Overview

With the automobile industry’s rapid development, wheel hubs’ output is growing continuously. As the supporting component of the automobile, the wheel hub carries the weight and all loads of the vehicle and therefore is an important guarantee for vehicle safety. Its quality is closely related to driving safety. The valve port can prevent air pressure accumulation, help release excess air, and prevent excessive pressure from affecting stability or causing deformation. In addition, the main function of the valve port is to secure the wheel hub to the axle. The valve port fastens the wheel hub to the wheel hub seat of the axle through bolts for safe and stable installation of the wheel on the vehicle. In summary, ensuring the quality control of the wheel hub, valve ports, and bolt holes is crucial to guaranteeing the safety and performance of the vehicle.

In the past, automobile wheels were mainly inspected manually, leading to low efficiency and the inability to guarantee accurate results. With the continuous development of AOI (Automated Optical Inspection), people have gradually realized the important role of machine vision in wheel inspection. AOI is crucial in the automotive industry, especially for quality control. Besides, the wheel hub is an important part of an automobile. Its accuracy directly impacts the vehicle’s safety and driving stability. But now the inspection of the valve ports or bolt holes of wheel hubs poses several challenges, which are discussed in the next section.

The challenges

High accuracy and consistency: Whether it is a bolt hole or a valve port, their dimension and shape must be very accurate for correct installation of the bolt and the sealing of the bolts. Any deviation in dimension or shape may cause unstable installation or air leakage, which may bring safety hazards. Therefore, the inspection system needs extremely high accuracy.

Precise positioning: Bolt holes should be at the same height as the overall design height of hubs for correct alignment. The same requirement for valve ports to avoid disturbing other components.

Surface reflection and roughness: The metal material of the hub may cause reflection or rough texture on its surface, which will interfere with the imaging effect of the visual inspection system, resulting in a decrease in inspection accuracy or misjudgment.

Complex geometry: The wheel hubs tend to have complex geometry. Bolt holes and valve ports may be located on curved or inclined surfaces, increasing inspection difficulty. The inspection system needs to handle complicated shapes to ensure precise inspection of every hole.

Diversity and adaptability: There are significant differences among various models of wheel hubs in terms of the number, size, spacing, and position of bolt holes and valve ports. Therefore, the visual inspection must be flexible enough to adapt to these differences and ensure accuracy in various hub designs.

Real-time inspection and manufacturing efficiency: Inspection of finished wheel hubs usually needs to be carried out on high-speed production lines, so not only high precision but also fast inspection is required.

