Overview

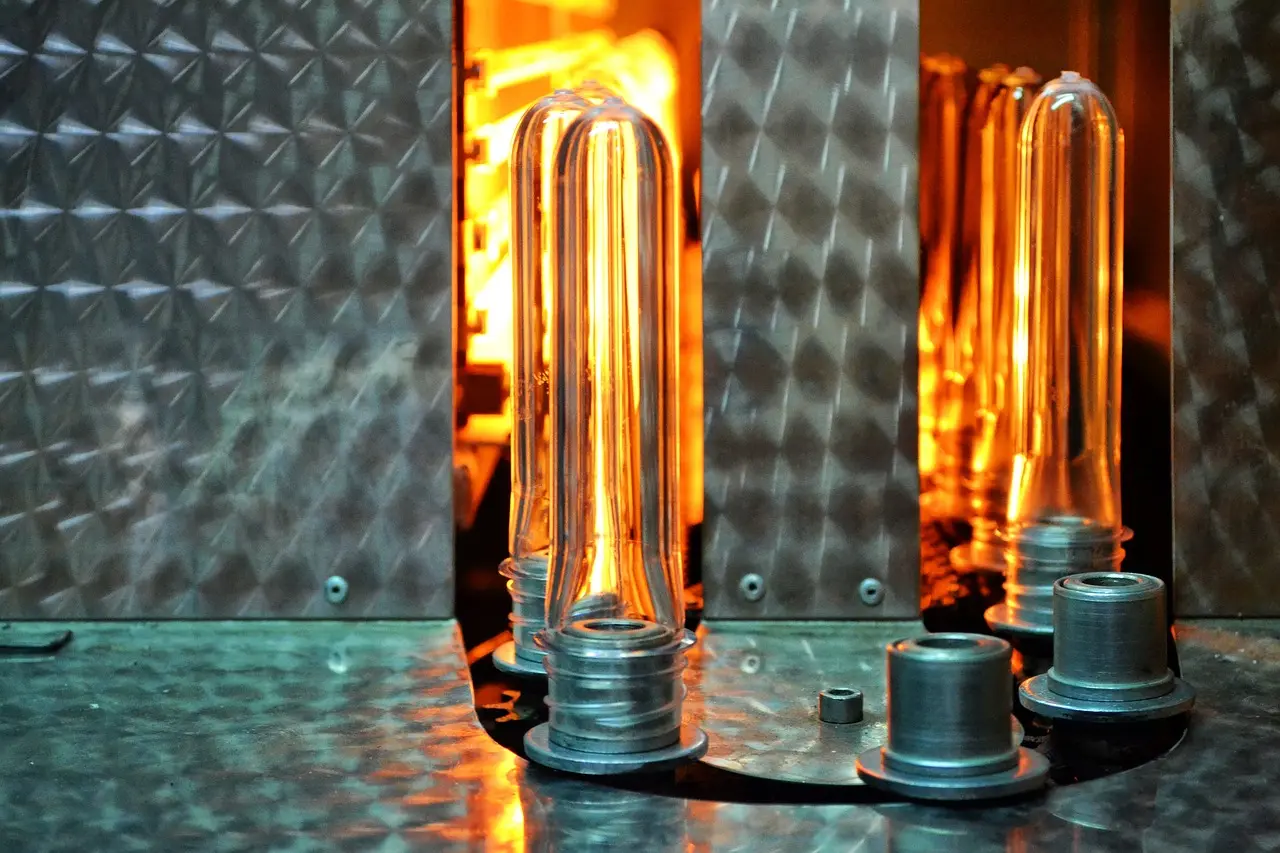

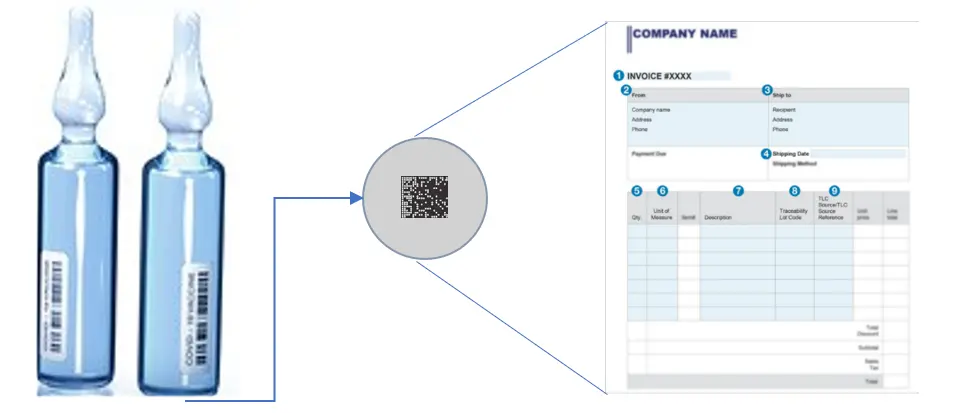

Aerospace, pharmaceuticals, and other industries have always been subject to strict legal regulations, with stringent requirements for traceability of raw materials, components, and finished products. Faced with these demands and challenges, pharmaceutical companies have been actively exploring various solutions for traceability throughout the pharmaceutical lifecycle. Pharmaceutical packaging is a crucial part of the pharmaceutical industry, and the traceability of glassware used for medicine bottle packaging (ampoules, vials, syringes) is crucial. Using laser-engraved tiny two-dimensional codes (minimum of 14 characters in a 1x1mm code) on the bottles is essential for marking products. This method, compared to traditional labeling, offers more advantages in post-processing. Laser marking is more stable during subsequent processes like filling and withstands washing, high-pressure sterilization, and nitrogen purging at 600°C. It is more resistant to wear and particle contamination during handling and storage. Laser marking is projected to gradually replace traditional labeling.

The Challenge

After laser printing on the assembly line, the printed QR code is inspected to check if the information is missing and if there are any defects in the appearance (bubbles, burning, black smoke, etc.).

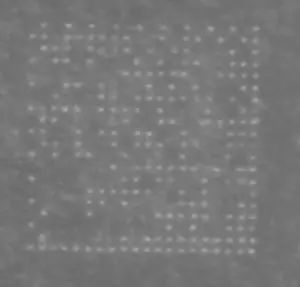

Limited by the small size of the ampoules, the printed QR codes are much smaller (less than 1 mm), and some of them have more than 14 bits, similar to the panel industry. Besides, the ampoules are transparent glassware, so the background is complex, requiring a lens with high resolution, shallow depth of field, and high contrast.

The Solution

After being informed of customer requirements, technical evaluation is usually divided into two steps: sample inspection and evaluation, test solution.

Step one: sample inspection and evaluation

In this step, this application gives a general picture of laser code printing on ampoules.

QR code printing is a crucial factor in determining whether an ampoule is qualified. Whether there is dirt, adhesion, bubbles, burning, or black smoke on the surface of the QR code is an important basis for judging the coding effect. Therefore, in this application, we first review the ampoule samples, evaluate the material, size, and bottle codes of these samples to identify specific issues to be solved, and then determine whether the lens series meets the requirements.

Next, we will make a customized solution based on the sample characteristics and requirements.

