What is telecentric lens?

The telecentric lens is mainly designed to correct the parallax of traditional industrial lenses. It maintains unchanged image magnification over a range of object distances. This is important in cases where the object to be inspected is not on the same object surface. Because of their unique parallel ray design, telecentric lenses have been chosen for machine vision applications with strict standards for low distortion.

Types of telecentric lens

Telecentric lens design aims to eliminate the magnifications caused by different distances between the inspected objects and the lens. According to different design principles of telecentric lens, they can be classified as object-space telecentric lens, image-space telecentric lens, and bi-telecentric lens.

Parameters of telecentric lens

Telecentric lens is advanced optical lens designed to correct the parallax of traditional industrial lenses. Compared to normal lenses, it has absolute advantages in magnification, distortion, parallax, resolution, etc.

Magnification, as a key parameter of telecentric lens, refers to the change of the original imaging area of the photographed object by adjusting the lens. Optical magnification is the magnification of the optical lens. Magnification refers to the ratio of the image size to the actual object size.

In the next section, we will further discuss the advantages of telecentric lens from the aspects of related parameters.

Read related post> Understanding Telecentric Lenses: Revolutionizing Precision in Imaging

Advantages of telecentric lens

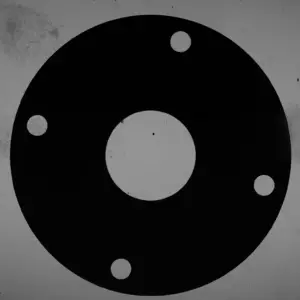

Elimination of parallax

FA lenses have angular fields of view (AFOV) such that the magnification decreases as the distance between the lens and object increases. This is how human vision behaves, and it helps us understand depth. This AFOV causes parallax, also known as perspective error, which decreases accuracy. Because the observed measurement of the vision system will change if the object is moved (even when remaining within the depth of field) due to magnification change. Telecentric lenses eliminate the parallax error characteristic of conventional lenses by having a constant, non-angular FOV. At any distance from the lens, a telecentric lens will always have the same FOV.

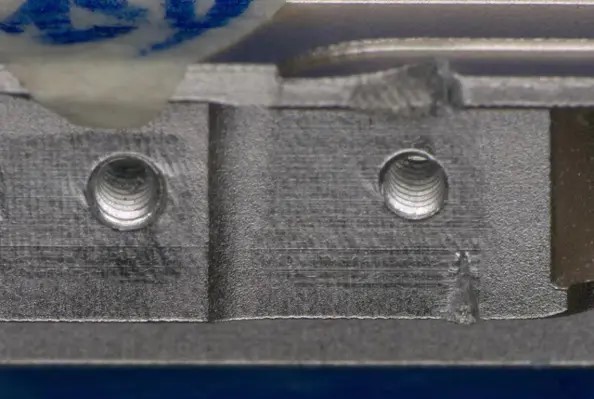

Low distortion

The second advantage of using telecentric lenses is that they usually have lower distortion values than fixed focal length lenses. Distortion makes an object’s actual position appear to be in a different location, thus reducing measurement accuracy.

While it is true that distortion can be calibrated out of images to partially increase accuracy, the parallax is still present and causes errors. Another benefit of not having to correct the distortion from the telecentric lens is that the measurement process can run faster. Because the software requires less computing, lowering CPU load, directly leading to increased system throughput and more parts measured per minute.

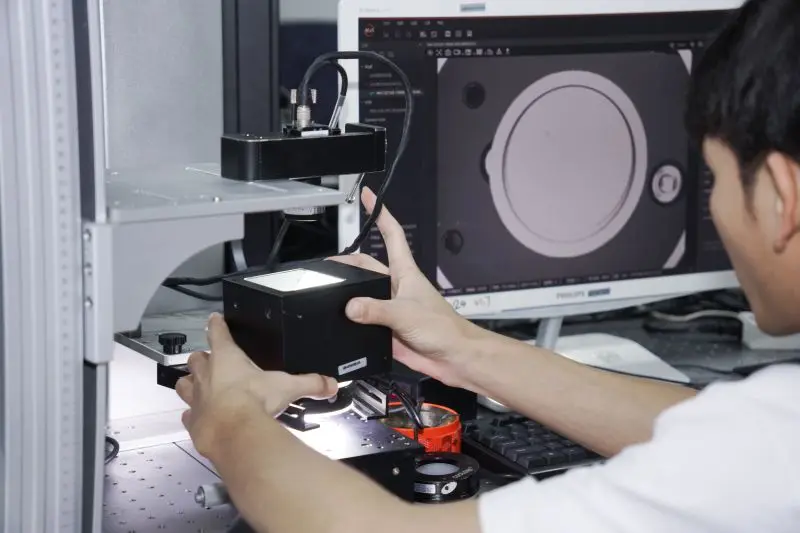

Deep depth of field

Depth of field is the range of distances from the front and back of the object. The aperture, lens, and distance to the object are the important factors affecting the depth of field (DoF).

FA lenses have a relatively shallower depth of field. When the objects to be inspected exceed the range of the lens in the depth direction, inspection or measurement cannot be performed. Lenses with shallower depth of field, especially when used to inspect tiny and intricate objects. This results in blurred images of objects that are not on the same inspection surface. The design of a deep depth of field makes it possible to keep the sharpness and magnification of the image to remain stable within the object distance. Even if the object is moved within the distance in front of the lens, the sharpness of the image will not be significantly decreased.