The solutions

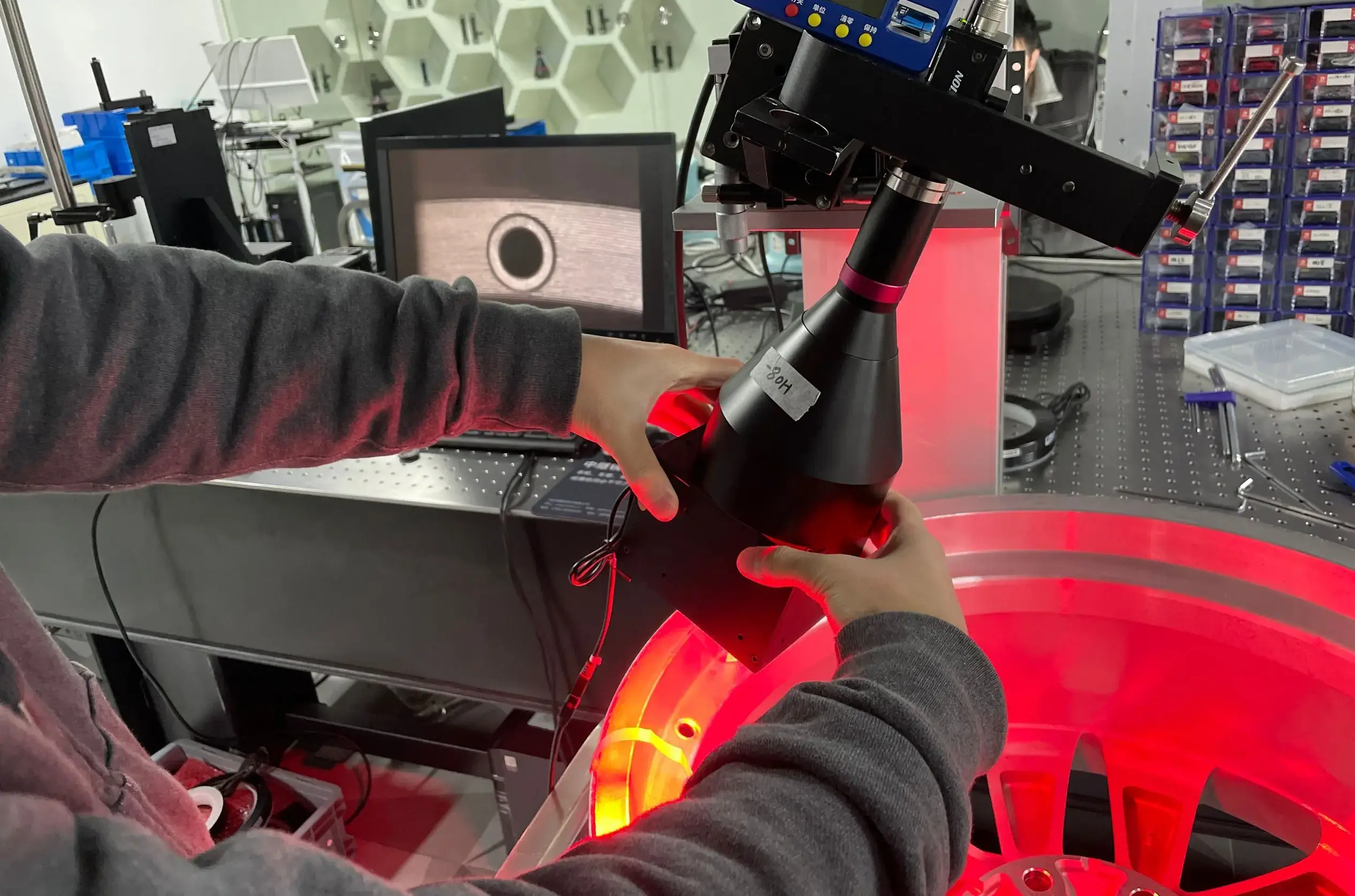

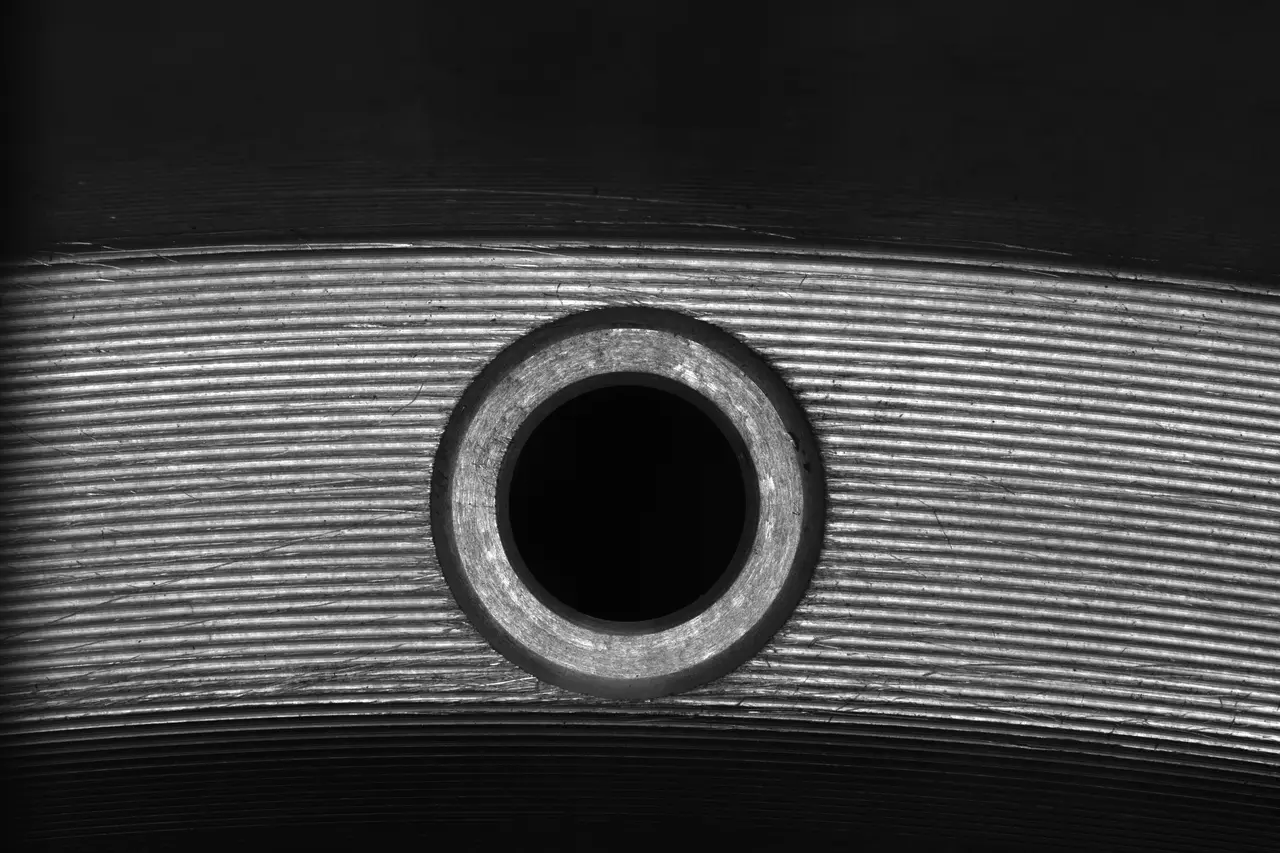

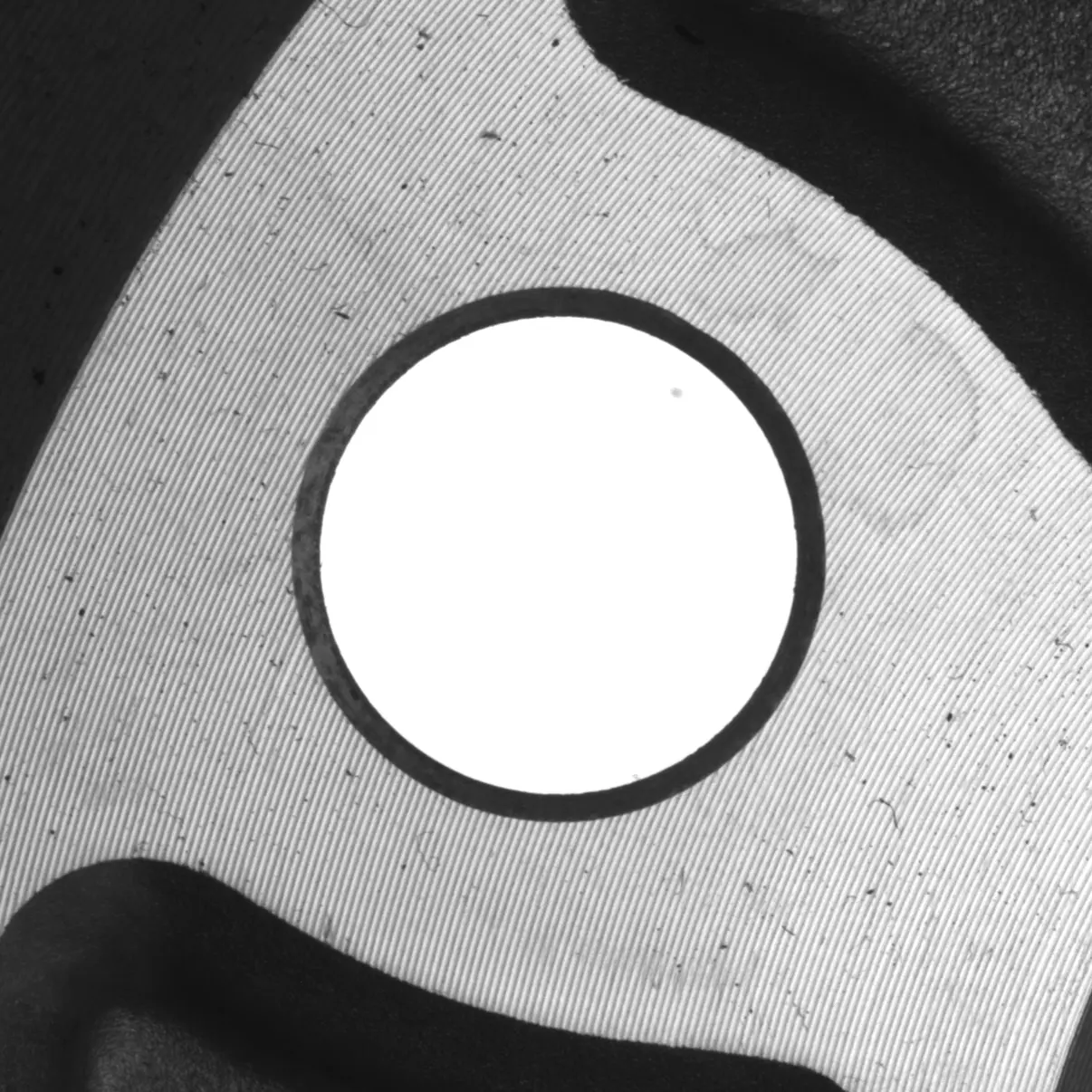

The valve port inspection

Inspection background: Made of metal, the valve port may reflect light.

Inspection requirements: Inspect whether the dimension of the hub valve port is wrong and whether the position is deviated.

