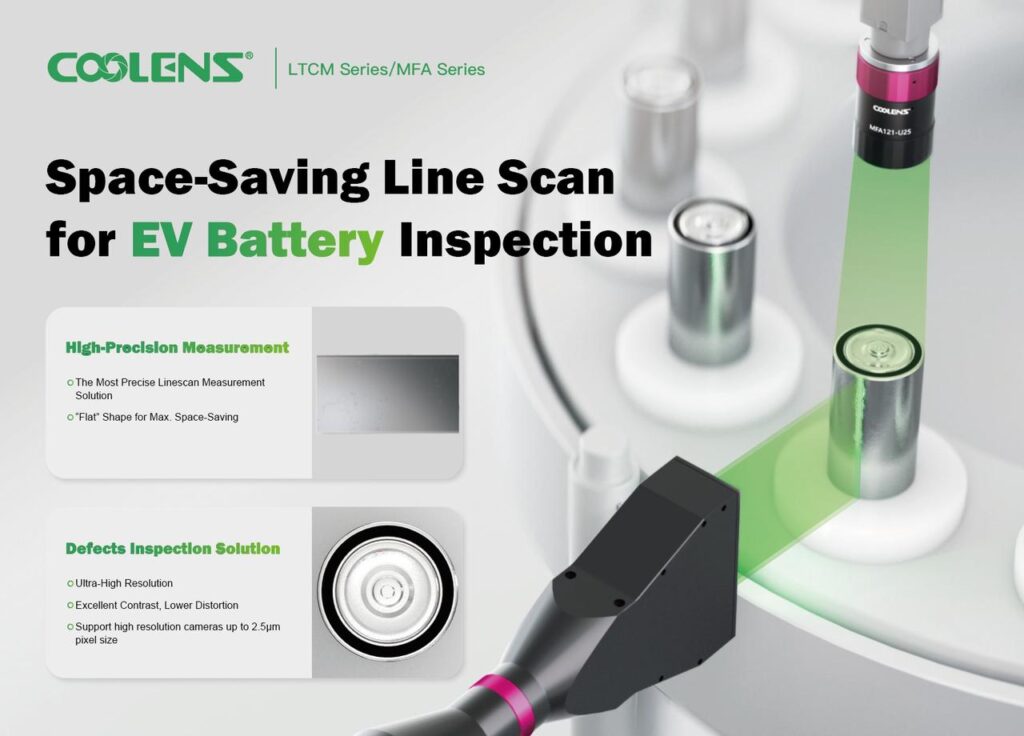

Demand for electric vehicles (EV) is growing rapidly. To meet that demand and consumer expectations, manufacturers must focus on reliable and stable production processes to minimize waste and increase quality. Therefore, EV battery’s automated optical inspection(AOI) is turning into a hot topic.

With high-precision measurement and defect inspection, VICO lmaging space-saving line scan solution for EV battery inspection helps manufacturers:

– Adhere to the highest quality inspection standards

– Ensure battery performance

– Maximize throughput

– Reduce potential recalls

By integrating VICO’s lenses into the AOl process, manufacturers can efficiently detect even the tiniest defects on EV batteries’ surfaces, like scratches, smudges, and edge breakage, but also effect high-precision dimensional measurement.

EV battery

|

|

| High-Precision Measurement | |

| The most precise line scan measurement solution |

|

| "Flat" shape for max.space-saving | |

| Fit common line scan interfaces. additional mounts available upon request. | |

| View Details | View Details |