Therefore, by choosing a telecentric lens with a deeper depth of field, objects with thickness or complex internal structure can be inspected and clear images can be produced.

Light beam pointing stability

Telecentric lenses can effectively control the angle of incoming light and reduce the impact of ambient light changes on imaging. This light stability enables telecentric lenses to provide stable imaging quality when performing inspections in various industrial environments.

Read related post> The Significance of Telecentric System in Machine Vision

How to choose an ideal telecentric lens?

- Clarify application requirements: To choose a suitable telecentric lens, you need to first clarify the application requirements, such as the inspected object, measurement accuracy, working distance, field of view, illumination conditions, working environment, and camera sensor size. Clarifying the requirements helps to define the requirements of lens parameters and illumination selection.

- Understand key parameters: Choosing a telecentric lens requires an understanding of its relevant parameters and effects, such as magnification, working distance, resolution, depth of field, distortion, etc.

- Choose the right type: As mentioned above, there are three types of telecentric lenses. Bi-telecentric lenses have the advantages of both object-space and image-space telecentric lenses. In industrial image processing, object-space telecentric lenses are generally applied, but bi-telecentric lenses are also used.

- Consider camera parameters: The sensor size determines the field of view and resolution of the lens. The pixel size matches the lens resolution. And the lens needs to be compatible with the camera interface. Therefore, when selecting a lens, you need to consider the sensor size, pixel size, and whether the mount of the lens is compatible with that of the camera.

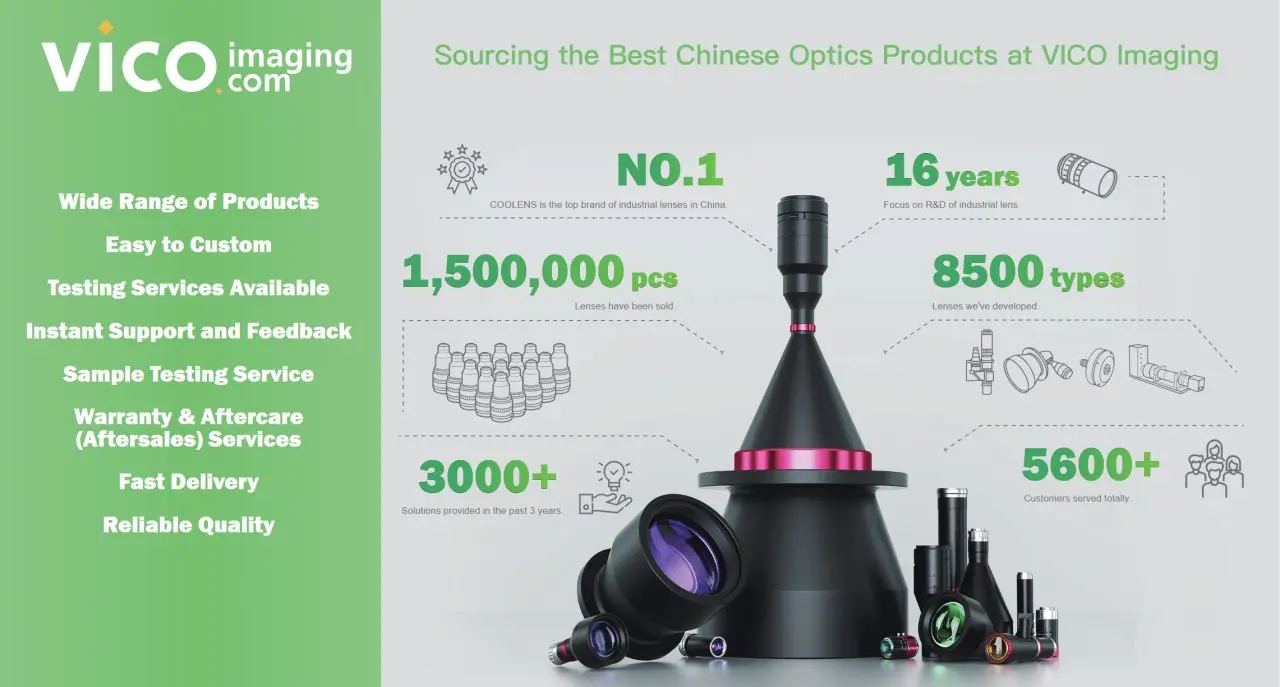

- Purchase suggestions: To choose a suitable telecentric lens, it is recommended to consult professionals and communicate with professional lens suppliers or technicians to obtain more useful advice.

Conclusion

At the beginning of the 21st century, modern industrial development was advancing rapidly, and ordinary lenses could no longer meet the requirements of modern machine vision inspection. Telecentric lenses came into being, to make up for the shortcomings of ordinary lenses and adapt to the needs of precise inspection. Their special design enables them to eliminate parallax, have low distortion, and have a deep depth of field. Currently, the application of telecentric lenses in the field of precise inspection has become one of the key factors in promoting industrial automation and high-precision manufacturing. In the future, the application fields of telecentric lenses will be further expanded to more emerging industries to meet diverse inspection needs.