Camera: 1″, 2000W, 2.4um

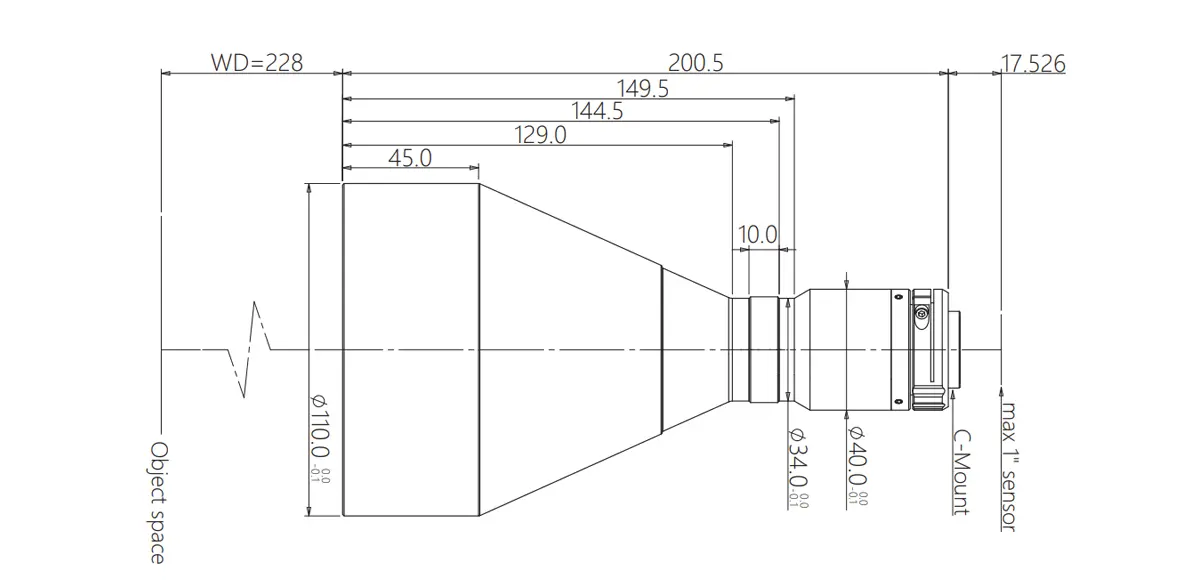

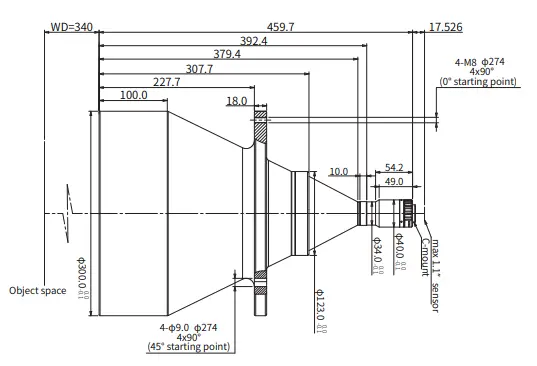

Lens: DTCM110-80H-AL

Light source: Red external coaxial light

Angle: Tilt the lens 25° and place the product vertically

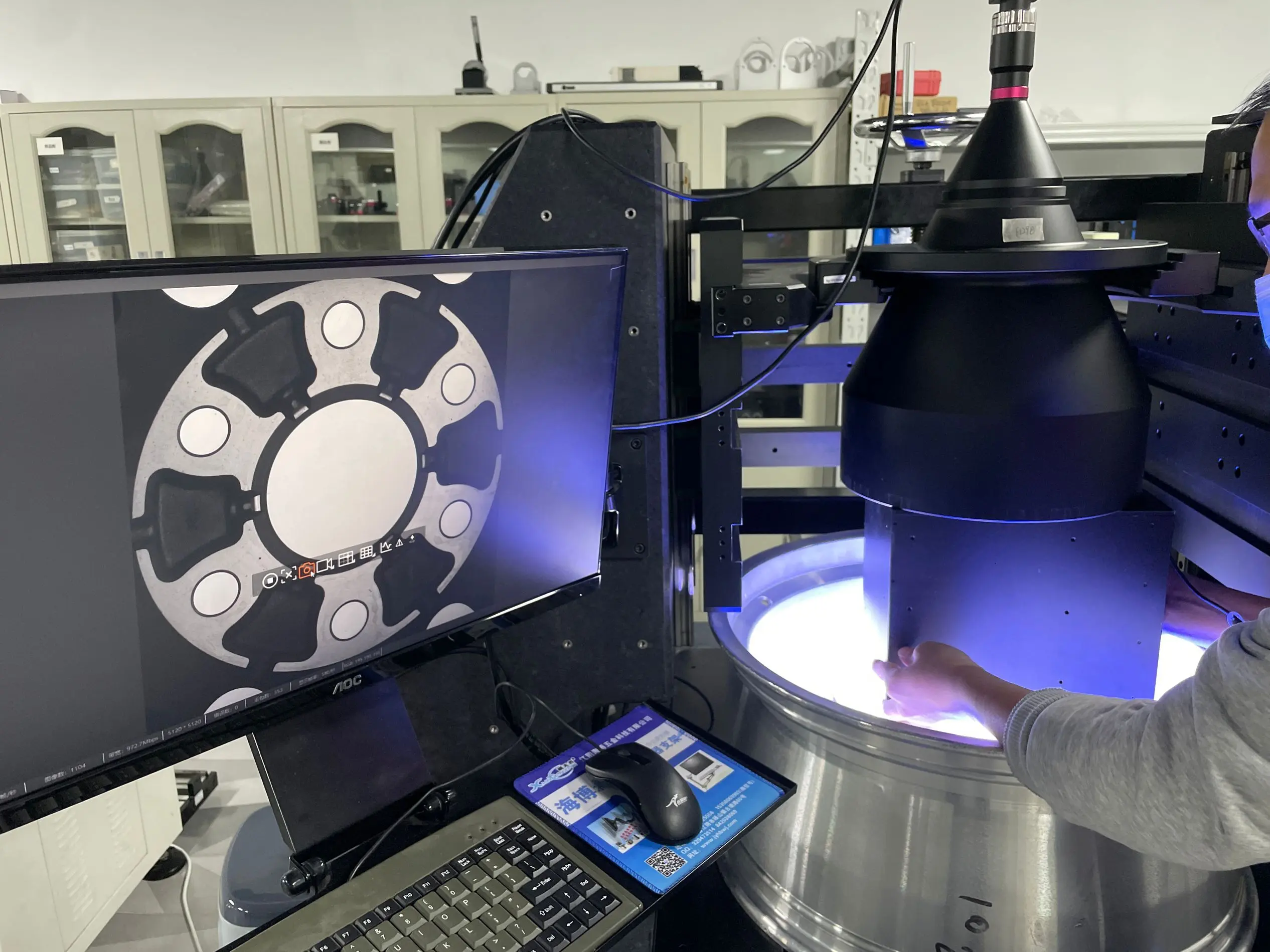

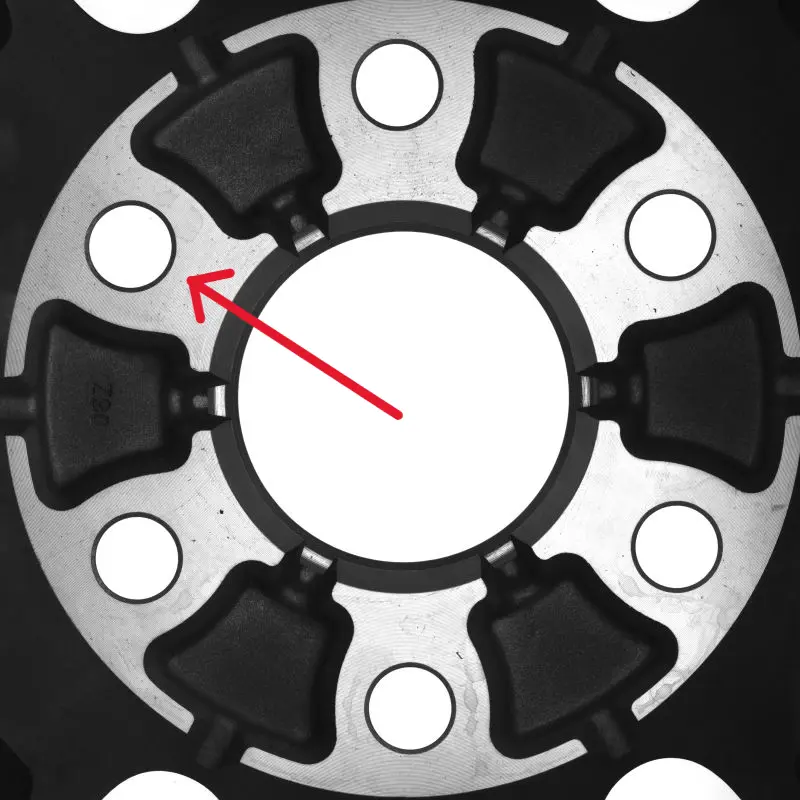

The bolt hole inspection

Inspection background: Six bolt holes are widely distributed on the large hub, so a lens with a large FOV is needed, and made of metal, the hub may reflect light.

Inspection requirements: Check if the dimensions of bolt holes meet the standard and if these holes are positioned correctly and are evenly distributed.

Camera: 1.1″, 2500W, 2.5um

Lens: DTCM111-258-D39-AL

Light source: blue backlight and white external coaxial light (flush with the lens)

Benefits and results

We choose the DTCM series for the following reasons:

- High resolution: For automotive wheel hub inspection, we have selected the DTCM series with a resolution of up to 150 MP and MTF30 (lp/mm) > 150. So it helps us capture every detail of valve ports and bolt holes, which means more precise images are produced to measure hole diameter and position accurately.