Step two: test solution

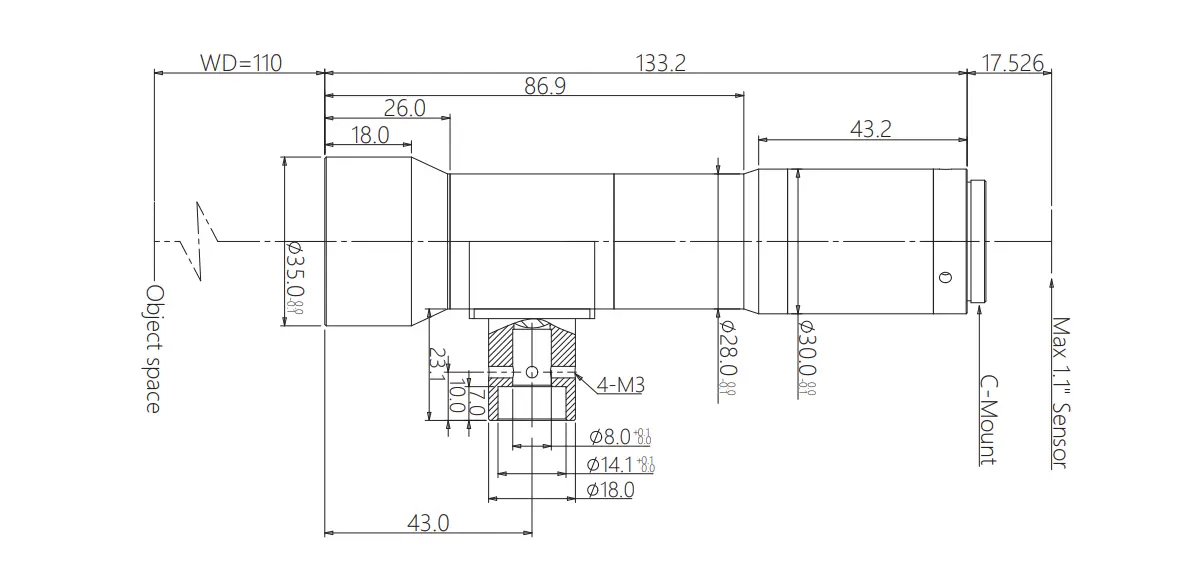

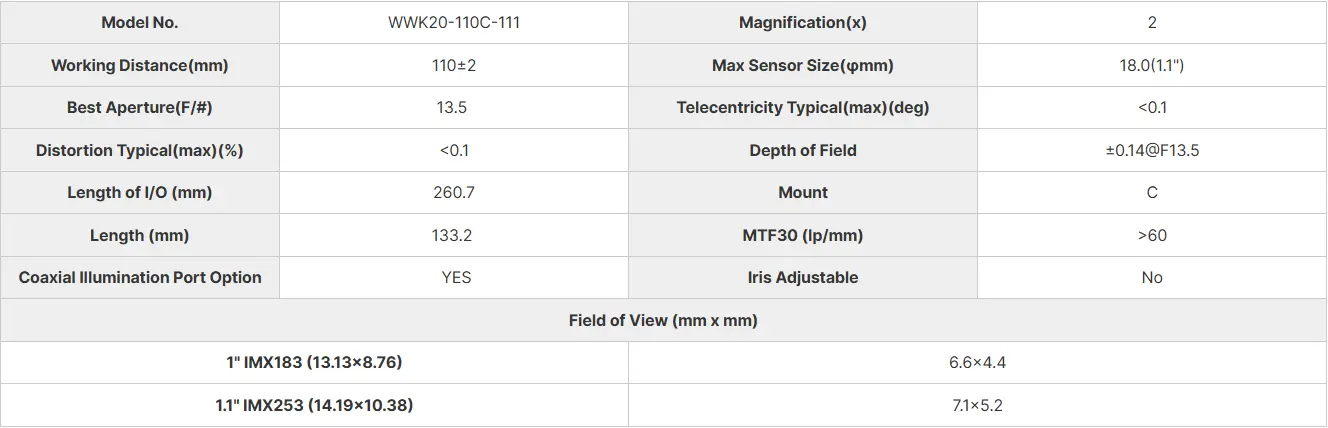

- Lens: COOLENS® WWK20-110C-111

- Light source: ring lights or coaxial lights

According to the product code printing position, a visual inspection system is set up on one side of the line to take pictures. A 21MP camera is used with a ring light or coaxial light to take pictures and detect the QR code area.

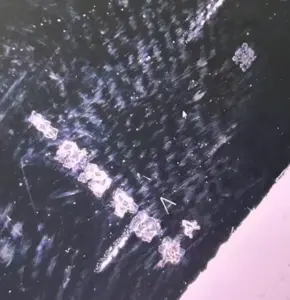

Usually, in the laser code printing process, there are certain requirements for working distance, environment, and power. These factors will cause blurring, adhesion, bubbling, burning, black powder adhesion, and other problems with the QR code. By adding visual inspection after the printing workplace to detect the defects of the QR code, the dirt and flaws on the bottle body, abnormal production status can be detected in time, and parameters can be adjusted real-time to avoid waste of resources caused by manufacturing abnormalities.

The WWK series is the optimal choice due to its long working distance and high resolution, providing engineers with greater flexibility in designing their inspection systems. Some lens models from the WWK series offer a maximum working distance of up to 220mm and support sensor sizes up to 1.1″ with up to 25 MP.

In addition, with built-in coaxial illumination port, this type of lens can be used along with coaxial light or ring light. Furthermore, this high-telecentric lens features low distortion of below 0.1% and high resolution, ensuring precise inspection.

Results and benefits

The following are the overall results of how these three features affect the inspection of QR codes on ampoules.

- High resolution: The printed QR codes are tiny and complex. Using a lens with high resolution ensures that the details of the QR codes are clearly visible and easy to be recognized, avoiding issues of blurriness and adhesion. Low distortion and high telecentricity of this lens produce high-precision images.

- Long working distance: Multiple magnification options make scenarios that require long working distance possible, allowing inspections without interfering with the production line, thus providing greater flexibility and reducing layout constraints. In doing so, the design of long working distance minimizes system space and gets costs down.

- Shallow depth of field: A shallow depth of field enables precisely focusing on the QR codes, eliminating background distractions and ensuring accurate inspection, which helps to efficiently identify potential defects.

Conclusion

In the previous section ‘Solutions and implementations’, a specific solution was formulated according to the size, glass material, complex background, and manufacturers’ inspection requirements of ampoules. Coupled with coaxial or ring light, this lens with high resolution, low distortion, long working distance, and shallow depth of field comprehensively enables Automated Optical Inspection (AOI) to accurately capture complete and clear code images during the manufacturing process, and also identify the defects of QR codes.