide faster inspection speeds, more reliable and objective evaluations, reduced human error, real-time process feedback, and enhanced data analytics capabilities.

The integration of machine vision and AOI into industry automation is driving cost savings, improved productivity, and increased competitiveness for manufacturers in the era of Industry 4.0.