- Large FOV: Six bolt holes are evenly distributed in the large area of this wheel hub. The FOV of the DTCM series lenses is between 26mm-300mm. So with a large FOV, the DTCM series can cover all bolt holes during inspection to ensure they can be shot at one time. In doing so, it helps identify whether there is a deviation in the position of the bolt hole in the future while reducing the number of shots and improving efficiency.

- Low distortion: This feature improves measurement accuracy by ensuring precise measurement of the position and dimensions of holes.

- Long WD: As is demonstrated in the onsite pictures above, our series has quite a long WD. During inspection, operators can perform tasks within a longer working distance without having to probe the lens into the inspected object to avoid physical contact.

- Large image circle: With a large image circle, our lenses are compatible with sensors up to 67.6mm and cameras with 3.76μm pixel size.

Conclusion

The rapid development of the automotive industry has led to an increase in demand for wheel hubs, which are crucial for vehicle safety. Wheel hubs support the weight and all loads of the car, so their quality is a key factor in ensuring driving safety. Accurate quality control of wheel hubs (including their valve ports and bolt holes) is crucial. Traditional manual inspection methods are inefficient and inaccurate in most cases. However, with the development of Automatic Optical Inspection (AOI), machine vision has become an important tool for wheel hub inspection, ensuring high precision and efficiency.

Our DTCM series provides high-resolution and efficient solutions for wheel hub inspection, solving key problems such as imaging accuracy, surface reflection, and complex geometries. By accurately inspecting valve ports and bolt holes, the safety and performance of the entire vehicle are improved. AOI lenses, such as the DTCM series, improve quality control, revitalize the automotive manufacturing industry’s quality control, and drive technological advancement and industry growth.